The Physical AI (artificial intelligence) and Small Modular Reactor (SMR) innovative manufacturing localization technology development project, which Gyeongsangnam-do has been pursuing since 2023, will officially be promoted as a government project starting next year.

On August 25, Gyeongsangnam-do held a briefing at the provincial government press center and announced, "The government has designated the development and demonstration project for foundation technologies in physical AI for manufacturing, as well as the next-generation SMR innovative manufacturing localization technology development project, as exempt from preliminary feasibility studies, and will promote them as government projects starting next year."

Yoon In-guk, Director of the Industry Bureau of Gyeongnam Province, is announcing the government's preliminary feasibility exemption news for the Physical AI and next-generation SMR innovative manufacturing localization technology development project and future promotion plans. Photo by Lee Seryung

Yoon In-guk, Director of the Industry Bureau of Gyeongnam Province, is announcing the government's preliminary feasibility exemption news for the Physical AI and next-generation SMR innovative manufacturing localization technology development project and future promotion plans. Photo by Lee Seryung

To become one of the world's top three AI powerhouses, the government has designated four regions-Gyeongnam, Jeonbuk, Gwangju, and Daegu-as AI innovation hubs and exempted these projects from preliminary feasibility studies to support technology development.

Among the four cities and provinces, Gyeongnam is the only one where the national government will fully fund the physical AI foundation technology development and demonstration project for precision manufacturing, without requiring any local government financial contribution.

Physical AI refers to next-generation AI embedded in hardware such as humanoid robots and autonomous vehicles, which can recognize situations and perform tasks autonomously.

The Ministry of Science and ICT plans to invest a total of 1 trillion won-including 600 billion won in government funding and 400 billion won in private investment-from 2026 to 2030 to develop and demonstrate model technologies that can be widely applied across the national manufacturing sector.

The project will also develop and demonstrate AI solutions for various manufacturing processes, including precision control and predictive maintenance that can detect failures or anomalies in advance.

Participants include eight local manufacturing companies such as Shinsung Delta Tech, KG Mobility, CTR, and Samhyun; as well as 25 institutions and companies including Gyeongnam University, Seoul National University, Google Cloud Korea, the Electronics and Telecommunications Research Institute, and Gyeongnam Technopark.

The companies expect that physical AI will reduce process setup time by 60%, defect rates by 50%, and operator dependency by 30%, thereby greatly improving productivity and quality.

The province expects that this project will enable it to secure a leading position in the global market for high-value solutions such as precision control, predictive maintenance, and process optimization, and lead the AI transformation of manufacturing companies, helping Gyeongnam emerge as South Korea's innovation hub for physical AI.

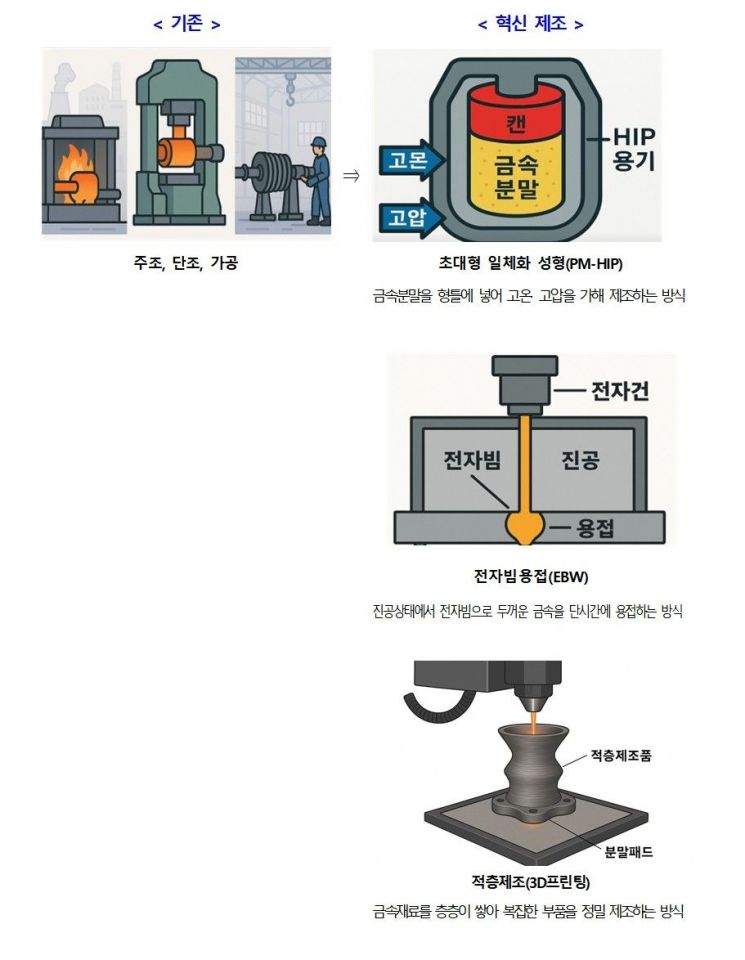

Diagram of existing nuclear reactor technology processes and Small Modular Reactor (SMR) innovative manufacturing technology. Provided by Gyeongnam Province

Diagram of existing nuclear reactor technology processes and Small Modular Reactor (SMR) innovative manufacturing technology. Provided by Gyeongnam Province

The government's other preliminary feasibility exemption project, Small Modular Reactor (SMR), is a next-generation reactor that modularizes key reactor components for factory production, allowing for on-site assembly and installation, and generates up to 300MW of power.

Compared to large-scale nuclear power plants, SMRs offer higher safety and efficiency, and are gaining attention as a next-generation distributed energy source that can be supplied according to demand.

The Ministry of Science and ICT will invest a total of 269.5 billion won-including 112.9 billion won in government funding and 156.6 billion won from other sources-over six years from 2026 to 2031 to develop a system for localizing core equipment and manufacturing technologies that enable mass production of SMRs in the shortest time possible.

The province projects that, by omitting casting, forging, and machining processes required for conventional nuclear power plants, the SMR manufacturing period will be reduced from an average of 14 months to just 3 months.

Based on this project, the province also anticipates that it will be able to provide early support for manufacturing innovation among local nuclear power companies such as Doosan Enerbility, strengthen technological competitiveness, and establish a foothold for capturing the global SMR market.

Yoon In-guk, Director of the Industry Bureau, stated, "By securing leadership in physical AI technologies specialized for manufacturing and the next-generation nuclear SMR manufacturing market, we will transform Gyeongnam into a truly global advanced manufacturing hub."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.