KBSI Opens Path for Vanadium Dioxide Processing and Commercialization

Discovers It Melts at 66°C When Compressive Stress Is Uniform Without Impurities

[Asia Economy Reporter Kim Bong-su] Domestic researchers have paved the way for the commercialization of vanadium dioxide, a smart window material attracting attention for realizing 'zero-energy buildings.' Using a synchrotron radiation accelerator, known as a 'giant microscope,' they confirmed that in a homogeneous nanocrystal state, vanadium dioxide can melt at 66 degrees Celsius without mixing impurities.

The Korea Basic Science Institute (KBSI) announced on the 17th that it succeeded in real-time observation of microstructural changes inside vanadium dioxide nanocrystals with ultra-high resolution, revealing the impact of internal stress states on the abrupt phase transition characteristics between metal and insulator. This was a joint effort by Dr. Hong Woong-ki’s research equipment development team, Professor Son Jeong-in’s team at Dongguk University, and Dr. Lee Soo-yong’s team at the Pohang Accelerator Laboratory (PAL).

The study confirmed that the phase transition temperature and crystal phase of vanadium dioxide can be controlled solely by uniform internal stress regulation of nanocrystals, without impurity doping. For the first time, using a synchrotron radiation accelerator, a correlation between internal stress states, subtle crystal structures, and rapid electrical and optical property changes was revealed.

Vanadium dioxide is a material whose electrical properties change from an insulator to a metal depending on external conditions, simultaneously switching optically between transmitting and blocking infrared rays. It is gaining attention as a next-generation core material for ultra-fast switching devices, high-performance sensors, memory devices, and thermochromic smart windows that adjust infrared transmittance according to temperature to reduce building heating and cooling energy.

Vanadium dioxide, produced as thin films or nanocrystals on substrates such as silicon, alumina, or glass, changes properties with external condition variations and has been limited in industrial use due to difficulties in property control. The key is to clarify the correlation between crystal structure changes caused by internal stress and phase transition properties and to be able to control that stress.

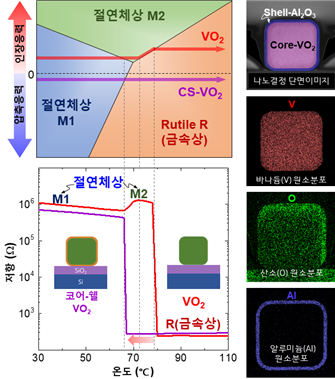

The research team created a core-shell structure by thinly coating amorphous alumina (Al2O3) on the surface of vanadium dioxide nanocrystals to uniformly maintain compressive stress inside the material. Microstructural changes inside the nanocrystals were observed using a third-generation circular synchrotron radiation accelerator X-ray device (Pohang Accelerator PLS-II 9C beamline) with a beam size of micrometers (1 μm equals one-millionth of a meter). The accelerator X-rays used are one million times brighter than typical laboratory X-rays and can observe fine structural changes over 100 times more precisely.

Through this joint research, unlike previous experiments where vanadium dioxide showed partial phase transitions and unstable crystal phases at 80?120 degrees Celsius, vanadium dioxide with uniformly applied compressive stress in a core-shell structure exhibited a rapid phase transition near 66 degrees Celsius close to room temperature without mixed crystal phases.

The research results were published online on the 6th in the international materials science journal 'Applied Materials Today.'

Dr. Hong Woong-ki stated, “This research elucidates the nanoscale scientific phenomena of phase-change material property control, which is used in various applications such as high-speed switching electronic devices, high-performance sensors, and thermochromic smart windows for carbon neutrality, through synchrotron radiation accelerators.” He added, “We plan to expand follow-up research into advanced analytical devices and new material development fields using synchrotron radiation accelerators.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)