- Global Launch of "KO-DETECT PRO"

- Digitalization from Imaging and Analysis to Reporting

- Reduces Tasks That Took Six Months to Less Than One Week

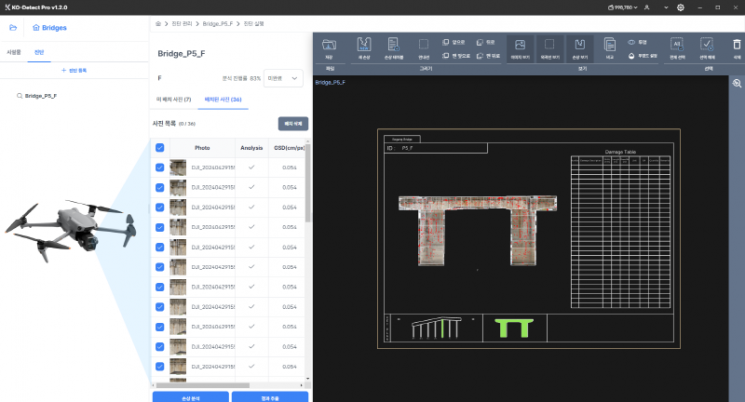

Comapper Co., Ltd. (CEO Kim Dalju), a company specializing in digital safety inspection solutions, announced that it will launch its drone and artificial intelligence (AI)-based facility safety inspection software, KO-DETECT PRO, in the global market.

This solution is provided as a hybrid SaaS model, allowing users to download and use it from anywhere in the world. After being designated as an innovative product by the Public Procurement Service and undergoing solution verification at the Korea Infrastructure Safety and Technology Corporation, it successfully completed its first delivery, thereby proving its technological capabilities. With the launch of this product, Comapper plans to actively target overseas markets, beginning with the establishment of a U.S. subsidiary and the signing of an exclusive distribution agreement in Japan.

KO-DETECT PRO is the world's first commercialized solution that uses AI to automatically analyze facility images captured by drones, detecting and quantifying various types of damage such as cracks, delamination, spalling, efflorescence, and exposed rebar. It was developed to overcome the limitations of traditional manual inspections reliant on human observation. By applying automated detection and analysis technology using drones and AI to facility inspections for the first time in the world, it can precisely detect even micro-damages as small as 0.1 mm.

It enables real-time, comprehensive inspections of structures that are difficult to access, such as construction sites, bridges, tunnels, and dams. The solution automatically organizes large-scale image data and provides time-series comparative analysis to track the progression of damage, supporting the establishment of proactive maintenance plans. In addition, the AI-powered automatic report generation feature instantly produces damage location maps, damage lists and statistics, and quantity calculation tables, allowing for immediate maintenance decision-making right after inspection.

The newly released KO-DETECT PRO is offered in a hybrid SaaS format, satisfying both user convenience and data security. The software can be downloaded and installed from anywhere in the world with an internet connection, ensuring excellent accessibility. The images and result data used for analysis are stored locally on each user's PC. Since critical facility safety data is not exposed to external clouds, users can be assured of security and management. Only functions such as version updates, user authentication, and usage management are provided through the cloud (SaaS). This allows users to enjoy both the data control of an on-premises solution and the convenience of SaaS services, enabling them to conduct safety inspection work using the latest version of KO-DETECT PRO anytime, anywhere.

By adopting KO-DETECT PRO, the precision and efficiency of facility inspections are greatly improved. For example, there was a case where a large-scale structure inspection, which previously required six inspectors over 12 months, was completed by just one or two people in one to two months, achieving at least a 60% reduction in costs. AI automatic analysis minimizes human error, increasing result accuracy, while reducing inspection time by nearly 80%, enabling early detection and response to facility issues.

Non-contact inspections using drones significantly reduce the risk of worker accidents, and all damage data is digitally accumulated, making continuous monitoring and history management possible. Kim Dalju, CEO of Comapper, stated, "KO-DETECT PRO enables more precise and rapid real-time safety inspections, transforming the paradigm of facility maintenance."

Comapper is accelerating its global market expansion with the launch of KO-DETECT PRO. In August, it established a joint venture with its U.S. partner STSC to enter the U.S. Department of Defense procurement market and decided to supply the solution to major countries in Central and South America.

In Japan, the company is preparing to enter the market by signing an exclusive distribution agreement with a local company. The Japanese infrastructure safety inspection market is estimated at about 5 trillion won, roughly 10 times the size of the Korean market. Comapper's strategy is to target this massive market by offering features tailored to local needs, such as earthquake response facility safety inspections.

Additionally, Comapper is in discussions with partners in Singapore, Canada, Germany, and several other countries. The company plans to facilitate the use of KO-DETECT PRO by global customers through localization optimized for regional characteristics, expansion of multilingual versions, and enhanced cloud support.

The innovation and excellence of KO-DETECT PRO have also been recognized externally. Based on its outstanding technology and innovation, the solution was designated as an innovative product by the Public Procurement Service in 2025, making it a new technology prioritized for adoption by public institutions. It was also selected for the Ministry of SMEs and Startups' "Super Gap Startup 1000+ Project," securing government support for future technological advancement and global commercialization.

Leveraging this support, Comapper is further strengthening its super-gap competitiveness in AI-based facility inspection technology. Over the past year, KO-DETECT PRO has been piloted and its field performance verified at various public and private sites, including the Korea Infrastructure Safety and Technology Corporation (a national construction and facility safety management public institution), Seoul Metropolitan Government, Hyundai Heavy Industries, Incheon International Airport Corporation, Hoban Construction, and Jangmin E&C. It is currently being used in actual work. With its wide range of adoption across national, local government, and large enterprise sites, the reliability and effectiveness of the technology have been proven, leading to increased industry interest in KO-DETECT PRO.

Regarding the launch of this new product, Kim Dalju, CEO of Comapper, stated, "In many countries around the world, facility safety inspections are still conducted using analog methods reliant on human visual inspection. With KO-DETECT PRO, the digital transformation of safety inspections is now possible, enabling more precise, easier, and more cost-effective real-time facility inspections." He added, "As an innovative technology representing K-Safety, the global facility safety inspection industry exceeds 300 trillion won. We aim to become the standard and leading company in this vast market." Comapper is committed to continuous technological innovation and research and development to realize this vision and contribute to improving infrastructure safety management standards not only in Korea but worldwide.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.