[Asia Economy Reporter Jeong Hyunjin] The global semiconductor shortage shows no signs of ending. Since last year, the surge in semiconductor demand has exacerbated an already tight supply situation, and natural disasters such as the cold wave in the United States and drought in Taiwan have further shaken the semiconductor industry. Recently, even water, a key element in semiconductor manufacturing processes, has become scarce, impacting factory operations at Samsung Electronics and Taiwan's TSMC.

According to major foreign media on the 27th, Samsung Electronics' semiconductor plant in Austin, USA, has been shut down since the 16th. The cold wave and heavy snowfall that hit Austin caused a power outage, halting factory operations, and this was followed by another setback due to water supply interruptions. Local rivers and water systems froze, leading to a water shortage, and it is expected to take some time to restore normal operations.

TSMC, the world's leading foundry company, is also facing difficulties in water supply due to the drought in Taiwan. Since the 23rd, water tank trucks have been deployed to supply industrial water necessary for semiconductor production at its main plants in northern Taiwan, including Hsinchu. A TSMC official told Japan's Nihon Keizai Shimbun, "We have started emergency measures considering the possibility of worsening water shortages." This is the first time in five years, since 2015, that TSMC has resorted to using water tank trucks for water supply.

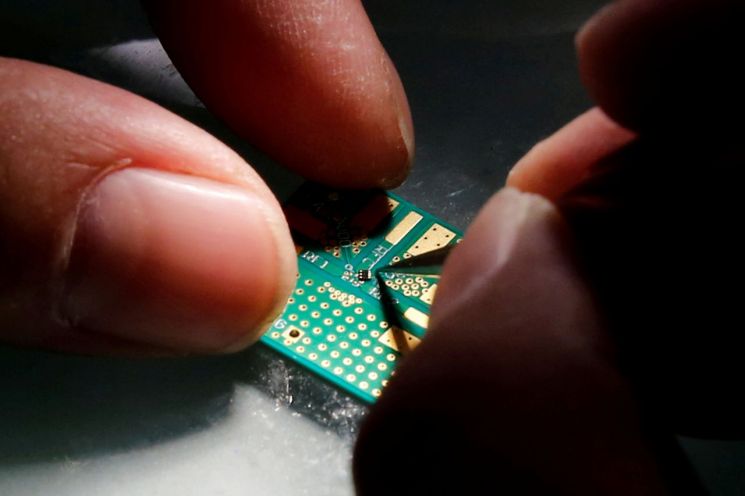

Water is an essential element in semiconductor manufacturing processes. According to industry sources, water is mainly used in numerous cleaning steps before and after semiconductor processes, such as washing away debris after wafer cutting and removing various chemicals. At this stage, highly purified water called "ultrapure water (UPW)"?which has had minerals, particulates, bacteria, microorganisms, and dissolved gases removed?is used.

The reason ultrapure water is used in semiconductor manufacturing is that semiconductors are highly sensitive to even the smallest dust particles, and any remaining tiny particle can cause errors. By using ultrapure water for cleaning, the industry explains that cleanliness is ensured, defects in semiconductors are minimized, and productivity is improved.

To achieve this, managing both the quality and quantity of water required for semiconductor processes is crucial. For example, TSMC's semiconductor plants in Taiwan use nearly 200,000 tons of water daily, necessitating strict control over both water quality and quantity. Therefore, semiconductor facilities are generally located where water supply is easily accessible. Additionally, semiconductor manufacturers manage water through wastewater treatment of effluents from processes and equipment, as well as recycling efforts to secure water efficiently.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)