Few Experts, Only Unskilled Support Staff

Labor Costs Double, Low Skills Raise Quality Concerns

Factories in Rural Areas, Labor Supply Severely Limited

Without Visa and Contract Solutions,

Delays Inevitable from the Start

Labor Sh

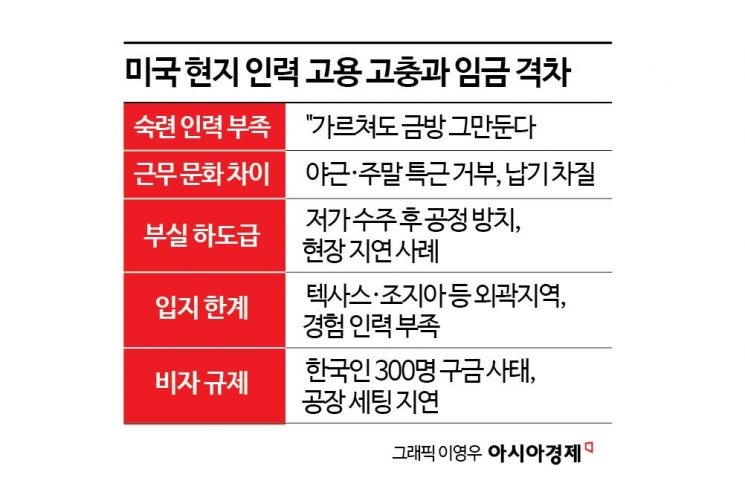

After the recent arrest of Korean workers at the joint factory of Hyundai Motor Group and LG Energy Solution, companies operating local factories in the United States are now facing an immediate labor shortage. While former President Donald Trump has emphasized that foreign experts should train American workers, companies are responding that such demands are out of touch with reality. They argue that initial factory operations are impossible without skilled technicians, and it is also difficult to simultaneously hire and train local workers.

U.S. immigration enforcement authorities released a video on their official website on the 4th (local time) showing the crackdown on illegal residency and employment at the construction site of the joint battery factory between Hyundai Motor Group and LG Energy Solution in Georgia. Yonhap News

U.S. immigration enforcement authorities released a video on their official website on the 4th (local time) showing the crackdown on illegal residency and employment at the construction site of the joint battery factory between Hyundai Motor Group and LG Energy Solution in Georgia. Yonhap News

Labor Costs Double, Lack of Skilled Workers

A representative of a partner company involved in the LG Energy Solution factory project in Georgia told this newspaper on the 10th, "Even when we find workers with visas, most are only qualified for assistant roles. It is nearly impossible to find experts; only unskilled assistants are available in the job market." He explained that while Korean workers are paid about $35 per hour, local workers demand $45 to $60 per hour. Even for simple assistant positions, local hires require around $35 per hour. He added, "Local workers lack skills, are expensive, and issues with work attitude and discipline make stable hiring difficult."

The industry generally agrees that the biggest obstacle in the initial stages, such as equipment installation and line setup, is the lack of skilled workers. Furthermore, even when local recruits are trained, their low level of understanding makes it difficult to deploy them immediately.

It has been reported that the large number of Korean employees caught in the LG Energy Solution project crackdown was due to the phase of the project, which involved the completion of exterior construction, the installation of production facilities, and preparation for trial operations. This stage requires skilled technicians for tasks such as cleanroom construction, power and piping connections, and precise calibration, which is why many Korean workers were present.

A representative from a battery materials company said, "The synthesis process must meet the specifications required by clients, and it takes at least a year of experience to ensure consistent quality. American workers often quit after being trained, so their adaptability is low." He pointed out that frequent turnover and lack of discipline among local workers make quality control virtually impossible. He added, "The starting salary for Koreans is in the 40 million won range (about $28,800), but for Americans, we have to pay at least $65,000 (about 90.27 million won) annually." However, he emphasized, "The bigger problem is not the wage gap, but the instability in quality and delivery deadlines."

Factories Located in Remote Areas, Labor Supply Faces Limits

An executive at a major company said, "First and foremost, we need people, but most of the factories our companies are building in the United States are located in rural areas where young workers are scarce. The biggest problem is being told to build factories in places where there are no skilled workers to begin with." He continued, "It has been a long time since the United States built large-scale manufacturing plants, so there are no experienced workers. Most Americans work in agriculture or the service industry and have no experience with manufacturing processes." Until now, Korean companies have sourced some necessary workers from Latin America, but the recent LG Energy Solution detention incident has blocked visa channels, causing further disruptions.

Another executive from a major company said, "We are preparing a new packaging fab in the Midwest, but since construction has not yet begun, we are deeply concerned about how to manage the workforce." The company currently has only the minimum administrative staff on site to handle land preparation and paperwork. However, once full-scale construction begins, hundreds of skilled workers will be needed, and there are serious concerns that it will be impossible to fill these positions through local hiring alone. He said, "If visa restrictions are not lifted, delays will be inevitable from the very first stages of the process. Without enough people, even contracts are at risk."

Attorney Oh Kyungsik (Dentons Lee Law Firm) said, "Even large companies often outsource construction because managing local workers in the United States is so challenging. For small partner companies, high labor costs and management burdens make them reluctant to hire local engineers." He added, "Some companies are considering hiring Korean Americans or using only a minimal number of local staff, but there is still no clear solution."

The industry argues that, as shown by the recent crackdown and detentions, the visa issue is not optional but essential. Without a solution, even initial factory operations could be disrupted. An industry representative stated, "Without resolving the visa issue, delays in delivery and contract breaches are inevitable. Even if we invest tens of trillions of won, if there are no workers on site, the investment itself could collapse." Another representative said, "The Korean government must make clear demands to the United States. Talking about supply chain cooperation and alliances while blocking visas only creates potential risks for companies."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)