Selected as Preferred Bidder for U.S. Plant Acquisition

Production Capacity Can Be Expanded Up to 1.5 Times That of Songdo Plant 2

"Competition Weakens, Profit Margins Likely to Improve"

Celltrion announced on the 29th that it has been selected as the preferred bidder for the acquisition of a biopharmaceutical manufacturing plant located in the United States, surpassing two global companies in the bidding process. Celltrion expects that this will resolve tariff risks and significantly enhance its global competitiveness.

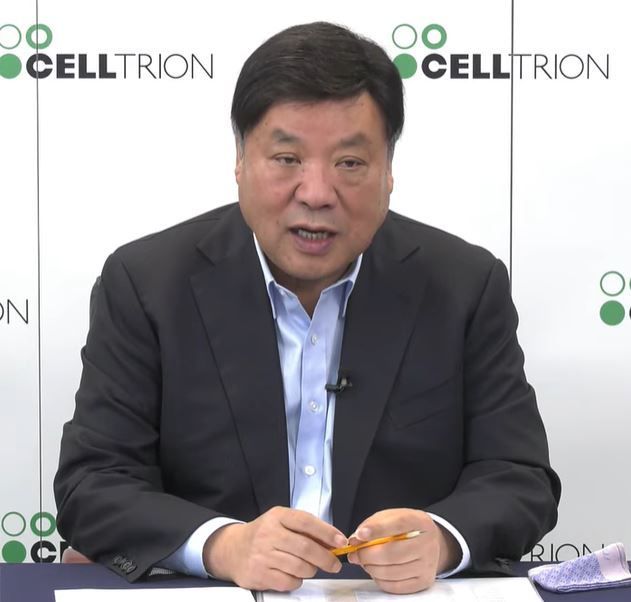

Seo Jungjin, Chairman of Celltrion Group, is explaining the response measures to the US tariff policy at an online press conference on the 29th. Online press conference capture

Seo Jungjin, Chairman of Celltrion Group, is explaining the response measures to the US tariff policy at an online press conference on the 29th. Online press conference capture

Seo Jungjin, Chairman of Celltrion, disclosed this information during an online press conference held in the morning, stating, "We have been preparing for six months, as we determined that acquiring an existing plant is more advantageous both economically and in terms of time. Once the acquisition is completed, we will secure the optimal facility in the United States with both economic efficiency and business viability, and we expect to fully resolve U.S. tariff risks in the shortest possible time."

He continued, "We expect to finalize the main contract before the first week of October and to operate the plant within this year. The total funds required from acquisition to operation are estimated to be around 700 billion KRW. If the U.S. government provides a clear direction regarding pharmaceutical tariffs, we also plan to make additional investments as needed."

Chairman Seo added, "The U.S. market is too large to give up. Barriers to entry in competition may arise, but this could also present new opportunities. I believe the investment is worthwhile."

The plant Celltrion is seeking to acquire is a large-scale drug substance (DS) cGMP (Current Good Manufacturing Practice) facility owned by an undisclosed global pharmaceutical company. Details, including the name of the company being acquired, will remain confidential until the expected signing of the main contract in early October, in accordance with mutual agreement. However, it is known that the plant is located in a major U.S. pharmaceutical industry cluster and has produced key biopharmaceuticals such as anticancer agents and treatments for autoimmune diseases for several years.

Once the acquisition is finalized after due diligence, Celltrion is expected to resolve its U.S. pharmaceutical tariff risks. This move is part of the comprehensive tariff response plan presented by Chairman Seo at a press conference in May. In the short term, Celltrion has already taken preemptive measures such as transferring two years' worth of inventory to the U.S. and expanding contracts with local contract manufacturing organizations (CMOs). With the completion of the local plant acquisition, which serves as a fundamental solution to tariff risk hedging, Celltrion expects to be free from all potential future tariff risks.

Chairman Seo explained, "Through this plant acquisition, we will be ready to produce and sell all products as U.S.-made, regardless of how U.S. tariff policies develop in the future. We will have a lineup capable of providing one-stop services, producing and selling Celltrion products within the United States."

If the final acquisition process is completed, Celltrion will be able to immediately produce its major products sold in the U.S. at the local facility. Currently, 50% of the cGMP facility's capacity is under a CMO contract, allowing exclusive production of the acquired company's biopharmaceuticals for five years, making immediate revenue generation possible after the acquisition. As a result, investment recovery is also expected to proceed rapidly. The remaining 50% will be used to produce Celltrion's major products currently sold in the U.S.

Celltrion plans to immediately begin additional expansion, taking into account trends in U.S. pharmaceutical sales and the timeline for new product launches. Upon completion, production capacity can be expanded to 1.5 times that of Songdo Plant 2. By increasing local production capacity, Celltrion aims to strengthen its responsiveness to the local market and ensure that upcoming new product lines to be sold in the U.S. are also free from tariff impacts from the outset.

After the expansion is completed, it is expected that the local plant will be able to handle the entire production cycle for pharmaceuticals supplied in the U.S., including not only DS but also drug product (DP) and packaging logistics hubs. Celltrion has already established a local sales network, and direct manufacturing is expected to improve cost efficiency and reduce logistics expenses, thereby enhancing competitiveness through lower cost ratios.

Additionally, Celltrion expects that acquiring a local cGMP facility will significantly reduce both time and investment costs compared to new construction. The company aims to efficiently establish a local business ecosystem in the U.S. market, which is the center of the global pharmaceutical industry, encompassing research, production, and sales.

Chairman Seo stated, "Due to tariff policies, drug prices in the U.S. are rising, competition is becoming less intense, and profit margins may improve. For companies that complete investments in the U.S. early, opportunities will arise." He also explained that Celltrion's products have been determined not to be subject to price reductions.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)