DGIST Professor Sanggaraju Shanmu's Team Mixes Carbon Nanofibers into Existing Neupion

[Asia Economy Reporter Kim Bong-su] A new synthesis method has been developed that can significantly improve the performance and durability of fuel cells.

The Daegu Gyeongbuk Institute of Science and Technology (DGIST) announced on the 24th that a research team led by Professor Sangaraju Shanmugam from the Department of Energy Engineering succeeded in enhancing the performance and solving the degradation issues of the polymer electrolyte membrane (PEM) made of Nafion material used in fuel cells.

The newly developed PEM is expected to improve both the output and durability of fuel cells, which is anticipated to have a positive impact on various industrial fields where fuel cells are utilized in the future.

The "polymer electrolyte fuel cell" operates on the principle that hydrogen gas is split into hydrogen ions and electrons; the hydrogen ions move through the electrolyte membrane to the opposite electrode, while the electrons travel along a conductor to generate electrical energy. The membrane that allows only hydrogen ions to pass through is the polymer electrolyte membrane (PEM). Nafion, which has high ionic conductivity, is advantageous for manufacturing PEMs, but its performance and lifespan deteriorate as humidity decreases.

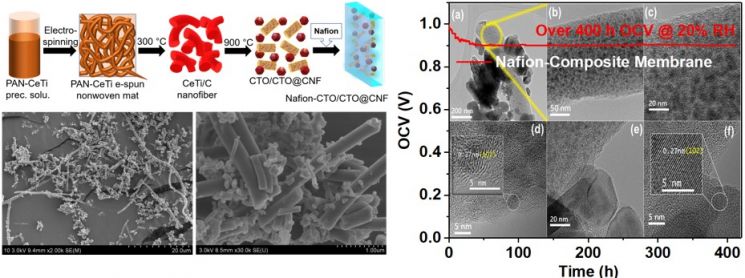

The research team conducted a study on methods to ensure stable performance and lifespan of PEMs made from Nafion even under low humidity conditions. As a result, by mixing a new material with the previously used Nafion, they were able to solve not only the existing drawbacks but also the performance and durability issues simultaneously. They developed a new PEM by mixing carbon nanofibers uniformly distributed with cerium-titanium oxide nanoparticles with Nafion. The mixed material prevented the degradation of the Nafion-based PEM used in fuel cells and enabled normal operation even in low humidity environments. Furthermore, it reduced the degradation level by half compared to the existing material, doubling the durability of Nafion, which previously lasted 200 hours at 80 degrees Celsius.

The research results were published online in the international journal "American Chemical Society".

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)