Institute for Basic Science Develops Lightweight, Flexible Straw-Type Fuel Cell

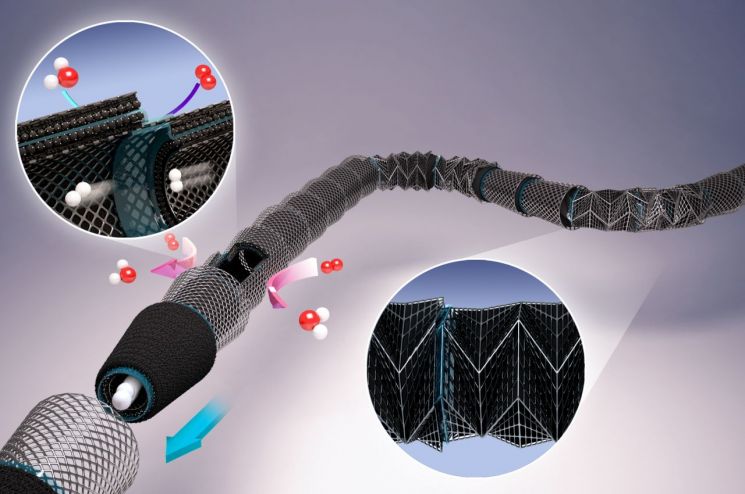

Schematic diagram of a lightweight and bendable straw-shaped fuel cell developed by the Institute for Basic Science.

Schematic diagram of a lightweight and bendable straw-shaped fuel cell developed by the Institute for Basic Science.

[Asia Economy Reporter Kim Bong-su] A new fuel cell optimized for small electronic devices such as drones, smartphones, wearable devices, and various mobile gadgets has been developed.

The Institute for Basic Science (IBS) announced on the 8th that the research team led by Sung Young-eun, Deputy Director of the Nanoparticle Research Division and Professor of Chemical and Biological Engineering at Seoul National University, in collaboration with Professor Jo Yong-hoon’s team at Kangwon National University, developed a lightweight and flexible straw-shaped fuel cell. It is evaluated as presenting a new direction for fuel cell development by being simpler, lighter, and capable of being configured into various shapes compared to existing models.

Fuel cells are mainly composed of end plates on both sides, a separator, and a membrane electrode assembly (MEA). The end plates uniformly apply pressure to the MEA. The separator prevents hydrogen and oxygen from mixing while serving as a pathway for reactants. The end plates and separator account for about 80% of the total weight, and until now, there have been limitations in reducing their weight.

The research team devised a method to lighten the fuel cell by minimizing the roles of the heavy end plates and separator. They designed a pleated straw-shaped fuel cell by connecting conical units stacked like paper cups. Even after removing the end plates used for fixing parts and maintaining structure, the shape was maintained. They also confirmed that the inside of the tube could be used as a fuel (hydrogen) channel and the outside as an air (oxygen) supply surface, effectively replacing the role of the separator. Using this method, the weight of components excluding the MEA was reduced by more than 60%.

Like the pleated part of a straw, it can be freely shortened or extended. Folding along the designed origami pleats can reduce the volume by 50%, and it can flexibly bend up to 90 degrees. There is almost no performance degradation when folded or bent. Another advantage is the simple series connection, stacking like paper cups. This means it is easy to produce fuel cells with desired voltage and current, as well as operate at high voltage. The weight of a fuel cell with two units connected in series is about 0.22g, and the volume is approximately 0.565㎤, making it very small and light. Nevertheless, it can generate 198mW of power and a specific power density of 897.7 W·kg-1. Additionally, it maintained the same performance after more than 100 current-voltage curve measurements.

Although this study developed a polymer electrolyte membrane fuel cell (PEMFC), it can also be applied to various other electrochemical devices, such as hydrogen production equipment like water electrolysis.

Fuel cells using hydrogen produce electricity through the electrochemical reaction of hydrogen (H2) and oxygen (O2) in the air. Since the reaction only produces electrical energy and water, it is recognized as an eco-friendly future energy source that does not emit pollutants. Fuel cells have particularly high energy density. Therefore, they are useful not only in places requiring large amounts of energy such as power plants and hydrogen vehicles but also in portable small electronic devices like smartphones and drones.

Deputy Director Sung said, “We developed a lightweight and flexible three-dimensional straw-shaped fuel cell by applying the principle of origami to fuel cells,” adding, “We expect remarkable progress in the fuel cell field through the introduction of this innovative design.”

The research results were published online on the 19th of last month in 'ACS Energy Letters' (IF 23.101), an energy field journal published by the American Chemical Society (ACS).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)