Joint Research by KAIST and KRICT Develops Advanced Printing Technology

Published in Science Advances, Patent Filed

Nature-Inspired Structural Color Custom Printing Technology

[Asia Economy Reporter Kim Bong-su] The feather patterns of peacocks, the iridescent colors of mother-of-pearl lacquerware, and the changing hues of chameleons have long been impossible for humans to replicate. The colors change depending on the angle and elasticity, making it impossible to artificially reproduce the iridescent and sparkling color effects. However, domestic researchers have developed cutting-edge printing technology that can print such 'structural colors' exactly as they appear in nature.

The Korea Advanced Institute of Science and Technology (KAIST) announced on the 14th that Professor Kim Shin-hyun's research team from the Department of Biological and Chemical Engineering, in collaboration with Dr. Lee Soo-yeon’s research team from the Korea Research Institute of Chemical Technology, has developed a technology to custom-print nature-inspired structural colors and filed a patent for it. This technology was documented in a paper published on the 24th of last month in the international journal Science Advances.

Structural color is a type of color that appears due to the structure of an object rather than pigments, distinguishing it from colors produced by conventional chemical dyes. Structural colors have an iridescent and sparkling appearance and can be observed in nature on the feathers of male peacocks, the skin of chameleons, and the wings of Morpho butterflies. Notably, our ancestors valued natural structural colors and used abalone shells in mother-of-pearl lacquerware crafts, and decorations showing structural colors have been found on jewel beetles in artifacts from the Silla period.

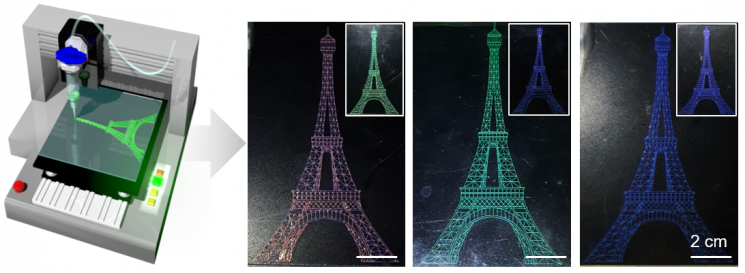

The structural color printing technology developed by the research team uses the three-dimensional crystal structure of colloidal particles instead of chemical pigments to produce color. Through a customizable printing process, it is expected to be applicable in a wide range of fields including optical devices, optical sensors, and anti-counterfeiting materials.

The method to artificially form structural colors involved creating three-dimensional crystal structures from colloidal nanoparticles. However, crystallization of colloids generally requires stringent process conditions and long processing times, posing limitations. Moreover, shaping colloidal crystals to exhibit desired structures and patterns required complex manufacturing processes, making practical application nearly impossible.

The research team developed a new technology that enables patterning of colloidal crystals through a newly formed colloidal ink printing process. This allowed the formation and patterning of precise colloidal crystal structures through a simple printing process. In particular, the printing process enabled free customization of graphic design, color brightness and saturation, mechanical properties, and angle dependency.

The core of the technology lies in the optimization of the colloidal ink. The research team designed the ink to control its physical properties suitable for printing while enabling spontaneous formation of colloidal crystals to exhibit excellent optical characteristics. This allowed printing lines, the basic components of graphics, at a high resolution comparable to the thickness of human hair at speeds up to 15 mm/s, and achieving reflectance as high as 90% on surfaces.

Especially, while conventional structural color patterning methods require very complex processes to form multicolor patterns, the research team designed the ink so that different inks used simultaneously do not mix, enabling easy production of multicolor patterns.

The newly developed printing method can print not only on non-absorbent substrates such as glass, metal, and plastic but also on fabrics and paper. The printed structural color patterns change color depending on the viewing angle and can be adjusted to change color when stretched or bent, similar to a chameleon.

Professor Kim said, "The newly developed structural color-based color printing technology could become a new tool for the MZ generation to express their individuality."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)