A domestic research team has succeeded in converting methane, a major greenhouse gas, into eco-friendly bio-materials using a biofoundry.

On October 15, the Korea Research Institute of Bioscience and Biotechnology announced that the research team led by Dr. Seunggu Lee of the National Biofoundry Project Group had successfully demonstrated the possibility of converting methane into eco-friendly bio-materials by establishing an automated biofoundry experimental system (workflow) suitable for industrial applications.

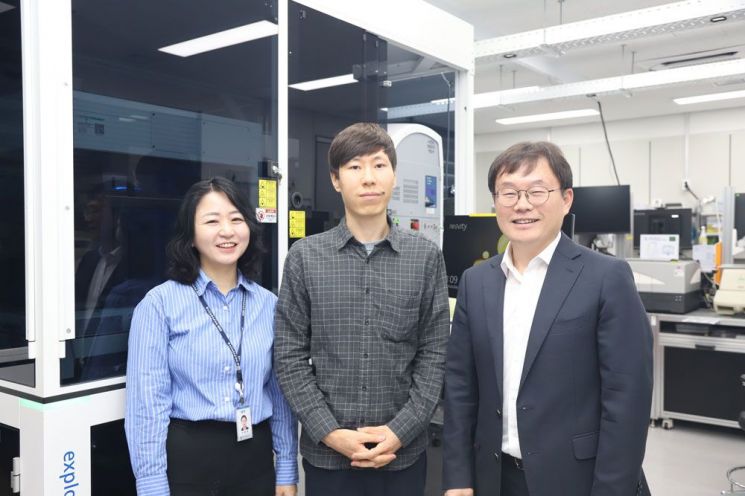

A domestic research team has successfully demonstrated the possibility of converting methane into eco-friendly bio-materials by establishing an automated biofoundry experimental system (workflow). (From left) Dr. Hyewon Lee (co-corresponding author), Georgii Emelianov (first author), Dr. Seunggu Lee (principal investigator). Provided by Korea Research Institute of Bioscience and Biotechnology.

A domestic research team has successfully demonstrated the possibility of converting methane into eco-friendly bio-materials by establishing an automated biofoundry experimental system (workflow). (From left) Dr. Hyewon Lee (co-corresponding author), Georgii Emelianov (first author), Dr. Seunggu Lee (principal investigator). Provided by Korea Research Institute of Bioscience and Biotechnology.

A biofoundry enables the rapid and easy collection of vast amounts of biological data. It is also evolving into an innovative technology by integrating with artificial intelligence (AI).

By repeating the 'design-build-test-learn' cycle to accumulate data and applying AI analysis, the system proposes improved experimental methods and gene designs, thereby increasing the efficiency of developing bio-products such as new materials, pharmaceuticals, and eco-friendly chemicals.

The success of the team's demonstration is significant because it shortens the development period for biocatalysts and engineered microorganisms used in eco-friendly bio-material production and allows the accumulated data to be utilized for AI-based design and analysis.

For example, methane is a representative greenhouse gas whose atmospheric concentration is rapidly increasing. It causes a greenhouse effect more than 84 times stronger than carbon dioxide, but natural pathways for its absorption are extremely limited.

However, as the team's demonstration shows, if methane can be converted into bio-materials, it is expected to bring us a step closer to solving these problems.

In their demonstration, the research team first established an expandable semi-automated workflow. This system, which functions like Lego blocks, allows thousands of large-scale experiments to be conducted easily and flexibly as needed.

Additionally, the team developed a method that combines protein design technology with automation to rapidly produce and evaluate hundreds of protein variants.

Based on this, by automating key processes such as sample preparation, gene assembly, and microbial introduction, the speed of experiments increased by at least 4 times and up to 36 times at each stage. According to the research team, the number of experiments that can be conducted within the same timeframe has also increased significantly, dramatically improving research efficiency.

In particular, the research was applied to improve isoprene synthase (IspS). Isoprene is a key raw material widely used in global industries such as tires, adhesives, and fuel additives. However, existing enzymes either do not express properly or have low activity, which has posed significant limitations for industrial applications.

To address this, the team greatly enhanced enzyme performance using the biofoundry workflow. As a result, the enzyme's reaction efficiency increased by up to 4.5 times, and its thermal stability was also improved.

Notably, when the improved enzyme was introduced into methanotrophs, the productivity of converting methane into isoprene increased significantly. This is regarded as a practical technological solution that can simultaneously address two major industrial challenges: 'reducing greenhouse gases' and 'achieving self-sufficiency in chemical raw materials.'

Dr. Lee stated, "This research is meaningful in that it presents an 'expandable workflow' that integrates computational design, automated experiments, and large-scale data validation. The high-quality data that will be accumulated in the future will enable more precise AI design and learning, thereby accelerating the digital transformation of bio-manufacturing."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)