Methane Pyrolysis, Carbon Dioxide Reforming, and Pure Oxygen Combustion-Linked Turquoise Hydrogen Production Process.

Methane Pyrolysis, Carbon Dioxide Reforming, and Pure Oxygen Combustion-Linked Turquoise Hydrogen Production Process.

Korea Institute of Energy Technology (KENTECH) announced on August 20 that Professor Lee Youngdeok's research team, in collaboration with the Korea Institute of Machinery and Materials, has proposed a new turquoise hydrogen production process that does not emit carbon dioxide. This research has demonstrated the potential to overcome the limitations of existing processes and significantly reduce hydrogen production costs.

Turquoise hydrogen is produced by thermally decomposing fossil fuels such as natural gas at high temperatures. It is attracting attention as a new clean hydrogen production technology because it does not generate carbon dioxide during production, and the by-product, solid carbon, can be sold to various industrial sectors. However, the existing process has limitations, such as requiring excessive energy input and low economic feasibility when operated independently.

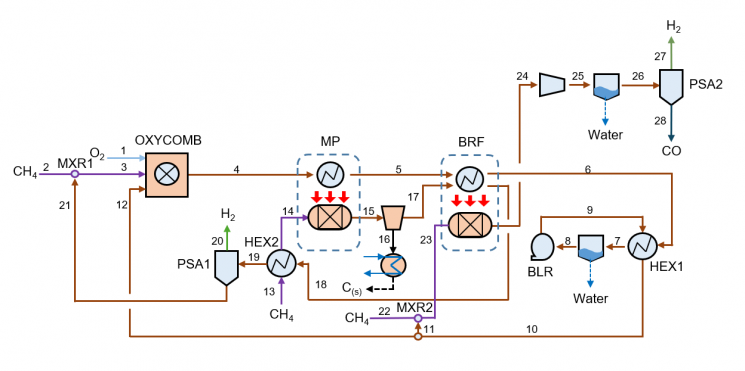

To address these issues, Professor Lee Youngdeok's research team proposed an economical turquoise hydrogen production system concept that integrates ▲Methane Pyrolysis ▲Bi-Reforming (Carbon Dioxide Reforming) ▲Oxyfuel Combustion. This new integrated system links methane pyrolysis with the carbon dioxide reforming process and uses oxyfuel combustion as the heat supply method.

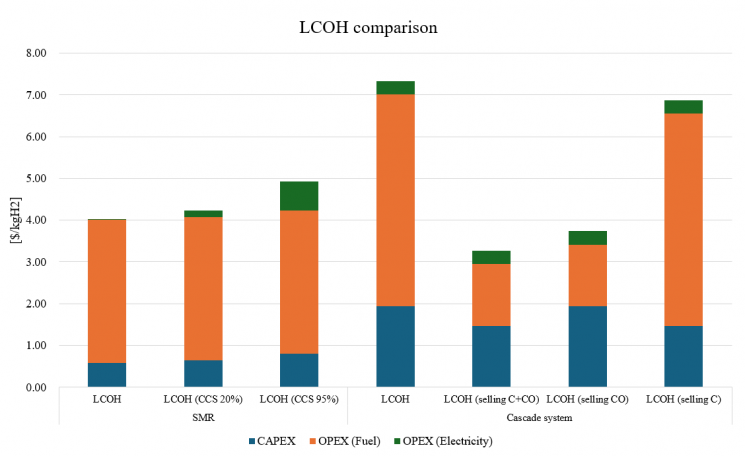

Comparison of Economic Feasibility Between Existing Technology and Turquoise Hydrogen Production Technology

Comparison of Economic Feasibility Between Existing Technology and Turquoise Hydrogen Production Technology

By using the newly developed process, it is possible to produce both turquoise hydrogen and solid carbon. Additionally, carbon dioxide generated within the process can be internally reformed and converted into carbon monoxide, enabling the production of high-value-added compounds.

According to the energy and exergy analysis, the efficiency reached 82.88%. Through the analysis of the levelized cost of hydrogen (LCOH) and sensitivity analysis, the team confirmed the possibility of reducing hydrogen production costs by 20% to 70% compared to existing systems.

Professor Lee Youngdeok stated, "Securing clean hydrogen production technology is becoming increasingly important in preparation for the era of carbon-neutral energy. Although it uses natural gas, this turquoise hydrogen production technology does not emit carbon dioxide and enables the construction of large-scale plants. Therefore, it is expected to become the most efficient clean hydrogen production technology in terms of economic feasibility and domestic supply."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.