Korea Federation of SMEs Announces Results of "Survey on AI Adoption by SMEs with Smart Factories"

47.4% Recognize the Need for AI Adoption in Manufacturing Processes

54.6% Express Willingness to Participate in Government AI Support Programs

It has been found that 5 out of 10 small and medium-sized enterprises (SMEs) that have established smart factories recognize the necessity of introducing artificial intelligence (AI) into their manufacturing processes.

The Korea Federation of SMEs announced on October 19 the results of its "Survey on AI Adoption by SMEs with Smart Factories," which included these findings. The survey was conducted from September 16 to September 30, targeting 502 SMEs that participated in the win-win smart factory initiative for large and small businesses over the past five years.

According to the survey, 47.4% of small manufacturing companies that have built smart factories responded that introducing AI into manufacturing processes is (very) necessary. When including those who answered "neutral," the recognition of the need for manufacturing AI adoption rose to 78.5%. Notably, the higher the level of smart factory sophistication-from basic (38.8%) to advanced (58.4%)-the greater the perceived necessity for AI adoption. The areas identified as most in need of AI were: ▲quality control (33.9%), ▲production optimization (32.3%), and ▲process automation (31.9%), indicating a strong demand for improved efficiency and quality in production sites.

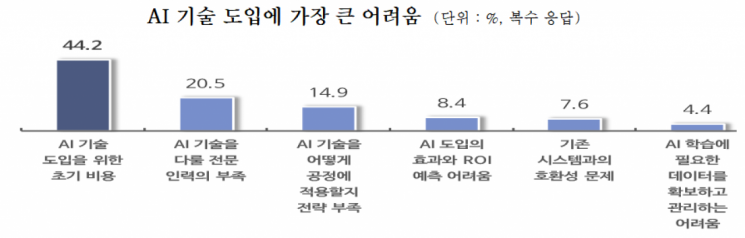

The greatest challenges to adopting AI were cited as ▲the burden of initial costs (44.2%) and ▲a lack of specialized personnel (20.5%). This confirms that the main barriers to AI adoption in SME manufacturing sites are the costs and the shortage of experts. In fact, 68.9% of respondents indicated that their intended investment amount for advancing smart factories with AI adoption was "less than 100 million won."

Despite these practical difficulties, 54.6% of responding companies said they would participate if the government launched a new AI-based smart factory support program (AI Factory), reflecting high expectations for the government's AI transformation support initiatives. The willingness to participate in AI projects was higher among companies with more advanced smart factories, rising from 47.4% at the basic level to 63.2% at the advanced level. The most urgently needed support for AI adoption in small manufacturing companies was ▲direct financial support (72.3%), followed by ▲AI expert consulting (21.9%), highlighting that "direct financial support" for AI solution adoption and related infrastructure is most critical.

Yang Chanhoe, Head of the Innovation Growth Division at the Korea Federation of SMEs, stated, "Since the actual utilization of smart factories and the status of data collection and analysis vary greatly depending on each company's factory level and situation, a two-track policy is needed that not only supports manufacturing AI adoption for the AI transformation but also continues to provide support for basic digital transformation." He added, "We will work together with the government to develop ways to address the burdens SMEs face regarding AI adoption costs and the shortage of smart factory and AI technology experts, as revealed in the survey, so that SMEs can lead the innovation of Korean manufacturing in the era of AI dominance."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.