700 Billion Won Including Initial Operating Costs

At Least 700 Billion Won More for Expansion

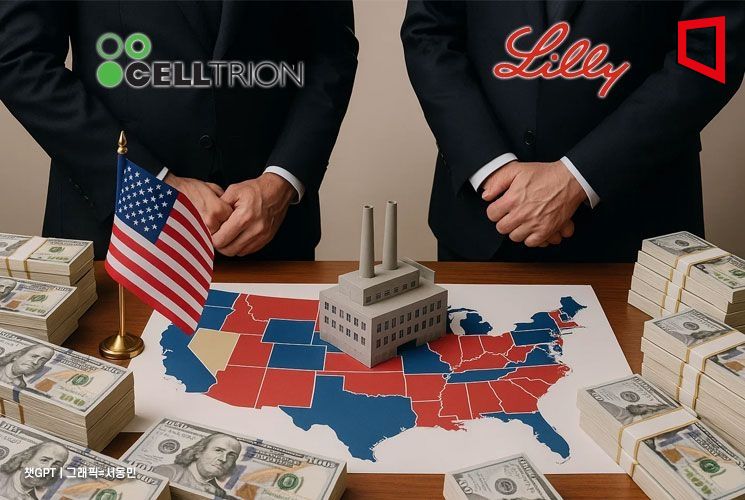

Celltrion has decided to invest more than 1.4 trillion won in acquiring and expanding the U.S. New Jersey plant of global big pharma Eli Lilly.

On the 23rd, Celltrion announced that it had signed a contract to acquire Eli Lilly's biopharmaceutical plant in Branchburg, New Jersey, for approximately 460 billion won. Including the acquisition price and initial operating expenses, Celltrion plans to make a total investment of around 700 billion won. The company also intends to expand production facilities on the idle land within the acquired plant, planning an additional investment of at least 700 billion won. In total, at least 1.4 trillion won will be invested solely in the acquisition and expansion of the plant.

Seo Jungjin, chairman of Celltrion Group, is answering questions from reporters during an online briefing on the 23rd. Celltrion

Seo Jungjin, chairman of Celltrion Group, is answering questions from reporters during an online briefing on the 23rd. Celltrion

Seo Jungjin, chairman of Celltrion Group, stated during an online briefing that day, "We determined that the only way to avoid tariffs in our main market, the U.S., is to produce locally. With this local investment, tariffs will no longer be an issue for us, and now Celltrion is completely free from tariff concerns."

Celltrion Now Free from U.S. Tariffs

The plant to be acquired is a large-scale campus consisting of four buildings-production facilities, a logistics warehouse, a technical support building, and an operations building-on a site of approximately 148,760 square meters (about 45,000 pyeong). It also has about 36,363 square meters (about 11,000 pyeong) of idle land for capacity expansion, enabling Celltrion to proactively respond to future increases in market demand through expansion.

With this acquisition, Celltrion has completed its comprehensive plan to address tariffs. In addition to its mid- to long-term strategies-such as preemptively relocating two years' worth of inventory to the U.S. and expanding contracts with local contract manufacturing organizations (CMOs)-the company has now secured a fundamental solution by acquiring a local production plant. As a result, Celltrion is expected to be free from all potential future tariff risks. Once the production facility is modified and expanded, not only Celltrion's main products supplied in the U.S. but also future products to be launched will be able to avoid the impact of tariffs from the outset.

Choosing Efficiency over Costly New Construction

The plant is already an operational cGMP biopharmaceutical drug substance (DS) production facility, which means Celltrion can begin operations immediately upon acquisition. Compared to building a new plant-which would require more than five years and trillions of won in costs-Celltrion can significantly advance the production timeline for its products and reduce investment costs.

Celltrion plans to begin expanding production facilities at the acquired plant as quickly as possible. Once the expansion is completed, the production capacity is expected to reach 1.5 times that of Celltrion's Plant 2 in Songdo, Incheon.

The contract also includes the complete transfer of all local employees with operational experience and expertise, allowing the plant to be operated without any workforce gaps and ensuring operational stability and productivity.

While building a new plant would require astronomical costs and several years just to prepare for initial operations and secure and train staff, Celltrion will be able to significantly reduce these burdens by acquiring an operational cGMP facility along with its experienced workforce. During expansion, the company also plans to actively utilize New Jersey's extensive talent pool in the pharmaceutical and biotech sectors.

Existing Drug Substance CMO Contract with Lilly... Additional Local Growth Engine Secured

The company has also signed a CMO contract with Lilly, securing a strong growth engine along with establishing a local production base in the U.S. Under the agreement, Celltrion will continue to supply drug substances produced at the plant to Lilly, which is expected to lead to increased sales and faster recovery of its investment.

By securing a local production base, Celltrion can now establish a one-stop supply chain in the market, covering the entire pharmaceutical process from production to sales. Producing locally will also significantly reduce logistics costs to the U.S. and production costs compared to outsourcing to other CMOs, greatly enhancing product competitiveness in the U.S. market.

Celltrion and Lilly have agreed to maintain a cooperative system until the acquired plant is ready with a new operational structure to ensure a smooth transfer of work.

Edgardo Hernandez, Executive Vice President and President of Manufacturing at Lilly, said, "For the past 17 years, the Branchburg plant has been one of Lilly's key manufacturing sites, safely producing high-quality medicines and demonstrating the expertise, responsibility, and dedication of our local team. I would like to express my deep gratitude for the dedication shown by the Branchburg staff over the years and for their contributions to Lilly's mission."

A Celltrion representative stated, "With this acquisition, we have completely resolved the U.S. tariff risk and secured a unified local supply chain from production to sales for our main products. We plan to promptly complete post-acquisition procedures such as plant optimization and transfer of operations." The representative added, "Even after the acquisition, we will continue to invest in expanding our production capabilities and do our best to strengthen our global competitive edge as a leading global company."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.