Samsung Electronics Foundry Forum 2021 Held

Announces Plans for 3nm GAA Mass Production in Early Next Year, Defying Industry Expectations

Several Months Ahead of TSMC in 3nm, Over a Year Ahead in GAA Adoption

Considering Securing Legacy Process Sites... Concurrent Development and Investment

[Asia Economy Reporter Su-yeon Woo] Samsung Electronics, aiming to become the number one system semiconductor company by 2030, has unveiled its GAA (Gate All Around)-based fine process roadmap, closely pursuing Taiwan's TSMC, the world's leading foundry company. Samsung's strategy is to lead the market and rise to the top through an unparalleled technological gap by securing the world's first title in all aspects of technology, including fine processes and transistor structures.

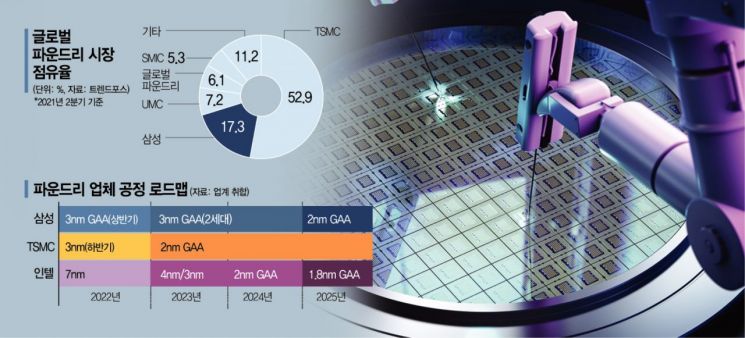

On the 7th, Samsung Electronics held the 'Samsung Foundry Forum 2021' online, showcasing next-generation foundry fine process technology. At this event, Choi Si-young, President of Samsung Electronics Foundry Business Division, announced plans to introduce GAA technology in the 3nm process starting in the first half of next year, begin mass production of the 3nm second generation in 2023, and start 2nm process mass production in 2025.

According to the roadmap, Samsung will surpass TSMC not only in the 3nm fine process competition but also in transistor technology (GAA). Initially, the industry expected TSMC to start mass production of the 3nm process in the second half of next year, claiming the world's first title, while Samsung was expected to respond by introducing GAA technology for the first time in the second half of next year.

However, Samsung broke industry expectations by advancing both the 3nm process and GAA introduction to the first half of next year. Although TSMC currently leads in market share in the foundry market, this move reflects Samsung's determination not to concede its dominant position in terms of technological capability. TSMC plans to start mass production of the 3nm process in the second half of next year and introduce GAA technology from the 2nm process as early as 2023. Based on the 3nm process, Samsung is ahead by several months, and in terms of GAA technology introduction, by more than a year.

GAA is an essential technology for continuing process miniaturization in terms of power efficiency, performance, and design flexibility. Samsung's proprietary GAA technology, the 'MBCFET' structure, applied to the 3nm process, is expected to improve performance by 30%, reduce power consumption by 50%, and decrease area by 35% compared to the existing FinFET-based 5nm process.

Samsung's world-first GAA-based 3nm process is expected to be introduced primarily at the Pyeongtaek plant, which is currently expanding. There are also prospects that the advanced 3nm line will be installed at the new foundry plant in the United States, where the final site selection is underway. President Choi said, "We are currently adding new space at Pyeongtaek to produce products with processes below 4nm," and added, "Regarding the U.S. plant, where several candidate sites are being reviewed, we will announce an official position soon."

Meanwhile, Samsung is simultaneously investing in and developing legacy processes to secure profitability, in addition to acquiring advanced process technology. On this day, President Choi announced the development of a new 17nm FinFET-based process and also mentioned considering options for securing new factory sites for legacy processes.

Recently, applications using legacy processes of 28nm and above, such as image sensors and mobile display driver ICs, have been diversifying. Samsung's newly introduced 17nm process is expected to improve performance by 38%, power efficiency by 49%, and reduce area by 43% compared to the existing 28nm process. President Choi stated, "We will expand production capacity through large-scale investment and continue technological innovation not only in advanced processes like GAA but also in existing processes," adding, "We will provide differentiated value so that customers' diverse ideas can be realized in chips."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)