UNIST, Korea Electric Power Corporation Power Research Institute, KAIST, and University of Suwon Develop Technology to Replace Silver Nanowire Insulating Coating

Resistance Reduced by 43%, Enhanced Performance of Silver Nanowire-Based Transparent Heaters... Published in Angewandte Chemie

A new technology has been developed to improve the electrical conductivity of transparent electrodes.

This technology involves replacing the "coating" of silver (Ag) nanowires, which serve as "nano wires."

The silver nanowire electrodes with the replaced coating not only conduct electricity almost twice as well, but also demonstrate enhanced durability. This breakthrough signals significant progress for the development of foldable or rollable flexible display devices using silver nanowire transparent electrodes.

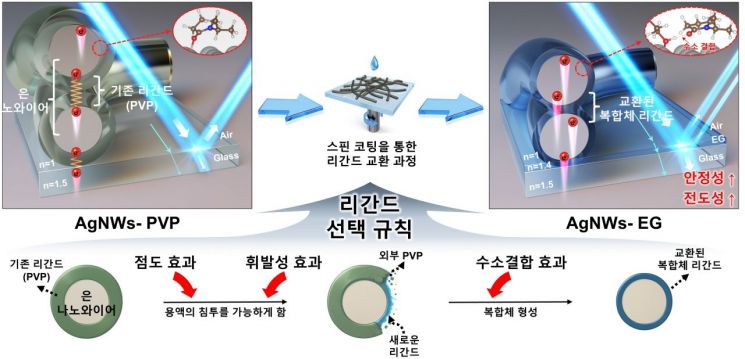

The team led by Professor Taehyuk Kwon of the Department of Chemistry at UNIST, in collaboration with Dr. Jihoon Seo of the Korea Electric Power Corporation Power Research Institute, Professor Eunae Cho of KAIST, and Professor Sangwon Park of the University of Suwon, announced on October 29 that they have developed a technology that simultaneously improves both performance and durability by simply replacing the "insulating coating" of silver nanowires using a solution-based spin coating process.

Research team, (from left) Professor Taehyuk Kwon of UNIST, Dr. Jihoon Seo of Korea Electric Power Corporation Power Research Institute, integrated master's and doctoral student Junhyuk Kwon of UNIST, Dr. Hyunoh Shin of UNIST. Provided by UNIST

Research team, (from left) Professor Taehyuk Kwon of UNIST, Dr. Jihoon Seo of Korea Electric Power Corporation Power Research Institute, integrated master's and doctoral student Junhyuk Kwon of UNIST, Dr. Hyunoh Shin of UNIST. Provided by UNIST

Silver nanowires are metallic threads thousands of times thinner than a human hair. When arranged in an entangled network, they form "transparent electrodes" that conduct electricity while allowing light to pass through. Their flexibility makes them suitable for foldable or bendable electronic devices, but the use of PVP during manufacturing has been a challenge.

PVP is a substance that wraps around the surface of the nanowires to help them grow in a thin and elongated shape, but it also acts as an insulating coating, preventing the flow of electricity. As a result, current is interrupted at the points where nanowires touch, leading to increased overall electrode resistance.

The research team developed a technique to easily replace this PVP insulating layer using an ethylene glycol (EG) solution. By immersing the silver nanowires in the ethylene glycol solution and spinning them rapidly, the PVP is removed and a new conductive layer is formed. This new layer not only enhances current flow, but also protects the silver nanowires from moisture and improves transparency.

Professor Taehyuk Kwon of UNIST explained, "We were able to develop this technology by considering all the physicochemical properties of the replacement material, such as viscosity, volatility, and hydrogen bonding capability."

The silver nanowire electrodes with the replaced insulating layer showed a 43% reduction in resistance, resulting in nearly double the electrical conductivity. These electrodes maintained their performance even in high-temperature (85℃) and high-humidity (85%) environments, and their light transmittance increased slightly, enabling the creation of brighter and more transparent electrodes.

Furthermore, transparent heaters made with these electrodes exhibited more than a 35% improvement in heating performance compared to conventional ones. Due to the lower resistance and improved current flow, the temperature rapidly rose to 140-145℃ within about six minutes after the heater was turned on, whereas conventional silver nanowire heaters only reached up to 102℃.

Dr. Jihoon Seo of the Korea Electric Power Corporation Power Research Institute stated, "For essential power facilities such as electric wires that enrich our lives, the external coating protects the internal metal from the surrounding environment and enhances electrical stability. However, in the case of silver nanowires, the protective coating actually caused electrical resistance. The newly developed technology can replace this with a simple process, without complex equipment or high-temperature treatment, making it applicable to the development of next-generation electronic devices such as flexible displays, wearable sensors, electronic paper, and transparent heaters."

This research was led by Junhyuk Kwon, an integrated master's and doctoral student at UNIST, Dr. Hyunoh Shin of UNIST, and Senior Researcher Junyoung So of the Korea Electric Power Corporation Power Research Institute, who served as co-first authors.

The results were published online on September 30 in Angewandte Chemie International Edition, a prestigious international journal in the field of chemistry. The research was supported by the Korea Electric Power Corporation Power Research Institute, the National Research Foundation of Korea (NRF) under the Ministry of Science and ICT, and the Ulsan National Institute of Science and Technology (UNIST).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.