KOTRA "Interim Review of the Automotive Industry Supply Chain"

"High Cost Burden, but a Long-Term Response Strategy"

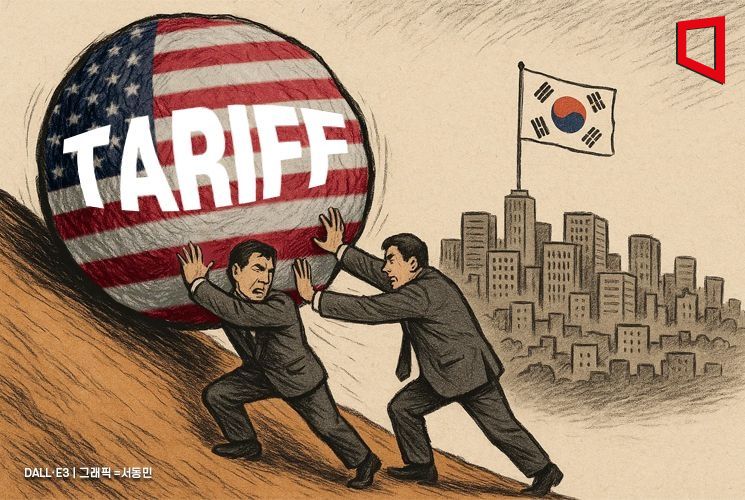

An analysis has found that global automakers are expanding their production in North America as a strategy to respond to U.S. tariff policies.

According to the report "Six Months After the Launch of the New U.S. Administration: Interim Review of the Automotive Industry Supply Chain," released by KOTRA on the 27th, major foreign automakers such as Volkswagen and Toyota are responding to U.S. tariff policies by utilizing production in Canada and Mexico in the short term, while restructuring their production to focus on the United States in the long term.

The United States began imposing a 25% tariff on imported automobiles on April 3, and expanded the 25% tariff to automotive parts starting May 3. However, under the United States-Mexico-Canada Agreement (USMCA), which is a free trade agreement, products from Mexico and Canada are exempt from tariffs if they meet the rules of origin requirements.

According to the report, U.S. automaker General Motors (GM) plans to offset at least 30% of its annual tariff burden of $400 million to $500 million through its production bases in Mexico and Canada.

Stellantis is maintaining its assembly plants in Mexico and Canada as before, while considering producing some models in the United States. Ford is redesigning its distribution channels in Mexico and the United States to meet USMCA requirements.

Toyota is strengthening its North American production base for engines and powertrain facilities located in Mexico and Canada. These companies are pursuing a shift to a U.S.-centered production structure in the long term to increase added value within the United States and to respond to supply chain risks.

GM plans to invest $4 billion over the next two years in three plants located in Michigan, Kansas, and Tennessee, and to shift some of its production volume from Mexico to assembly within the United States. Ford is building electric vehicle and battery production facilities in Tennessee, Michigan, and Kentucky with a total investment of $10 billion.

In addition, automakers are encouraging local production by proposing that key parts suppliers establish factories in the United States, offering to increase supply volumes if facilities are operational within two to three years. Stellantis plans to invest about $5 billion to restart its assembly plant in Illinois and to modernize major plants in Detroit, Toledo, and Kokomo. In Michigan, a new automotive parts logistics hub worth $388 million will be established.

The report stated, "As pressure to avoid high tariffs and to maintain tariff-free benefits increases, there is also growing pressure to restructure supply chains around North America," and added, "Although production in the United States involves significant cost burdens, considering the potential for automation and policy incentives, it is increasingly being re-evaluated as a long-term response strategy."

There is also growing opinion within the global industry that Korean automotive companies need to strengthen their localization capabilities. According to in-depth interviews KOTRA conducted with a total of 29 industry and expert advisory group representatives, officials from the so-called Big Three automakers?GM, Ford, and Stellantis?diagnosed that Korean companies need to move away from an export-oriented approach and strengthen their localization capabilities.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.