Cost Sharing Through Joint Platform Development

Targeting North and Central and South American Markets in 2028

Annual Production Capacity of 800,000 Units Across Five Models

Pursuing Sourcing Projects for Material and Parts Cooperation

Hyundai Motor Group Accelerates Strengthening of U.S.-Focused Supply Chain

Hyundai Motor Group will jointly develop five vehicle models, including a mid-size pickup truck and an electric commercial van, in partnership with General Motors (GM), with whom it has formed a strategic alliance. The two companies have decided to embark on vehicle development in accordance with the memorandum of understanding (MOU) for comprehensive cooperation signed in September last year, and have now unveiled a concrete development roadmap.

These models are strategic vehicles targeting the North American and Central and South American markets and are scheduled for release in 2028. Analysts note that the two companies are not only reducing costs through joint platform development, but are also taking concrete steps to secure a competitive edge in the U.S. market.

On August 7, Hyundai Motor Group and GM announced that they would jointly develop four models?a mid-size pickup, a compact pickup, a compact passenger car, and a compact sport utility vehicle (SUV)?as well as one electric commercial van. Of these, the electric commercial van is being developed for the North American market, while the other four models are strategic vehicles for the Central and South American markets. The goal is to begin mass production and launch in 2028, with the electric commercial van to be produced in the United States. Once mass production of all five models is fully underway, the two companies expect to produce and sell more than 800,000 units annually.

The companies are also pursuing a sourcing project for materials, transportation, and logistics cooperation in the Americas, and are reviewing collaboration in areas such as raw materials, parts, and complex systems. They have also agreed to explore the possibility of working together in the field of carbon-reduced steel to achieve sustainable manufacturing practices.

Hyundai Motor Group Chairman Chung Euisun (right in the photo) and GM Chairwoman Mary Barra pose for a commemorative photo after signing an MOU for comprehensive cooperation in September last year. Provided by Hyundai Motor Group

Hyundai Motor Group Chairman Chung Euisun (right in the photo) and GM Chairwoman Mary Barra pose for a commemorative photo after signing an MOU for comprehensive cooperation in September last year. Provided by Hyundai Motor Group

This announcement is a follow-up measure to the MOU signed in September last year. Although the two companies had been exploring cooperation even before the Trump administration mentioned imposing high tariffs, discussions had not progressed quickly. However, with tariff measures becoming a reality in the second quarter of this year, both companies felt the need for collaboration more acutely, which ultimately led to this concrete agreement.

Jose Munoz, President and CEO of Hyundai Motor, stated, "Based on our cooperation with GM in the North and South American markets, we will be able to provide customers with beautifully designed, high-quality, and safety-oriented vehicles and technologies more efficiently."

Shilpan Amin, GM Senior Vice President of Global Purchasing and Supply Chain, said, "Through this collaboration, we will be able to offer customers a wider range of choices more quickly and at lower cost," adding, "The jointly developed vehicles are a prime example of how both companies can leverage their complementary strengths and scale to create synergy."

Will a GM Pickup Truck Equipped with Hyundai's Hybrid System Be Released?

Hyundai Motor Group and GM plan to enhance product competitiveness by jointly developing platforms, which is the most costly part of vehicle development. By sharing excellent parts supply chains and pursuing joint procurement of parts and materials, they will also secure cost competitiveness. Based on last year's global sales ranking, a simple calculation shows that if Hyundai Motor Group, ranked third, and GM, ranked fifth, join forces, they will be able to share more vehicle parts than Toyota, which is ranked first in production volume.

GM will lead the development of the mid-size truck platform, while Hyundai will lead the development of the compact car and electric commercial van platforms. The vehicle platforms will be developed jointly, but exterior and interior designs will differ by brand, with each company producing and selling the vehicles at their own plants. The four models?mid-size and compact pickups, compact passenger cars, and compact SUVs?will be developed on platforms that can accommodate both internal combustion engines and hybrid systems.

This means that a GM mid-size pickup truck equipped with Hyundai's hybrid system could be launched in the Central and South American markets. At the time of the MOU signing in September last year, there was also discussion of sharing production bases or rebadging (releasing existing vehicles with only the brand logo changed), but the current discussions have focused solely on joint platform development.

Hyundai Motor Group Establishes U.S.-Tailored Supply Chain Strategy

In addition to this collaboration, Hyundai Motor Group is revamping its "U.S.-tailored strategy" to respond to tariffs. The strategy is to concentrate all supply chains?including production facilities and parts for vehicles sold in the U.S.?on the U.S. mainland.

Until now, Hyundai and Kia's U.S. plants exported some of their production to Canada and other parts of North America, as well as to Africa and the Middle East. From now on, however, vehicles produced at U.S. plants will be sold primarily in the U.S. market. Production that was previously carried out offshore and imported to the U.S., such as at Kia's Mexico plant, has also been shifted to domestic production within the U.S. Starting in April this year, Hyundai moved production of the Tucson, which had been contract-manufactured at Kia's Mexico plant, to its Alabama plant.

Automakers are finding it difficult to actively utilize their Mexican plants based on the United States-Mexico-Canada Agreement (USMCA)'s tariff-free provisions. This is because the USMCA imposes much stricter requirements on automobiles?such as employing high-wage workers?than it does on home appliances. The ongoing tariff negotiations between the U.S. and Mexico, as well as the scheduled regular review of the USMCA in June next year, also add to the uncertainty.

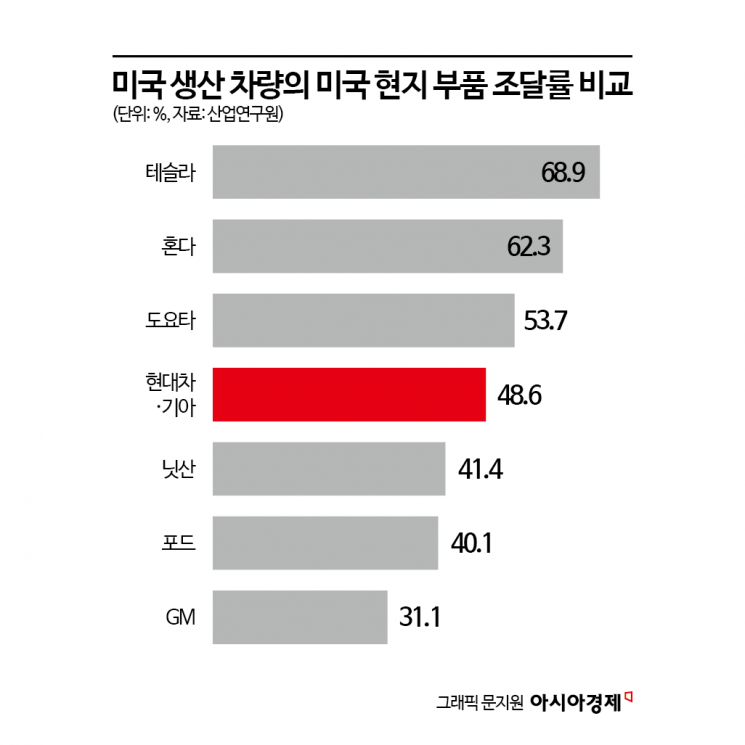

Hyundai and Kia are also seeking to restructure their parts supply chains to focus on local U.S. suppliers. In this process, there is also the possibility of sharing GM's excellent parts network and pursuing joint procurement of parts. According to the Korea Institute for Industrial Economics and Trade, the local parts procurement rate for Hyundai and Kia vehicles produced in the U.S. is 48 percent, compared to 68.9 percent for Tesla, 62.3 percent for Honda, and 53.7 percent for Toyota.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.