Application in Actual Cultural Heritage Restoration Sites

Publication of 2022-2023 Experimental Results Report

The National Jungwon Institute of Cultural Heritage has successfully produced two cast iron axes and pig iron through ancient ironmaking technology restoration experiments, and used this iron to repair and restore iron artifacts at the Jongmyo Main Hall.

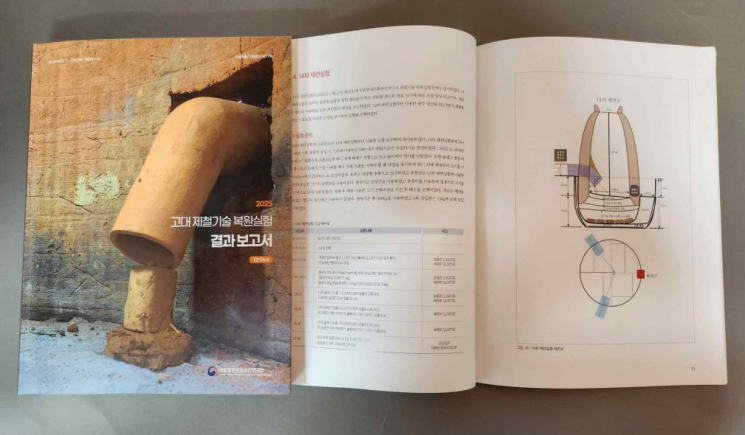

The institute published a results report on the 28th, summarizing the smelting, casting, and forging experiments conducted in 2022 and 2023 to restore ancient ironmaking technology and the outcomes of this research.

According to the report, each experiment conducted at the institute's ironmaking technology restoration site was designed to reproduce the processes and outputs of ancient ironmaking technology and to scientifically verify the level of these technologies.

The sixth casting experiment focused on reconstructing the cast iron axe production process by replicating the melting furnace from the Hwangseong-dong site in Gyeongju. In particular, to address the frequent clogging of the tapping port that had previously disrupted operations, the structure was modified by thinning the inner wall of the furnace near the tapping port. As a result, two high-quality cast iron axes with minimal surface bubbles were produced.

The 12th to 14th smelting experiments involved recreating two tuyeres from the No. 31 furnace at the Chilgeum-dong site in Chungju and blowing air into the furnace. This air-blowing method played a key role in raising the furnace temperature and increasing oxygen supply, thereby accelerating the iron production reaction. Analysis of the produced iron showed that, instead of the initially targeted bloom iron, pig iron with a higher carbon content was obtained.

In the fifth forging experiment, iron material produced during the 2020 smelting experiment was used. The institute repaired and restored the Nuri Gaejeong and Jangsoi artifacts recovered from the Jongmyo Main Hall to their original locations. The institute stated, "We have demonstrated that iron artifacts produced using ancient iron production technology can be applied in actual cultural heritage restoration sites."

The report detailing these research achievements is available for public viewing on the National Research Institute of Cultural Heritage's 'National Heritage Knowledge Link' website.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)