Joint Venture Plant Construction in North America

Phase 1: 30,000 Tons Construction... Planned Gradual Expansion

High-Nickel Mass Production Scheduled from 2024

[Asia Economy Reporter Hwang Yoon-joo] Posco Chemical, responsible for Posco Group's secondary battery materials business, is partnering with General Motors (GM), the No. 1 automaker in the United States, to launch a cathode material joint venture. This is the world's first case of a battery materials company forming a joint venture with an automaker.

Posco Chemical and GM jointly announced the establishment of a cathode material joint venture to build a large-scale production plant in the North American region. The joint venture ratio and location are currently being negotiated. The joint venture company plans to start producing high-nickel cathode materials from 2024. The produced cathode materials will be supplied to Ultium Cells, GM's electric vehicle battery manufacturer.

Cathode material plants are generally constructed in units of 30,000 tons. The joint venture with GM is also expected to start with a 30,000-ton scale in the first phase and gradually expand in stages.

Posco Chemical is the first battery materials company to establish a joint venture with an automaker, building a supply chain for key battery materials in North America, where the electric vehicle market is rapidly growing. Cathode materials account for about 40% of the battery cost.

Selected as a cathode material supplier for Ultium Cells in December 2020, Posco Chemical is constructing a plant with an annual capacity of 60,000 tons in Gwangyang. The newly established North American plant will additionally supply large-scale cathode materials, expanding cooperation with GM.

GM established Ultium Cells with LG Energy Solution in 2019 and is building battery cell production plants with an annual capacity of 35 GWh each in Ohio and Tennessee. GM has also announced plans to build two additional battery cell plants by the mid-2020s.

The joint venture between the two companies is a strategic decision made amid the U.S. government's strong push for eco-friendly mobility policies to replace 50% of new car sales in the U.S. with electric vehicles by 2030 and tariff policies to strengthen the domestic battery supply chain. It is expected to secure leadership in the electric vehicle industry in the North American market proactively.

Posco Chemical has entered the North American market stably by partnering with a global automaker, minimizing risks associated with large-scale overseas investments. Using this joint investment as a stepping stone, Posco Chemical plans to continue expanding global cathode material production capacity in North America, Europe, and China.

Posco Chemical became a joint venture partner with GM due to its close cooperation as a supplier of both cathode and anode materials, the two major battery materials, to Ultium Cells, gaining recognition for its material technology, quality, and mass production capabilities. Posco Chemical plans to supply high-nickel NCMA cathode materials, a next-generation electric vehicle material, and low-expansion anode materials that shorten battery charging time and improve stability when Ultium Cells begins production.

Additionally, Posco Group's stable procurement of raw materials such as lithium, nickel, and graphite has served as a differentiated competitive advantage. Posco is pursuing production of 220,000 tons of lithium and 100,000 tons of nickel by 2030 and has solidly built the entire battery materials value chain through acquiring shares in a graphite mine in Tanzania and constructing a battery recycling plant.

Posco Chemical is establishing global battery material mass production bases in Korea and the world's three major automobile markets: the United States, China, and Europe, and is diversifying its customers through close cooperation with major automakers and battery companies.

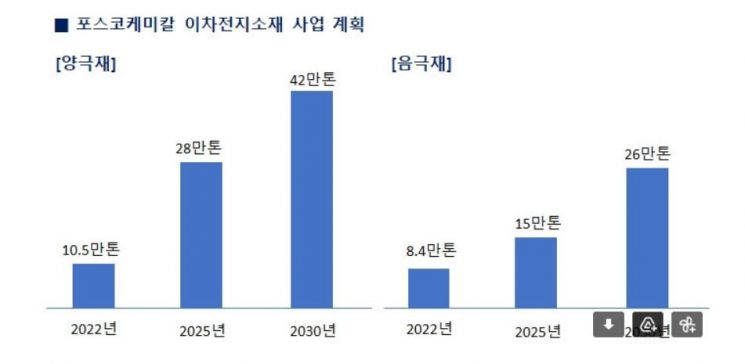

In August this year, Posco Chemical decided to invest in building a 30,000-ton scale cathode material and precursor production plant in China, and starting with this North American investment, it plans to promote the construction of production plants in Europe as well. Posco Chemical plans to expand its annual cathode material production capacity from 105,000 tons in 2022 to 280,000 tons in 2025 and 420,000 tons by 2030.

Doug Parks, GM Vice President of Global Product Development and Purchasing, said, "Our collaboration with Posco Chemical is a core part of our strategy to rapidly expand electric vehicle production in the U.S. and drive innovation in battery performance, quality, and cost," adding, "GM is building a sustainable and resilient North American electric vehicle supply chain ecosystem that covers everything from raw materials to battery cell manufacturing and recycling."

Min Kyung-jun, CEO of Posco Chemical, said, "We are pleased to participate in the global battery supply chain construction project by cooperating with GM, which leads the global electric vehicle industry," and added, "Based on Posco Group's world-class material technology, mass production capabilities, and raw material competitiveness, we will innovate key battery materials and lead the growth of the global eco-friendly mobility market together with GM."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.