Development of Multi-Anti-Counterfeiting Core Technology Including 3D Holograms

High-Precision, Automated Manufacturing Technology Enables Masterpiece Printing on Hair Thickness

[Asia Economy Reporter Junho Hwang] A technology to prevent counterfeiting has been developed by hiding counterfeit identification information inside conjugated polymer particles, which are conductive polymers similar to semiconductors. The research team that developed this technology expects it to become a core technology for next-generation anti-counterfeiting systems, as it fundamentally blocks counterfeiting.

Ulsan National Institute of Science and Technology (UNIST) announced that Professor Lee Ji-seok's research team developed a new manufacturing technology that hides multiple counterfeit identification information inside conjugated polymer particles, and their research results were published in Nature Materials on the 4th (local time).

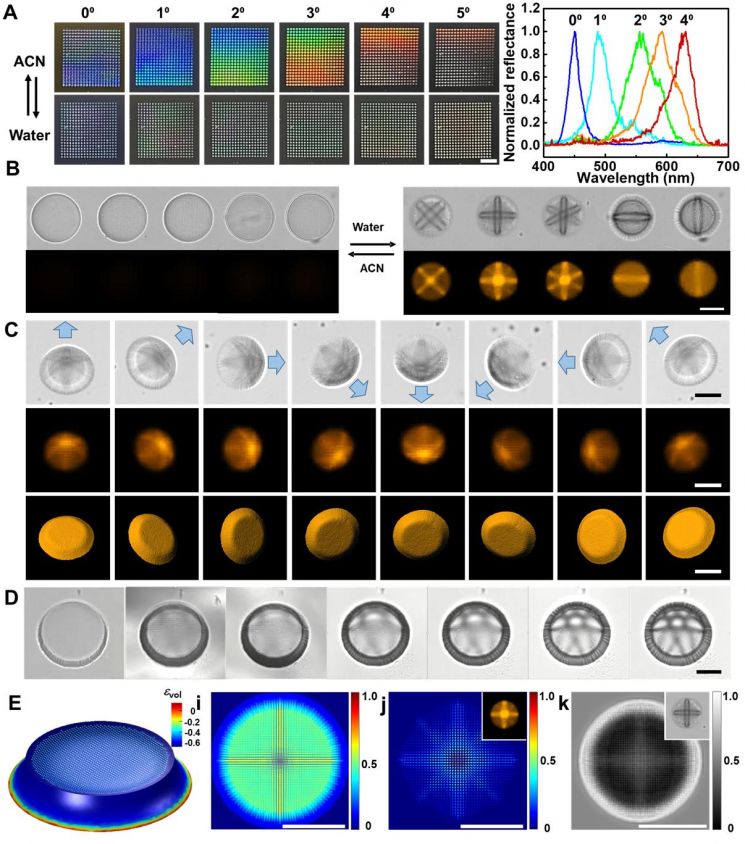

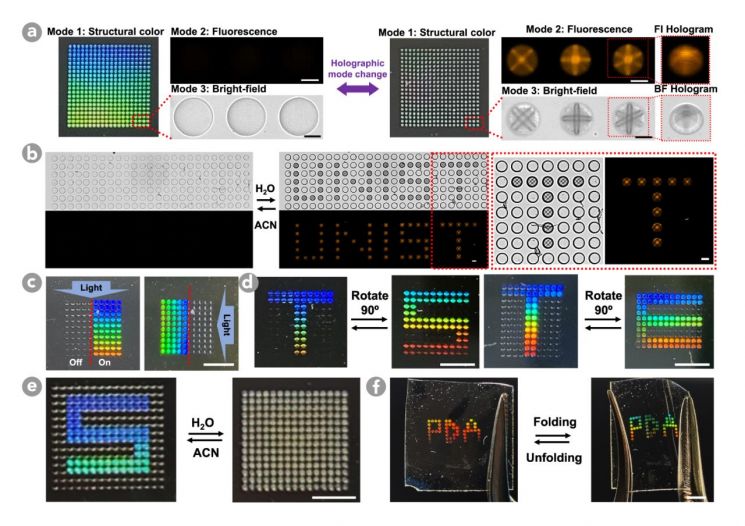

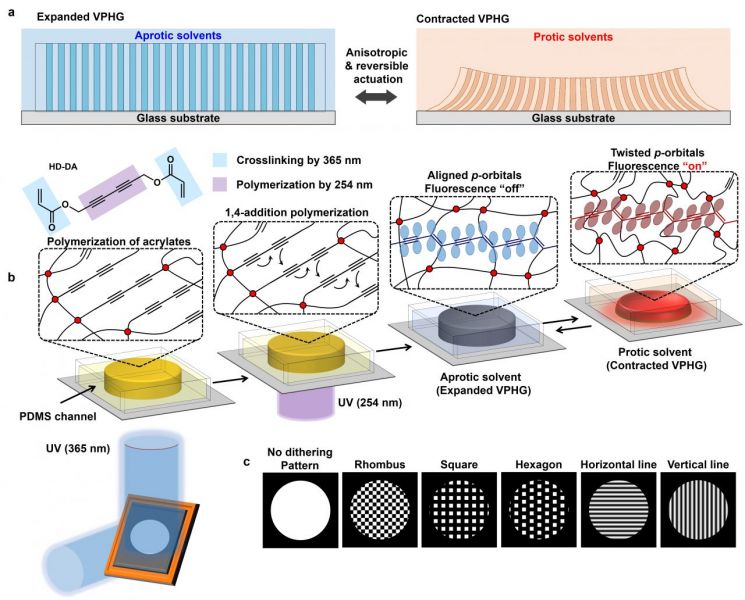

The research team developed a technology that implements security information such as 3D holograms, structural colors, and fluorescent properties in various forms and combinations on microparticles to make counterfeiting impossible. The conjugated polymer particles developed by the team have a characteristic (structural color) that changes color depending on the viewing angle. When these particles are immersed in water, the structural color disappears, revealing a 3D hologram (three-dimensional pattern) stored inside the particles. Additionally, when light is shone on the particles, a 3D hologram fluorescent pattern appears.

Professor Lee explained, "The 3D hologram implemented inside the particles (medium) is a true three-dimensional hologram with different shapes from every viewing angle, unlike conventional holograms that use optical illusions," and added, "This is the world's first implementation of a 3D hologram with full-parallax characteristics in a conjugated polymer medium."

The core of this technology is to pass light through 'mask filters' such as lattice or herringbone patterns to mask and locally control the amount of light applied to the photopolymerized conjugated polymer. Depending on the amount of light, the polymer's hardness and refractive index change three-dimensionally, producing structural colors and hologram patterns. The structural colors and hologram patterns are controlled by changing the type of mask.

For example, by applying this technology, an anti-counterfeiting device can be embedded in a 50,000 won bill that shows different characters depending on the viewing angle and disappears when immersed in water. Also, 3D holograms can be embedded inside the particles that act as 'pixels' of the characters, serving as another anti-counterfeiting device.

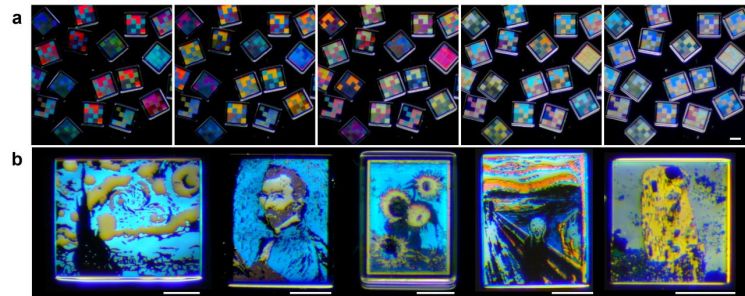

In particular, this anti-counterfeiting device is easily commercializable. Using the technology developed for manufacturing conjugated polymer particles, the research team also embedded high-resolution masterpieces inside particles as thin as a human hair. Although invisible to the naked eye, these masterpieces can be easily viewed with a commercially available magnifying glass. The team also succeeded in mass-producing microparticles that can act as taggants (anti-counterfeiting additives). These microparticles have a total of 16 grids arranged 4 by 4, and each grid can display 4 colors. By varying the color combinations expressed in each grid, one microparticle can generate approximately 4.16 billion (416) or more encryption codes.

A case applying high-precision automation technology used in the production of fine conjugated polymer particles

A case applying high-precision automation technology used in the production of fine conjugated polymer particles

Professor Lee stated, "Using this technology, it is possible to mass-produce anti-counterfeiting graphic stickers with high-resolution masterpieces printed inside particles as thin as a human hair, as well as taggants (anti-counterfeiting additives containing identification information)," and added, "This will be an innovative foundational technology in the security industry."

Jongwon Oh, a first author and doctoral researcher in the Department of Energy Chemical Engineering, explained, "The materials used in this study can easily produce particles that respond to external environments with optical signal changes, and thus can also be applied as metamaterials that actively control light."

Meanwhile, Professor Lee's team, along with graduate and undergraduate students, has founded a company called AMHOLO Co., Ltd., which develops anti-counterfeiting systems, accelerating the commercialization of this technology.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)