[Hyundai Motor, Over the Mobility] (24)

Chairman Chung Euisun Stresses 'Crisis' Right After Record Performance

Instilling Crisis Response DNA in the Organization... Solution-Oriented Mindset

Rising to Global No. 3 by Overcoming COVID-19 and Semiconductor Crises

Building a Purchasing Network That Breaks with Convention

Rapid Shift to Interdepartmental Collaboration During Crisis

'Manpower' Powered by Responsibility and Drive Also Played a Key Role

Chung Euisun, Chairman of Hyundai Motor Group, is speaking at the '2025 Hyundai Motor Group New Year Meeting' held at Hyundai Motorstudio in Goyang, Gyeonggi Province, last January. Photo by Kim Hyunmin

Chung Euisun, Chairman of Hyundai Motor Group, is speaking at the '2025 Hyundai Motor Group New Year Meeting' held at Hyundai Motorstudio in Goyang, Gyeonggi Province, last January. Photo by Kim Hyunmin

This was the message emphasized by Chung Euisun, Chairman of Hyundai Motor Group, at the group's New Year event earlier this year. Last year, Hyundai Motor Group set a new record for its highest-ever performance. Ironically, the keyword Chung chose to introduce the following year's strategy and vision was "crisis." Since becoming Executive Vice Chairman in 2018, the central theme of his New Year's messages has consistently been "change and growth." Why did he recall the notion of crisis at the very moment the group reached its peak growth? It is likely because the DNA of Hyundai Motor Group, which has grown by overcoming past crises, is also deeply ingrained in him.

As Chairman Chung anticipated, Hyundai Motor Group is facing a crisis this year amid global tariff turbulence. The Donald Trump administration has declared a tariff war on the global market, putting the global automotive industry on high alert. The U.S. President has sent letters to governments around the world, warning that tariffs will be raised unless active negotiations take place, escalating the pressure. The Trump administration's approach, which is fundamentally different from traditional tariff negotiations and diplomacy, has left not only governments but also companies in confusion, unable to determine how to respond. In particular, as opinions gain traction that the ultimate targets of U.S. tariffs will be countries with large trade deficits, such as South Korea and Japan, there are growing forecasts that expectations for Hyundai Motor Group's performance should be lowered.

On the surface, concerns about Hyundai Motor Group are growing, but the mood among internal stakeholders I recently spoke with is quite different. Hyundai Motor Group, having overcome numerous crises in the past, has developed a firm belief that it is an organization strong in the face of adversity. This confidence permeates the entire organization. There is even a sense of conviction that they can once again turn crisis into opportunity. A senior official at Hyundai Motor Group emphasized, "If the Trump administration imposes a 25% tariff on automotive products, it will create the same conditions for all global automakers with factories around the world. It won't be easy, but Hyundai Motor Group has more than enough capability to navigate through this crisis."

An Unprecedented Pandemic... Korean Resolve to Overcome Crisis Kept Factories Running

In the 2020s, Hyundai Motor Group faced global challenges of an entirely different scale. The unprecedented "pandemic" that no one could have predicted struck. The COVID-19 pandemic exposed the vulnerability of the global automotive supply chain. It began in China. In January 2020, as COVID-19 first spread in China, Chinese parts factories experienced production disruptions. Hyundai Motor and Kia typically sourced wiring harnesses?a bundle of wires requiring manual labor?from China, but as parts supply issues arose, domestic assembly plants also came to a halt. Hyundai Motor sought alternative production sites in Southeast Asia and elsewhere, and instead of reducing production lines, used "gongpichi" (staggered production) to minimize production setbacks while keeping lines operational.

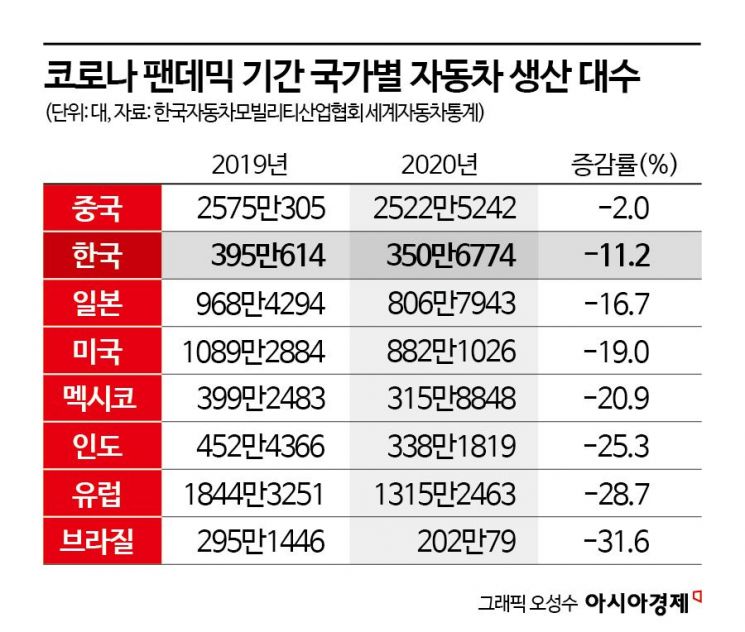

Just as the situation in China began to stabilize, COVID-19 spread worldwide. As the virus rapidly spread to the U.S. and Europe, governments declared national emergencies and closed their borders. With directives to shut down all but essential businesses, society as a whole came to a standstill. Global automotive plants saw their operating rates plummet. In 2020, looking at annual automobile production by country, the U.S. (-19%), Europe (-28%), India (-25%), Japan (-16%), and Mexico (-20%) all saw annual production drop by around 20% compared to the previous year. In contrast, South Korea's decrease was 11%?the smallest among major producers except for China.

The ability of Korean automotive plants to maintain operating rates was partly thanks to the country's robust disease control system. The government implemented rapid diagnostic systems such as drive-through screening centers and the development of test kits, and cut off additional infection routes by sending emergency alerts and tracking and disclosing the movements of confirmed cases. Among these, the most effective system was "social solidarity." The efforts of ordinary citizens, who endured personal sacrifice and inconvenience, became the driving force that kept daily life running. The sacrifices and efforts of Hyundai Motor Group employees also played a crucial role in maintaining operating rates during this period. While factories around the world shut down and production lines stopped, Hyundai Motor and Kia plants in Korea, as the group's home base, continued to operate and even increased output, pulling ahead of competitors.

Domestic demand, which was the only market to show positive growth worldwide, also served as a pillar of support. As more people avoided public transportation, demand for private vehicles rose, and Hyundai Motor and Kia, able to supply vehicles on time, saw their domestic sales increase by about 6% year-on-year. Reflecting on that time, a former CEO of a Hyundai Motor Group parts supplier said, "To meet delivery deadlines, there were times when we isolated thousands of workers in the factory, feeding and housing them on-site. In hindsight, it may seem unreasonable, but at the time, we were truly desperate."

Semiconductor Supply Crisis... Why Hyundai Motor Pulled Ahead

After skillfully overcoming the COVID-19 crisis, Hyundai Motor Group faced another challenge in 2021: the global semiconductor supply shortage. In 2020, the global automotive industry had to reduce semiconductor orders due to decreased production and sales caused by the pandemic. However, as market demand rebounded faster than expected the following year, a worldwide semiconductor supply crisis ensued. Depending on the model, customers sometimes had to wait over a year for vehicle delivery after signing a contract.

From the perspective of the semiconductor industry, the automotive semiconductor market is not its main focus. Semiconductors for home appliances or IT and telecommunications devices account for much larger volumes and higher profitability. As of 2024, automotive semiconductors are estimated to make up only about 10% of the global semiconductor market. Therefore, it is virtually impossible for semiconductor companies to suddenly ramp up production just for automotive chips. Because of this structure, the 2021 semiconductor supply crisis was centered on the automotive industry. However, after weathering this crisis, Hyundai Motor Group rose to third place in global sales rankings. What was Hyundai Motor's secret to increasing its market share in the midst of crisis?

Workers at Hyundai Motor's Ulsan plant are inspecting the quality of the electric vehicle Ioniq 5. Photo by Hyundai Motor

Workers at Hyundai Motor's Ulsan plant are inspecting the quality of the electric vehicle Ioniq 5. Photo by Hyundai Motor

First, Hyundai Motor pioneered an industry-first purchasing network that broke away from established conventions. In the past, it was rare for automakers to directly contact automotive semiconductor manufacturers or foundries. Semiconductor companies typically dealt with first- and second-tier parts suppliers who placed the orders. When the supply crisis hit, Hyundai Motor formed a semiconductor purchasing strategy task force (TF) and responded directly, bypassing the parts suppliers.

The semiconductor distribution structure was more complex than expected. They had to secure leftover quantities from various distribution channels, including direct shipments from semiconductor companies to agents, supplies to global smartphone and home appliance manufacturers, and deliveries to automotive parts suppliers. By communicating directly with semiconductor companies, Hyundai Motor began to notice gaps in supply that were previously invisible when working through parts suppliers. For semiconductor companies, gaining early insight into automakers' production plans made it easier to predict and allocate supply, strengthening mutual trust. Building a semiconductor procurement network centered on the automaker was the first key to Hyundai Motor Group's ability to resolve the supply shortage faster than any other global competitor. The core was a proactive attitude to identify and fix bottlenecks in communication and decision-making, and a solution-oriented mindset unbound by convention.

The second key was the organic collaboration between purchasing, R&D, quality, and production divisions. For supplier diversification, interdepartmental cooperation is crucial. The purchasing division secures as many alternative suppliers as possible and thoroughly checks basic requirements such as price, delivery schedule, and supply stability. After compiling a list of alternative parts, the R&D center evaluates the technical feasibility and compatibility with existing products. At this stage, they determine whether design changes are needed and, if necessary, conduct functional and durability tests. Once technical reviews are complete, the quality division takes over, checking whether new parts meet regulatory and performance standards, and comprehensively reviewing defect rates, durability, and mass-production feasibility. Finally, the production division applies the alternative parts to actual production processes, checking productivity, process stability, and delivery responsiveness, and assessing risks associated with process changes. This entire process can take as little as one year, or as long as two to three years. Hyundai Motor Group consistently secures alternative suppliers in advance, building a broad supply network that allows for rapid deployment of substitute parts if a particular supplier encounters problems.

The final key is Hyundai Motor Group's "manpower"?its human resources. It is the employees on the ground who execute the two strategic approaches mentioned above. Their mindset when implementing these strategies is of utmost importance. Those familiar with the situation at the time agree that "desperation born of responsibility" was the driving force that kept them going. During the semiconductor supply crisis, Hyundai Motor's purchasing division staff made repeated business trips to Europe, where most major semiconductor companies are located. With Europe under lockdown due to COVID-19, there was no guarantee they would even be able to meet with local contacts. Still, they could not just sit and wait. There were many times they had to meet via video call from their hotel rooms or wait near a contact's home, only to return empty-handed. By staying on site, gradually meeting contacts one by one, and getting a feel for market sentiment and developments, the situation slowly began to improve. They were able to identify who the decision-makers were and which items had surplus supply, and only then did the supply of semiconductors begin to trickle in.

A senior Hyundai Motor official familiar with the situation recalled, "At the time, the semiconductor TF staff did not hesitate to travel to Europe despite the difficult COVID-19 situation. In Korea, they also had to work through the night to match the time difference. Driven by a sense of urgency that failure to secure semiconductors could halt the entire production line, they endured nearly a year relying solely on responsibility and a sense of mission." The painstakingly secured semiconductor supplies, like pieces of a puzzle, ultimately became the decisive key to keeping Hyundai Motor Group's factories running. Thanks to the all-out efforts of each division, Hyundai Motor Group achieved its highest-ever global ranking?third among automakers?in 2021. The back-to-back crises of the COVID-19 pandemic and the semiconductor shortage served as real-world tests that validated Hyundai Motor Group's crisis response capabilities.

Overcoming the IMF and Global Financial Crises with 'Counterintuitive Thinking'

Even before the COVID-19 crisis, Hyundai Motor Group had a history of overcoming crises and growing stronger. In 1997, during the Asian financial crisis, domestic demand was cut in half and plant operating rates plummeted. Despite the difficulties of large-scale restructuring, Hyundai Motor adopted an aggressive M&A strategy. The company acquired the struggling Kia Motors, pursued vehicle platform and parts standardization, and leveraged economies of scale to reduce costs. In retrospect, Hyundai Motor's acquisition of Kia laid the foundation for its emergence as a global automotive company.

Another example of overcoming crisis was during the 2008 financial crisis. As global automotive demand plummeted and automakers worldwide cut production, Hyundai Motor Group instead increased production and focused on expanding global sales. At a time when everyone else was shrinking back, Honorary Chairman Chung Mongkoo made bold decisions to proactively boost market share. It was a moment when leadership turned crisis into opportunity. In particular, Hyundai Motor focused on the U.S. market, offering unprecedented terms such as the "10-year/100,000-mile" warranty and the "Assurance Program," which bought back vehicles from customers who lost their jobs, aggressively increasing market share. Thanks to its expanded U.S. presence, Hyundai Motor Group ranked fifth in global sales in 2008, and in the first half of 2009, even surpassed Ford to claim fourth place. In a year when most automakers faltered, Hyundai Motor Group instead laid the groundwork for a leap forward. Once again, it proved that only those who proactively change direction and take action in the face of crisis survive.

Hyundai Motor Group headquarters building located in Yangjae-dong, Seocho-gu, Seoul. Photo by Hyundai Motor Group

Hyundai Motor Group headquarters building located in Yangjae-dong, Seocho-gu, Seoul. Photo by Hyundai Motor Group

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.