Extracting Resources on the Moon,

Manufacturing Products in Orbit

ISM Companies: Manufacturing Directly in Space,

from Pharmaceuticals to Semiconductors

ISRU Companies: Making Space Resource Mining a Reality

Who Will Lead the 6-Trillion-Won Market?

Where Does Korea Stand?

A Signal of Paradigm Shift in Manufacturing

The space manufacturing and mining market, which is expected to grow to over 6 trillion won annually, is reshaping the traditional manufacturing ecosystem.

The current launch cost, which amounts to tens of millions of won to send just 1 kilogram of material into space, has long been the biggest obstacle to space development. When a spacecraft breaks down in space, replacement parts must be manufactured on Earth and sent by rocket. This, combined with the finite resources of Earth and the problem of space debris, has led to fundamental limitations.

Redwire is promoting the Masos project to build infrastructure such as dams, landing pads, and roads on the Moon and Mars. The photo is an artist's rendering of a space base constructed on Mars. Photo by Redwire

Redwire is promoting the Masos project to build infrastructure such as dams, landing pads, and roads on the Moon and Mars. The photo is an artist's rendering of a space base constructed on Mars. Photo by Redwire

Extracting Resources on the Moon, Manufacturing Products in Orbit

The game changers that are overcoming these economic and industrial limitations of space development are In-Space Manufacturing (ISM) and In-Situ Resource Utilization (ISRU) technologies. These two technologies fundamentally transform the value chain of space development. There is no longer a need to carry everything from Earth.

ISM refers to the technology of manufacturing components and structures directly in space, whether in Earth's orbit, on the Moon, or on Mars. If a spacecraft malfunctions, parts can be produced immediately in orbit using 3D printers. Advanced material science enables the creation of high-quality materials, and robotic assembly technology allows for the direct assembly of large structures needed for future space stations or bases. Space itself becomes a vast "smart factory."

ISRU is the technology that supplies the necessary raw materials directly on-site. As the name suggests, it is "local resource utilization" technology, which involves extracting resources such as water, metals, and rare minerals from the Moon, asteroids, or Mars. Water (ice) found at the lunar poles can be mined for rocket fuel and drinking water, while rare metals from asteroids can be brought back to Earth or used as materials for ISM. The entire universe becomes an inexhaustible "resource warehouse."

These two technologies are complementary. ISRU supplies the materials needed for ISM, while ISM provides the equipment and infrastructure necessary for ISRU.

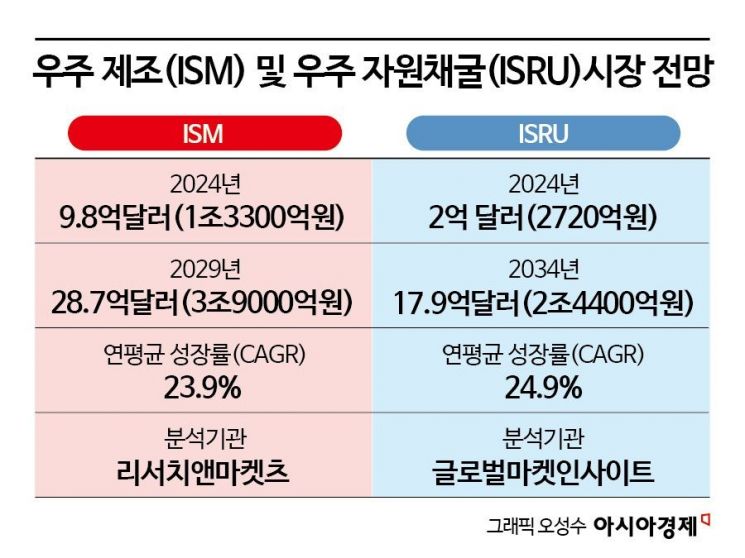

According to Research and Markets, the ISM market is expected to grow from $980 million (about 1.33 trillion won) in 2024 to $2.87 billion (about 3.9 trillion won) in 2029, with an average annual growth rate of 23.9%.

The ISRU market is also projected by Global Market Insights to soar from $200 million (about 272 billion won) in 2024 to $1.79 billion (about 2.44 trillion won) in 2034, with an average annual growth rate of 24.9%.

ISM Companies: Manufacturing Directly in Space, from Pharmaceuticals to Semiconductors

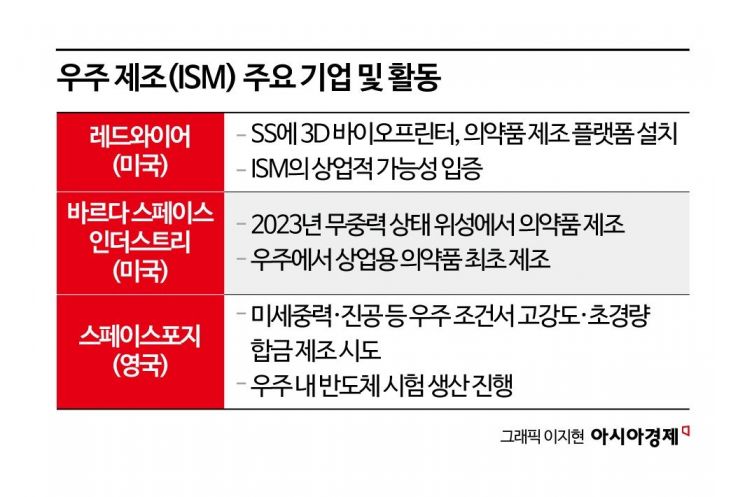

The leading company in the ISM sector is the US-based Redwire. The company has demonstrated the commercial potential of space manufacturing by installing 3D bioprinters and pharmaceutical manufacturing platforms on the International Space Station (ISS).

In 2023, Redwire became the first in the world to print human knee cartilage on the ISS and return it to Earth. In 2024, the company successfully grew insulin crystals in a microgravity environment and brought them back. This process proved that the space environment is effective in improving the quality of pharmaceutical crystals.

Redwire recently began space research for anticancer drug development in collaboration with Aspera Biomedicine. In addition, together with NASA, Redwire is developing landing pads and road construction equipment for use on the Moon and Mars.

Varda Space Industries manufactured crystals of the antiretroviral drug ritonavir in microgravity using its proprietary Winnebago-1 (W-1) satellite in 2023, and safely returned the sample to Earth in February 2024. This is considered the world's first case of commercial pharmaceutical manufacturing in space. Varda plans to expand its missions to produce various high-value-added materials.

British startup Space Forge specializes in producing high-strength, ultra-lightweight alloys, high-performance optical fibers, and next-generation semiconductors by leveraging the unique conditions of space such as microgravity, vacuum, and extreme temperatures.

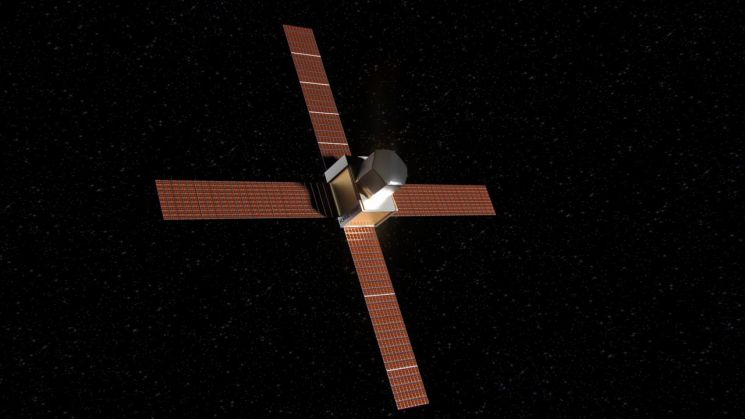

In June 2024, Space Forge successfully launched its first dedicated space manufacturing satellite, Forge Star-1, from Vandenberg Base in the United States. The company is currently conducting experimental semiconductor production and re-entry technology tests in space. As the first private company in the UK to obtain a space manufacturing license, Space Forge is attracting attention for both its technological capabilities and policy foundation.

Space Forge's Forge Star-1, the United Kingdom's first dedicated space manufacturing satellite, successfully launched on the 22nd of last month. Forge Star-1 is currently orbiting in space, validating next-generation semiconductor manufacturing technology and thermal shielding systems. Photo by Space Forge

Space Forge's Forge Star-1, the United Kingdom's first dedicated space manufacturing satellite, successfully launched on the 22nd of last month. Forge Star-1 is currently orbiting in space, validating next-generation semiconductor manufacturing technology and thermal shielding systems. Photo by Space Forge

ISRU Companies: Making Space Resource Mining a Reality

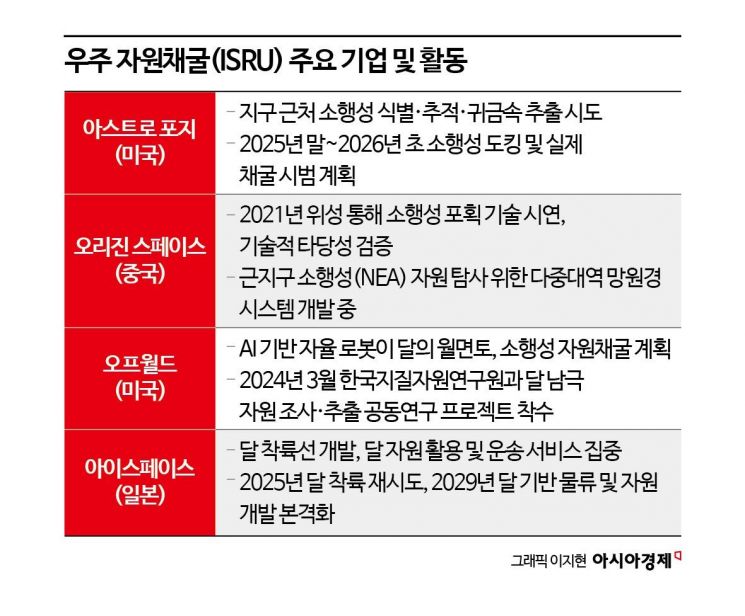

In the ISRU field, US company AstroForge is leading the commercialization of asteroid mining. The company's business goal is to identify and track metallic asteroids near Earth and extract precious metals from them.

In 2024, AstroForge became the first commercial company to launch the satellite Odin toward the asteroid '2022 OB5.' The satellite was intended to fly around the asteroid, capturing high-resolution images and analyzing its metallic composition to collect key data for future mining, but communication was lost. Nevertheless, AstroForge plans to dock with a specific asteroid and conduct an actual mining demonstration through its 'Vestri' mission either later this year or in early 2026.

China's Origin Space launched the 'NEO-1' satellite into a sun-synchronous orbit at an altitude of 500 km in April 2021 to demonstrate asteroid capture technology, thereby verifying the technical feasibility required for future asteroid mining missions. Previously, in 2020, Origin Space announced the 'Yuanwang-1' project, also known as 'Little Hubble,' and has been developing a multi-band telescope system for resource exploration of near-Earth asteroids (NEAs).

US company OffWorld is developing a system in which AI-based autonomous robot swarms perform mining tasks without human intervention. The company plans to utilize lunar regolith and asteroid mineral resources to secure rocket fuel, construction materials, and precious metals. In March 2024, OffWorld, together with the Korea Institute of Geoscience and Mineral Resources (KIGAM), launched an international joint research project on lunar south pole resource exploration and extraction.

Japanese company ispace is well known for its lunar lander development and is currently focusing on lunar resource utilization and transportation services. In May 2024, ispace launched its second lunar lander, Resilience, which successfully entered lunar orbit but failed to land.

However, ispace plans to attempt another landing this year with 'Apex 1.0,' and aims to carry out more than seven lunar-based logistics and resource development missions by 2029, thereby accelerating its lunar resource utilization and transportation services.

Who Will Lead the 6-Trillion-Won Market? Where Does Korea Stand?

While the global space manufacturing and mining market is experiencing explosive growth, Korea remains in the early stages, currently focusing on research and development and building collaborative systems.

Korea's journey into space resource development began in 2021 when Hanwha Aerospace signed a multilateral memorandum of understanding in the ISRU field with the Korea Institute of Geoscience and Mineral Resources and the Korea Aerospace Research Institute. In March 2024, KIGAM expanded international cooperation by launching a joint research project with US company OffWorld for lunar south pole resource exploration and extraction.

Government-level initiatives have also gained momentum. The Korea Aerospace Administration (KASA) included the "Low Earth Orbit Space Factory Project" in its 2024 business plan. This project aims to establish next-generation factories in space to produce advanced products such as semiconductors and new materials, and to develop and demonstrate core Korean space manufacturing technologies. A private-sector-led consortium has been formed with the goal of passing a preliminary feasibility study by 2027.

The Korea Aerospace Research Institute (KARI) is conducting research on lunar resource exploration technologies in parallel with the development of the lunar probe Danuri. In particular, KARI is focusing on detailing a roadmap for exploring potential resources such as water ice and helium-3 at the lunar poles.

The Ministry of Science and ICT has established a long-term strategic roadmap. In December 2022, the Ministry announced its "4th Basic Plan for Space Development Promotion," outlining mid- to long-term strategies for space resource development and utilization. Core tasks include developing technologies for using lunar regolith in lunar base construction and extracting and producing local lunar resources, with the goal of equipping a Korean lunar lander with ISRU technology by the mid-2030s.

Private companies are also becoming more active. Korea Aerospace Industries (KAI), with extensive satellite development experience, has shown interest in developing modules for space base construction and operation. LIG Nex1, which possesses precision control technology, is considering entry into the space robotics and autonomous mining systems sector. Recently, domestic startups researching material development and 3D printing technology for the space environment have also emerged, gradually expanding the diversity of Korea's space manufacturing ecosystem.

An industry insider commented, "Korea has strong growth potential based on the Korea Aerospace Administration's determined drive, large corporations' investments, and the research capabilities of government-funded institutes," adding, "With the government's systematic roadmap and active participation from private companies, we can expect to see tangible results within the next few years."

A Signal of Paradigm Shift in Manufacturing

The rise of space manufacturing and mining technologies is more than just an advancement in the space industry; it signals a paradigm shift for the entire manufacturing sector. Earth-based manufacturers now face the need to diversify raw material supply chains and explore new ways to utilize materials.

In particular, space manufacturing technology is likely to become a game changer in high-value-added sectors such as semiconductors, pharmaceuticals, and aerospace materials. Products with extreme performance that can only be achieved in microgravity and vacuum environments are expected to create new markets.

A researcher at a government-funded institute stated, "However, there are still challenges to overcome, such as technological uncertainty, enormous initial investment costs, and international legal issues regarding space resource ownership," adding, "Nevertheless, the trend of space emerging as a new manufacturing hub is irreversible."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.