Developing Self-Healing Polymer Materials That Enhance Flexibility and Prevent Lead Contamination

Replacing Fragile Glass to Prevent Heat and Moisture Leakage

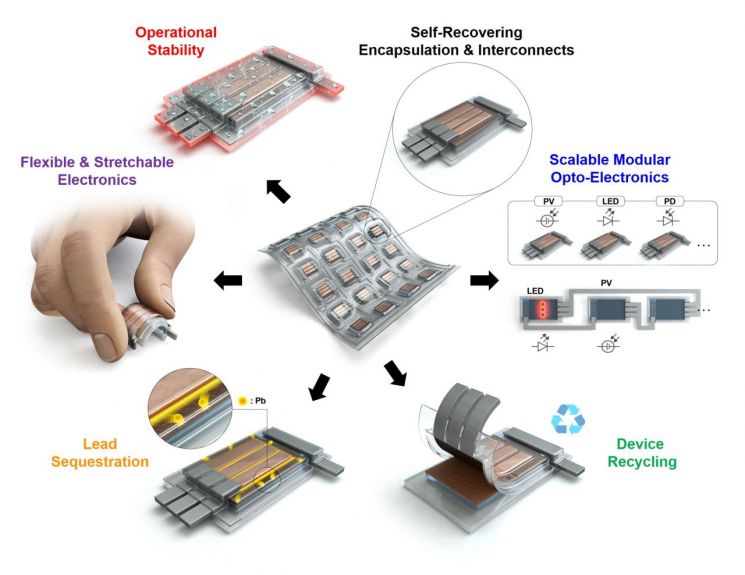

<Encapsulation Process of Perovskite Photovoltaic Devices Using Self-Healing Polymers>

<Encapsulation Process of Perovskite Photovoltaic Devices Using Self-Healing Polymers>A stretchable encapsulation film and electrode materials made of self-healing polymer were introduced to perovskite photovoltaic devices instead of glass, enhancing the device's stretchability, flexibility, and operational stability without additional processes. In particular, even when the self-healing polymer was damaged by external impact, it prevented the leakage of lead compounds constituting the perovskite.

Meanwhile, by utilizing the self-bonding property of the self-healing polymer material, the photovoltaic device modules can be assembled like stacking Lego blocks without soldering, allowing configuration according to user demand. Additionally, the polymer material used can be easily peeled off, enabling the recycling of expensive ITO substrates, which is another advantage.

/Illustration provided and explained by Dr. Insoo Kim of Korea Institute of Science and Technology and Kyung Hee University, and Professor Donghee Son of Sungkyunkwan University

[Asia Economy Reporter Kim Bong-su] A self-healing polymer material has been developed that preserves the flexibility characteristic of perovskite, a next-generation solar cell material, while preventing the critical drawback of lead contamination.

On the 27th, the National Research Foundation of Korea announced that a joint research team led by Dr. Kim In-su of the Korea Institute of Science and Technology (KIST) and Professor Son Dong-hee of Sungkyunkwan University developed a fabrication technology for stretchable and flexible perovskite solar cells to prevent lead leakage. Perovskite materials are flexible, capable of bending and stretching, and can achieve high efficiency at low cost, making them a focus of research as next-generation solar cell materials. However, the lead component in perovskite can dissolve in water and leak externally, which has been a problem. Previously, glass coatings were used to block heat and moisture, but glass is fragile and lacks stretchability, failing to preserve the inherent flexibility of perovskite materials. This made their use in wearable devices difficult.

The research team developed a technology that prevents lead leakage from perovskite, which is vulnerable to heat and moisture, by using a lightweight and flexible self-healing material instead of rigid glass. The technology allows bending and stretching, and even if the material is torn by external impact, self-healing blocks lead leakage. By applying a PDMS-based self-healing polymer that recovers damaged parts through hydrogen bonding as an encapsulation film and electrode material, they succeeded in achieving both lead compound leakage prevention and stretchability without additional processing.

The team expects this to contribute to accelerating the commercialization of perovskite-based optoelectronic devices and serve as a stepping stone for expanding application fields. In an experiment simulating hail impact on perovskite solar cells encapsulated with the self-healing polymer, the amount of lead compounds leaked into water was measured at about 0.6 ppb, confirming a lead leakage prevention effect approximately 5,000 times higher than the conventional glass encapsulation technology at about 5.6 ppm. Additionally, by utilizing the self-healing polymer’s ability to self-adhere, users can stack desired optoelectronic device modules like building blocks without soldering processes, enabling applications in personal portable devices and body-attached devices. The research team is conducting follow-up studies to improve the durability of the self-healing polymer, which is permeable to water and vulnerable to heat, to ensure the durability of perovskite-based optoelectronic devices even in hot and humid environments.

This research was published on the 29th of last month in the international journal on nanomaterials, ACS Nano.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)