'Eunseong The John Philboard' with Semi-Noncombustible Performance Applied on All 6 Surfaces of Insulation Material

Excellent Fire Safety and Outstanding Insulation Performance

As the revised Building Act, which significantly strengthens fire safety standards for building finishing materials and insulation materials, is set to be enforced from the end of the year, an insulation specialist company in Gyeongsan, Gyeongbuk Province has attracted attention by developing EPS semi-noncombustible insulation materials that comply with the amended Building Act.

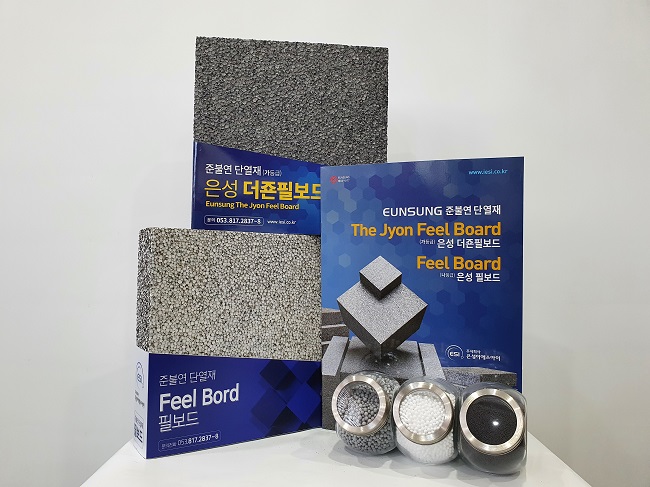

Eunseong SI Co., Ltd. (CEO Kang Seon-bae) has independently developed the Eunseong The Jyon Feel Board, an EPS semi-noncombustible insulation material that secures semi-noncombustible performance under the Building Act using a single material (core), making it highly fire-resistant.

Unlike composite products currently distributed in the market that attach fire-retardant sheets or apply flame-retardant liquids only on one side, Eunseong The Jyon Feel Board is a single EPS semi-noncombustible product that applies semi-noncombustible performance on all six surfaces of the insulation material, ensuring excellent fire safety while maintaining superior insulation performance.

Eunseong SI Co., Ltd. produces and sells semi-noncombustible insulation materials ‘Eunseong The Jyon Feel Board’ and ‘Eunseong Feel Board.’ By heating and expanding polystyrene, the raw material for insulation, into expanded polystyrene and applying a special flame-retardant coating technology to each particle, the insulation performance has been dramatically improved. At the same time, the semi-noncombustibility is maximized, making it an excellent semi-noncombustible building insulation material that prevents combustion and suppresses toxic gas generation in case of fire.

In particular, performance evaluation results show that the total heat release over 10 minutes was 4?6 MJ/㎡, and the maximum heat release rate did not exceed 200 kW/㎡ for more than 10 seconds. There were no harmful cracks, holes, or melting (fusion) penetrating the test specimen, and the gas toxicity test showed a behavior stop time of over 14 minutes, confirming stable semi-noncombustible performance.

Last June, the government announced in the ‘Fire Safety Measures for Construction Sites’ that sandwich panels containing styrofoam (EPS) and urethane foam insulation materials must secure semi-noncombustible or higher performance when used as finishing materials (including exterior wall insulation). It also stated that internal insulation materials such as urethane foam, which previously had no fire safety standards, must have flame-retardant performance.

The officially recognized test method to verify such flame-retardant and semi-noncombustible performance is the ‘Cone Calorimeter Method (KS F ISO 5660-1).’ It quantifies the heat and smoke generated when heat is applied to a test sample. The total heat release (8 MJ/㎡) and maximum heat release rate (200 kW/㎡) must not be exceeded. Flame-retardant performance requires securing about 5 minutes of evacuation time at 700℃, and semi-noncombustible performance requires about 10 minutes under the same conditions.

Eunseong The Jyon Feel Board not only has excellent semi-noncombustible performance but also satisfies innovative insulation performance with a thermal conductivity of 0.034?0.035 W/m·K.

Kang Seon-bae, CEO of Eunseong SI Co., Ltd., said, “We have been researching and developing semi-noncombustible insulation materials for many years. In 2017, we developed and produced the Eunseong Feel Board with a Class Na rating, and in 2020, we developed and have been producing and selling Eunseong The Jyon Feel Board, which improves insulation and performance compared to the Feel Board. Through continuous research and development, we are striving to produce upgraded products that solve the fire safety issues, which are the weak points of EPS insulation materials.”

He added, “Founded in 2000 as a specialized styrofoam production company, Eunseong SI Co., Ltd. is committed to improving quality and developing new products through systematic quality programs to enhance customer satisfaction. We are also dedicated to researching and developing safer and more environmentally friendly products considering eco-friendly building environments.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)