KIST Develops Technology to Minimize Initial Lithium Loss in Graphite-Silicon Composite Electrodes with Larger Storage Capacity

Can Increase Capacity and Lifespan of Lithium Batteries for Electric Vehicles and Smartphones

[Asia Economy Reporter Kim Bong-su] Lithium batteries used in electric vehicles and smartphones lose 10-30% of their storage capacity during the initial charge, but a battery manufacturing process that can prevent this loss has been developed by domestic researchers. This technology is evaluated as one that can significantly increase the usable battery capacity, thereby dramatically extending the driving range of electric vehicles and the usage time of smartphones.

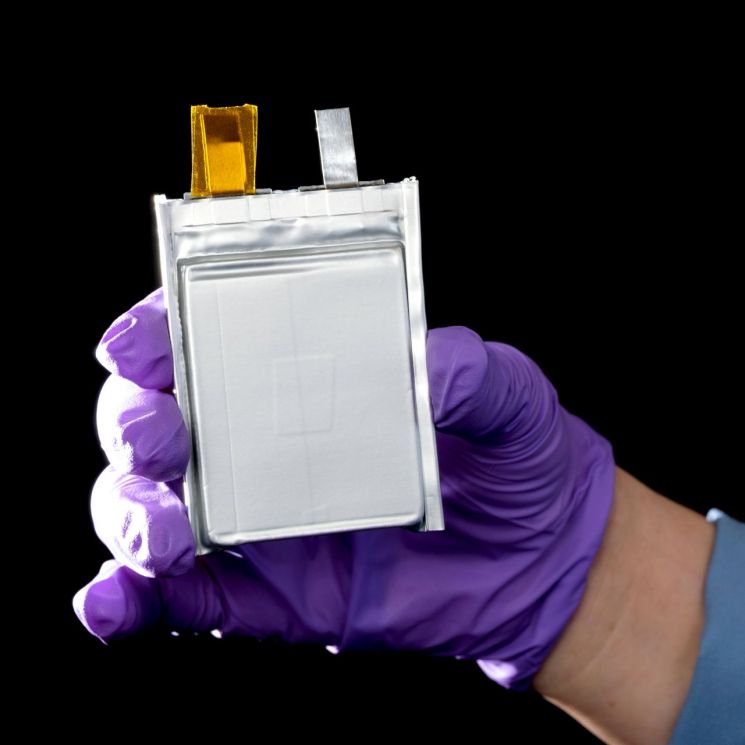

The Korea Institute of Science and Technology (KIST) announced on the 16th that a joint research team led by Dr. Lee Mina of the Energy Storage Research Center developed a graphite-silicon composite anode pretreatment solution that minimizes storage capacity loss during the initial charge of lithium batteries. Through this, the silicon content, which has a larger energy storage capacity, can be increased to over 50%, enabling the production of anode materials with more than 2.6 times the capacity compared to existing ones, the research team stated.

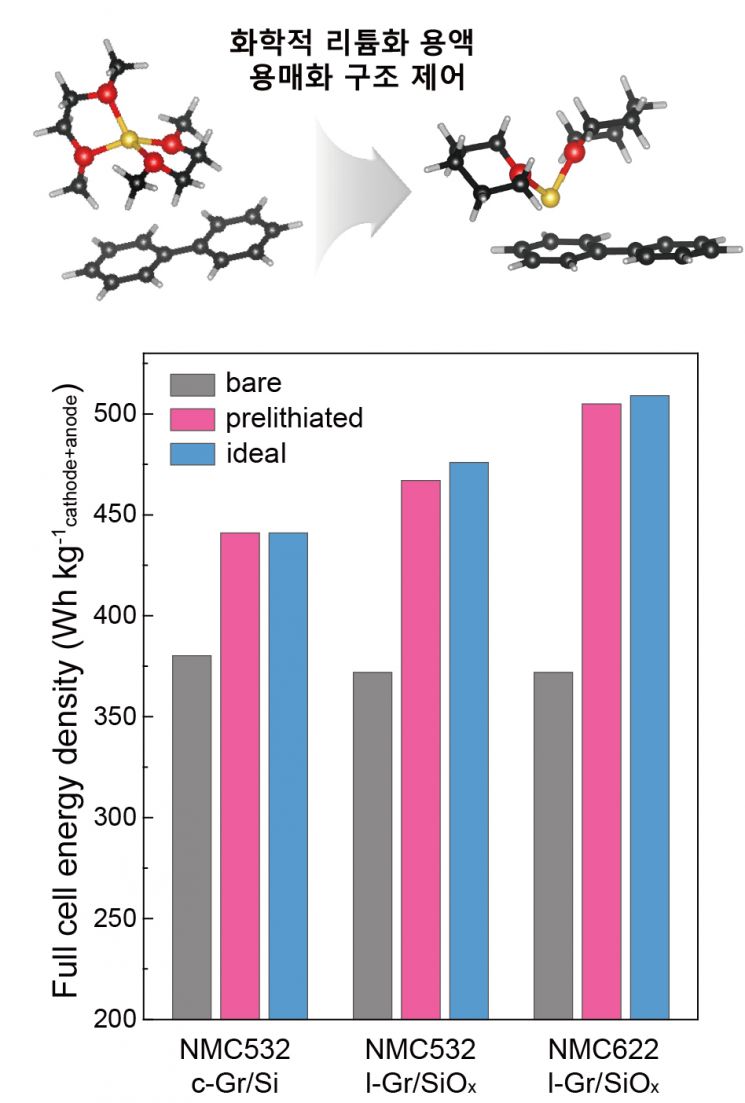

Most commercial lithium batteries use graphite as the anode material, but graphite-silicon composite electrodes are attracting attention as next-generation anode materials to increase energy storage capacity. The problem is that silicon consumes about three times more lithium than graphite during the initial charge. The higher the silicon content, the greater the overall battery capacity, but this also increases the initial loss, creating a dilemma. For example, when the silicon content is 50%, 40% of the total lithium is lost initially. Therefore, currently, the silicon content cannot be increased beyond 15%.

The research team developed a special solution that supplies additional lithium to the graphite-silicon composite electrode to compensate for the lithium that would be lost. They utilized a solution previously developed to block the initial lithium consumption of silicon electrodes. By adjusting the strength of molecular interactions within the solution, they created a new solution that can be applied to graphite-silicon composite electrodes to supply additional lithium and block initial lithium consumption.

When the graphite-silicon electrode is immersed in this solution for about one minute, even with a silicon ratio increased to 50%, the initial lithium consumption phenomenon is completely blocked, showing a high initial efficiency close to 100%, with less than 1% lithium consumed during the first charge. The developed electrode has about 2.6 times higher capacity compared to anodes using only graphite and maintains 87.3% of its capacity after 250 charge-discharge cycles, demonstrating excellent durability.

Dr. Lee Mina of KIST said, “Through this research, it is expected that the silicon content in graphite-silicon composite anodes, which previously remained within 15%, can be increased to over 50%, enabling the production of batteries with higher capacity,” adding, “This can be utilized to dramatically improve the driving range of electric vehicles in the future.”

The research results were published in the latest issue of the international chemistry journal, Journal of the American Chemical Society (IF: 15.419, JCR top 6.621%).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)