The 43rd Automotive Mobility Industry Development Forum

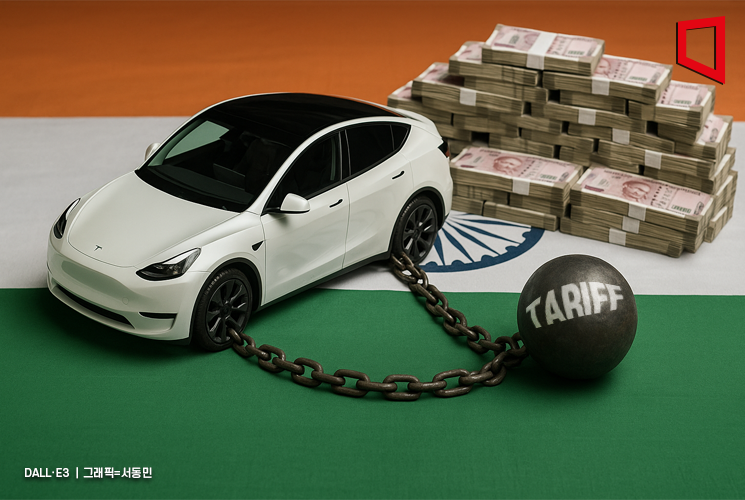

The automotive industry, which is facing both domestic and international crises such as the imposition of U.S. tariffs and sluggish domestic demand, has argued that tax support is needed to promote domestic production.

The Korea Automobile Mobility Industry Association held the 43rd Automotive Mobility Industry Development Forum on July 24 at the Grandeur Ballroom of the Automobile Hall, under the theme "Promoting the Transition to Future Vehicles through Enhancing Production Competitiveness."

Kang Namhoon, Chairman of the Korea Automobile Mobility Industry Association, stated, "A more proactive and comprehensive response is needed to address the complex crisis situation, which includes sluggish domestic demand, tariff burdens, and reduced investment. Major countries such as the United States, the European Union, and Japan are implementing strong policies to protect their domestic industries," he said. "It is urgent to introduce 'domestic production promotion tax support' to strengthen the domestic production base, and it is necessary to expand tax credits for national strategic technologies related to future vehicles," he emphasized.

Lee Hangoo, Research Fellow at the Korea Automotive Technology Institute, diagnosed the structural crisis currently facing Korea's automotive industry in his presentation on "Changes in the Internal and External Environment of the Automotive Industry and Responses." He pointed out, "Amid the 'triple transition' of electrification, digitalization, and artificial intelligence (AI) convergence occurring simultaneously, the intensifying technological hegemony competition between the United States and China, as well as the spread of protectionism, pose a direct threat to Korea's automotive industry, which is highly dependent on exports."

Korea was the world's fifth-largest automobile producer in the early 2010s, but due to the rapid rise of emerging countries such as Mexico and India, it fell to seventh place as of last year. Last year, domestic finished vehicle production decreased by 2.7% year-on-year to 4.13 million units, while overseas production was 3.65 million units, resulting in a domestic production share of only 53.1%.

In particular, Research Fellow Lee cited several serious problems in Korea: polarization due to the size gap between finished vehicle manufacturers and parts suppliers, concentration of talent in the Seoul metropolitan area and outflow of talent overseas, declining competitiveness in autonomous driving technology, and sluggish transition to software-centered parts.

Jung Manki, Chairman of the Korea Industry Federation Forum, analyzed, "The automotive industry has evolved from Fordism (mass production, price competitiveness) to Toyotaism (flexible production, differentiation/diversification), and in the Tesla era, research and development capabilities focused on electric vehicles and autonomous vehicles are becoming increasingly important. While Korea excels in electrification technology, it is in urgent need of addressing its lag in autonomous driving technology. In terms of supply chains, deepening dependence on specific countries is a major risk factor," he said.

To overcome these challenges, he proposed the following: ▲ greater flexibility in labor environments ▲ transformation to software-centered R&D systems ▲ localization of global strategic bases ▲ regulatory innovation for demonstration and commercialization of autonomous vehicles ▲ and revitalization of the market led by the private sector.

Song Junyoung, Team Leader at Hyundai Mobis, introduced the company's AI transformation (AX) strategy to enhance production competitiveness, presenting cases of digital transformation and the establishment of autonomous production systems at the entire process and plant level, going beyond simple automation. He stated, "We aim to reduce R&D costs by more than 50% and achieve a breakthrough innovation in R&D capabilities by utilizing multimodal AI, thereby securing a competitive edge in the future mobility market."

Lee Jiman, Professor at Yonsei University, who participated in the discussion, diagnosed, "During the transition to future vehicles, it is crucial for parts suppliers producing traditional internal combustion engine components to restructure their business models and for workers to be reskilled for new roles. At this point, cooperation between labor and management is more essential than ever to achieve this," he said.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.