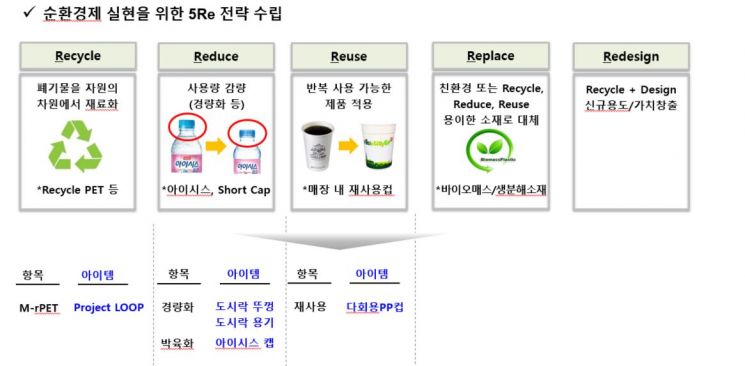

Lotte Chemical has established the '5Re' strategy, including reducing plastic usage, to realize a circular economy.

Lotte Chemical has established the '5Re' strategy, including reducing plastic usage, to realize a circular economy.

[Asia Economy Reporter Hwang Yoon-joo] An invisible change has occurred in the 'Icis' water bottles supplied by Lotte Chilsung. The sky-blue bottle caps have become smaller than before, and the labels have been redesigned to be peeled off in one go. Recently, Icis water bottles without any labels have also been released. This is not to increase profits. Lotte Chilsung directly requested Lotte Chemical to change the PET products in order to reduce plastic usage.

Globally, the chemical industry has already started competing to develop eco-friendly products. It is not just an environmental protection campaign; companies are producing chemical products using waste plastics as raw materials instead of petroleum or releasing biodegradable products one after another. The biggest focus of 'K 2019,' the world's largest plastics and rubber industry exhibition held last year, was also the 'circular economy.'

◆ EU to regulate single-use plastic products from next year... Market landscape is changing = The chemical industry's interest in plastic recycling stems from the changing market landscape. The global plastics market continues to grow, but institutional regulations and consumer demands are imposing restrictions on current production methods.

According to a report by the Korea Petroleum Association, demand for chemical products is expected to increase by about 30% by 2030 and 60% by 2050. Demand for petrochemical feedstock is rising significantly, especially in the Middle East and China, and the U.S. is also expected to see increased plastic demand by 2030. Europe’s share of petrochemical feedstock is projected to rise from the current 15% to 21% by 2050, and China’s share of crude oil for chemical feedstock is expected to surpass that for passenger cars (gasoline and diesel) by 2050.

Despite these demand forecasts, the chemical industry is focusing more on 'how to produce' rather than 'how to produce more.' This is because from next year, the European Union (EU) will ban the use of single-use items such as forks and knives in 10 categories. Additionally, by 2025, the use of plastic bags for food packaging must be reduced by 25% from current levels, and by 2030, all plastic packaging and bottles must use recyclable materials. This is why the chemical industry is focusing on 'plastic recycling.'

A chemical industry official said, "Just as the Volkswagen Group declared it would produce electric vehicles instead of internal combustion engine cars to comply with carbon dioxide regulations, the chemical industry has no choice but to increase the proportion of plastic recycling production due to plastic regulations."

Especially, apart from government regulations, consumer goods companies, which are major clients of the chemical industry, have independently declared plastic usage restrictions over the past few years. P&G, Starbucks, and Nike are representative examples. Starbucks banned plastic straws in stores worldwide, and Nike created guidelines for the use of polyvinyl chloride (PVC) in shoes. The design change of the 'Icis' PET water bottles produced by Lotte Chilsung is in the same context.

An official from a foreign chemical company said, "The largest customers are demanding a certain proportion of recycled plastic products or have announced they will not use specific products, turning this from a social contribution issue into a 'business problem.' This will affect not only the chemical industry but also many companies such as Taekwang Industrial, which supplies sneakers, in Korea."

◆ "If you don't secure the recycling market, you will be eliminated"... Chemical companies competing to develop eco-friendly products = The representative technology for 'plastic recycling' is PTC (Plastic-to-Chemical). It involves melting discarded plastics and reusing them as basic raw materials by chemically decomposing waste plastics to extract naphtha.

Although it has not yet reached a profitable stage, the chemical industry believes that raising the proportion of waste plastics used as raw materials to at least 30% is meaningful for profitability and solving waste problems.

As part of this, the global chemical company BASF started producing prototypes of mozzarella cheese packaging through the 'Chemcycling Project' last year. The project aims to recycle almost all plastics and produce products with high hygiene standards, such as food packaging. To this end, BASF invested 20 million euros (about 26.8 billion KRW) in Quantafuel, a Norwegian company specializing in pyrolysis of mixed plastic waste.

Dow announced additional 'sustainability goals' on the 17th of last month, including producing 100% recyclable packaging products by 2035 and reducing carbon emissions by 15%. A Dow Korea official explained, "This means prioritizing plastic recycling issues even amid the increasing number of COVID-19 cases worldwide."

Domestically, Lotte Chemical is the most proactive, operating the plastic circular economy project 'Project LOOP' on a pilot basis. Since January this year, it has installed 'Nephron,' a PET bottle collection device, at six locations including Lotte World Mall and Lotte World, aiming to collect 10 tons of waste PET bottles by July this year.

Hanwha Solutions has established a plastic recycling development team as a project unit. Vice Chairman Kim Dong-kwan is known to have a strong commitment to this field.

A chemical industry official said, "There is a consensus that if the recycled plastic market grows and demand is not met, companies will fall behind in global competition. Although the existing plastic market will shrink, because recycled products are more expensive, profitability may actually be higher once commercialization is achieved."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.