Professor Lee Jong-seok's Research Team at Sogang University "Distinguishes Gas Molecules Smaller than 1/500th the Thickness of a Hair"

Separates Propane and Propylene with Similar Boiling Points, Reducing Energy Input to One-Tenth

[Asia Economy Reporter Kim Bong-su] A membrane capable of separating gas molecules with an extremely fine difference in size of 1/5 millionth the thickness of a human hair (less than 0.02 nm) has been developed by a domestic research team. This technology reduces energy costs to one-tenth when separating polymer materials with very similar sizes and boiling points, such as propane and propylene.

The National Research Foundation of Korea announced on the 7th that Professor Lee Jong-seok's research team at Sogang University developed a porous metal-organic framework-based separation membrane that can separate propylene (C3H6) and propane (C3H8) gas molecules from each other.

A metal-organic framework refers to a porous material composed of coordination bonds between metal ions and organic ligands. The material used in this study is ZIF-8 (zeolitic imidazolate framework-8). It has a large surface area and pore volume and can incorporate various functional structures, making it widely used in adsorbents and other applications.

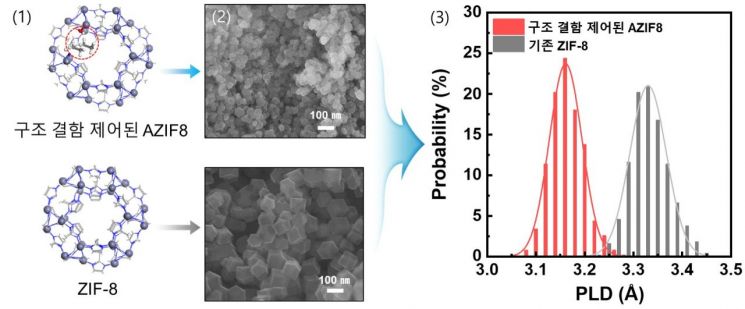

The research team utilized the principle where nanoparticles with ultrafine pores inside act as a sieve to selectively allow or block gas molecules. They developed a new synthesis method that easily and precisely controls the size of ultrafine pores in crystalline nanoparticles made of metal-organic frameworks using an amine modulator. Through this, they succeeded in obtaining a separation membrane with high permeability and selectivity, allowing smaller propylene molecules to pass well while blocking slightly larger propane molecules, achieving top-level separation performance. The amine modulator bonded with zinc induced repulsion due to electron distribution imbalance, preventing nanoparticle aggregation and increasing affinity with the polymer.

ZIF-8 particles synthesized with a uniform size (60 nm) strengthened the framework and enhanced the sieving function. Particularly, even at high particle content (>40 wt%) within commercial polymers, excellent dispersibility and affinity were demonstrated. The research team expects that this membrane fabrication method can be applied to the separation of various gases such as ethylene and ethane, carbon dioxide and carbon monoxide, and carbon dioxide and methane. Notably, ethylene, known as the "rice of industry" as a raw material for plastics and synthetic fibers, is also obtained by separating it from ethane, and the size difference between these two is similar to that between propylene and propane. The research team plans to continue research on coating the membrane onto porous supports and scaling up the membrane area.

This research was supported by the Mid-career Research Program and the C1 Refinery Project promoted by the Ministry of Science and ICT and the National Research Foundation of Korea. It was published on the 26th of last month in the international journal in the field of materials physics, Advanced Functional Materials.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)