5 Trillion Investment by 2025

Expansion of Recycling Technology and Facilities

Brand New Day Briefing Today

Expressing Determination to Seize Market Leadership

[Asia Economy Reporter Choi Dae-yeol] SK General Chemical has decided to invest 5 trillion KRW by 2025 to expand technologies and facilities for recycling used plastics and to grow its eco-friendly materials business. In the mid to long term, the company plans to recycle all the plastics it produces and take the lead in the global plastic recycling market, which is expected to grow significantly in the future. The company will also change its name to SK Geocentric, reflecting the meaning of "putting the Earth at the center."

On the 31st, SK General Chemical President Na Kyung-soo and key executives announced these plans at the Brand New Day briefing. Until now, the company’s main business was producing plastic materials and raw materials from petroleum by-products, but it aims to completely transform into an environmental company centered on plastic recycling and realize ESG (Environmental, Social, and Governance) management.

SK General Chemical introduced a circular economy business model based on urban oil fields. This method produces fuel or new plastic materials by utilizing waste plastics even when oil is not available. To make plastics, basic chemical products such as ethylene and propylene, which are derived by cracking naphtha obtained from refining crude oil, are required.

Although the use of plastics will not decrease in the future, due to climate change and other reasons, the supply of crude oil is expected to become more difficult, increasing the need to produce plastics in new ways. President Na said, "We will grow into the world's largest urban oil field company that recycles waste plastics made from petroleum and extracts oil again."

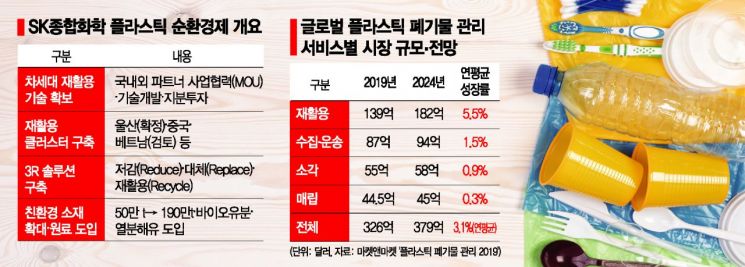

The company plans to first secure the capacity to process as much waste plastic as the amount of plastic produced domestically (900,000 tons per year). To this end, it finalized plans last month to build a pyrolysis and plastic recycling plant in the Ulsan Mipo Industrial Complex. The recycling cluster is being considered not only in other domestic regions but also overseas in countries such as China and Vietnam. To secure recycling technology, the company will cooperate with domestic and international firms and pursue various approaches including joint ventures (JV) and equity investments. Furthermore, by 2027, it aims to directly and indirectly recycle the amount of plastic produced (2.5 million tons per year), including overseas operations. This corresponds to about 20% of the waste plastics flowing into the oceans worldwide.

Company Name Change to SK Geocentric

Realizing ESG Management Centered on Eco-Friendliness

The company will also increase its eco-friendly materials business, which currently accounts for less than 20% of its revenue. Vehicle materials will be made lighter, and packaging materials will be developed to use as little plastic as possible. The investment over the next five years will be used to secure domestic and international facilities and plants and to develop technology. The production capacity of eco-friendly materials will increase from the current 500,000 tons per year to 1.9 million tons by 2025. The company will also use eco-friendly fuels such as bio-oil and pyrolysis oil.

President Na said, "The recycled plastics market is expected to grow at a rate of about 12% until 2030, becoming a 600 trillion KRW market by 2050. By 2025, we will generate 600 billion KRW in EBITDA (earnings before interest, taxes, depreciation, and amortization) from recycling and eco-friendly sectors, transforming financially into a perfect ‘green company’ beyond our existing business."

SK General Chemical originated from Korea Petroleum Corporation (Yukong), the first domestic refinery established in 1962, and was the first in Korea to introduce a naphtha cracking center (NCC) in 1972. The company has steadily shifted toward eco-friendly businesses, including suspending its NCC facilities domestically for the first time last year. The petrochemical industry is a large-scale plant industry where major domestic and international companies have traditionally enhanced competitiveness by expanding scale, so preparing an entirely new business is rare. SK General Chemical is the only domestic company to have reduced its ethylene production capacity, a representative petrochemical product.

The new company name will be used starting next month on the 1st. It combines "geo," meaning Earth or soil, and "centric," meaning centered. SK Group Chairman Chey Tae-won has emphasized the need for companies to actively utilize their technology, capital, and capabilities to solve environmental issues such as climate change. President Na said, "The issue of waste plastics is best solved by chemical companies that understand it most. We will lead the circular economy of waste plastics and the spread of eco-friendliness based on ESG management."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.