Prototype and Price Competitiveness of Metal Cutting Processing for Heterostructured High-Entropy Alloys

Prototype and Price Competitiveness of Metal Cutting Processing for Heterostructured High-Entropy Alloys

[Asia Economy Reporter Hwang Junho] Domestic researchers have developed a high-entropy alloy that is stronger and more ductile than existing alloys. This alloy is easy to handle and also cost-competitive. The domestic research team expects it can be used in Korean home appliances through large-scale manufacturing.

The National Research Foundation of Korea announced that Professor Kim Hyungseop's research team at Pohang University of Science and Technology developed a high-strength, high-ductility, and high-workability high-entropy alloy.

The research team proposed a new design method for creating high-entropy alloys. They broke the stereotype that co-entropy alloys must have a uniform atomic form or structure, proving the counterintuitive idea that desired properties can be achieved when composed in an amorphous manner.

Unlike conventional alloys, which add auxiliary elements to a main element, high-entropy alloys are obtained by mixing several elements in relatively equal proportions without a main element. Most are made in a uniform single-phase form, and to maintain this, expensive elements like cobalt and chromium must be added, limiting price competitiveness.

The research team created a high-entropy alloy in a heterostructure form with non-uniform microstructure, grain size, shape, and location-specific structures. They formed iron and copper, which do not mix like water and oil, into two separate domains, then added several elements that can mix these two to maximize heterogeneity in the alloy.

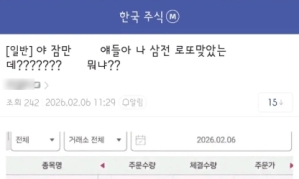

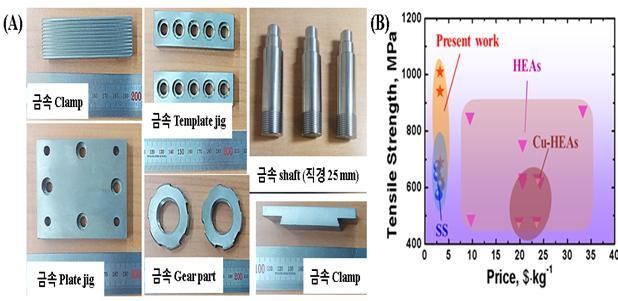

The resulting alloy combines the strength of copper and the ductility of iron. Its strength was found to be about 1.5 times higher than stainless steel. Notably, this alloy is highly cost-competitive. The cutting time for this alloy was reduced to 1/20th of that for stainless steel. Shorter cutting time means reduced material processing costs. Also, the elements needed to mix iron and copper are low-cost materials such as aluminum and manganese, further enhancing price competitiveness.

The research team estimates that this alloy secures about 3 to 10 times higher price competitiveness compared to existing high-entropy alloys.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.