Professor Youngbin Park's Team at UNIST Develops Carbon Fiber-Based Droplet Generator Resistant to Corrosion and Pollution

Raindrop Generator Produces Electrical Signals to Power Drainage Management Systems, Published in Adv. Funct. Mater.

The moment raindrops hit and bounce off a roof, a tiny electric current is generated.

A new technology has been developed that generates electricity from raindrops falling on roofs, enabling drainage devices or alarm systems to operate during heavy rainfall.

The research team led by Professor Youngbin Park from the Department of Mechanical Engineering at UNIST announced on December 15 that they have developed a droplet energy generator (S-FRP-DEG) based on carbon fiber reinforced polymer that produces electricity from raindrops.

Research team (from left) Professor Youngbin Park, Dr. Sunghwan Lee (first author), Researcher Jaejin Kim (first author). Provided by UNIST

Research team (from left) Professor Youngbin Park, Dr. Sunghwan Lee (first author), Researcher Jaejin Kim (first author). Provided by UNIST

Carbon fiber reinforced polymer is a lightweight yet strong material made by mixing bundles of carbon fiber with plastic resin, making it suitable for use as exterior materials such as building roofs.

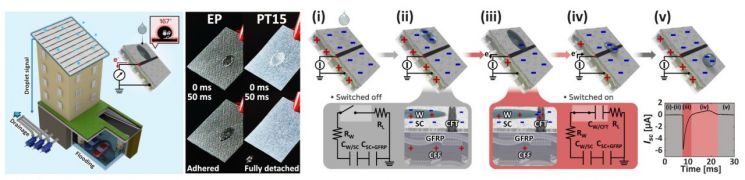

The developed carbon fiber reinforced polymer generator produces electricity the moment a raindrop touches and quickly rolls off the composite surface. The principle is similar to static electricity. Raindrops carry a positive charge, while the composite surface carries a negative charge. When the raindrop contacts and then leaves the surface, charged particles move along the carbon fibers, generating an electric current.

Existing metal-based droplet generators have the problem of metal corroding easily due to contaminants in rainwater. The research team addressed this issue by using corrosion-resistant carbon fiber reinforced polymer.

In addition, the surface of the composite was specially processed and then coated to enhance the generator's performance. The instantaneous contact area of the raindrop was increased, while the drop was designed to quickly bead up and roll off the surface. The finely textured surface increases the contact area, and the coating makes the surface behave like a lotus leaf, causing raindrops to bounce off. The coating also prevents urban pollutants or soot from adhering, allowing the outdoor generator to maintain its performance over time.

In experiments, the developed generator produced up to approximately 60V of voltage and several microamperes of current when a single raindrop of about 92μL (microliters) fell. When four generators were connected in series, they succeeded in momentarily lighting up 144 LED bulbs.

Operating Concept and Electrical Output Process of the Carbon Fiber Reinforced Polymer Droplet Energy Generator (S-FRP-DEG).

Operating Concept and Electrical Output Process of the Carbon Fiber Reinforced Polymer Droplet Energy Generator (S-FRP-DEG).

The research team also demonstrated that the generator could be attached to roof edges or drainage ducts to detect rainfall in real time. The more raindrops that fell, the more frequently electrical signals were generated, and these signals were used to trigger the drainage pump. The number of pump activations varied depending on whether the rainfall was light, moderate, or heavy, enabling the system to distinguish between different flooding conditions.

Dr. Sunghwan Lee and Researcher Jaejin Kim participated as first authors in this study.

Professor Youngbin Park stated, "This technology not only helps manage urban infrastructure such as buildings and bridges and prevent flood damage using only rainwater without any external power source, but it could also be used as a self-powering technology for mobility applications such as aircraft or automobiles that utilize carbon fiber reinforced polymer in the future."

The research was conducted with support from the Mid-Career Researcher Program of the National Research Foundation of Korea (NRF) under the Ministry of Science and ICT. The results were published online on November 20 in the international journal 'Advanced Functional Materials' in the field of materials science.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)