Development of AI-Based Technology for Stabilizing Mass Production Quality of Battery NCM Precursors Through Collaborative Research

Real-Time Response to Changes Such as Equipment Aging

Defect Rate Reduced to One-Fifteenth, Published in InfoMat

A domestic research team has successfully applied artificial intelligence (AI) technology to the production process of lithium-ion battery cathode materials, reducing the defect rate and increasing the yield.

It is estimated that this could save more than 2 billion KRW in annual production costs.

The team led by Professor Imdu Jung (who also holds a joint appointment at the Graduate School of Artificial Intelligence) from the Department of Mechanical Engineering at UNIST announced on May 27 that, through joint research with Chief Researcher Giseong Yu's team at the Pohang Research Institute of Industrial Science and Technology (RIST), they have designed process conditions that can reduce the defect rate of NCM precursors and developed AI technology to control these conditions in real time.

NCM precursors are powdery substances composed of nickel (Ni), cobalt (Co), and manganese (Mn), which are agglomerated at high temperatures to produce cathode materials for electric vehicle batteries. The higher the nickel content in the precursor particles, the greater the battery capacity. However, if nickel does not precipitate properly and remains in the solution or is re-extracted, a phenomenon known as "leaching" can occur. Leaching leads to irregular particle shapes and composition ratios, resulting in defects that degrade battery lifespan and performance.

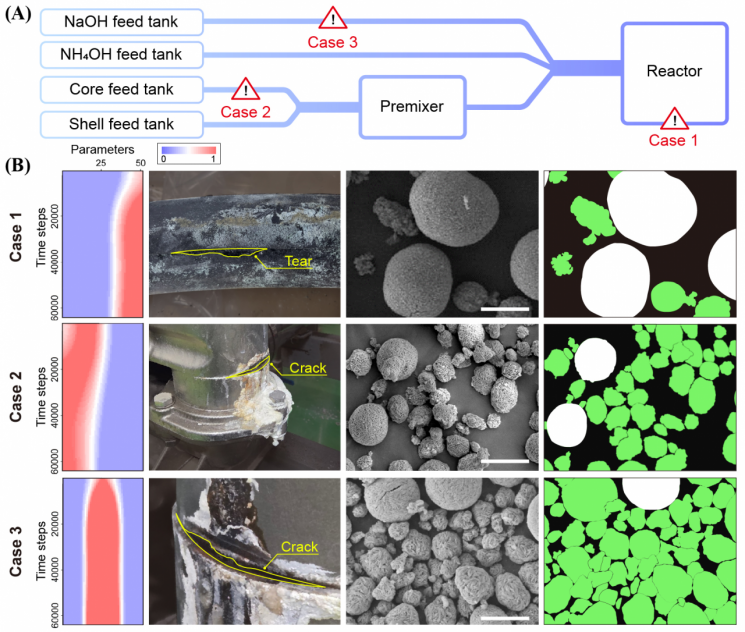

The research team optimized process conditions to suppress such nickel leaching and also developed AI-based real-time equipment anomaly detection technology. By controlling parameters such as the stirring speed of the raw material solution containing dissolved metal ions, acidity (pH), and ammonia concentration, they designed the process so that nickel is positioned inside the particles, while cobalt and manganese are arranged on the outside. When nickel is located within the particle interior, the likelihood of leaching decreases and structural stability increases.

Additionally, they significantly improved defect detection performance using domain adaptation AI technology. Conventional AI systems are optimized only for laboratory-trained conditions, so even slight changes due to equipment aging or prolonged mass production can cause a substantial drop in performance.

In contrast, domain adaptation AI can recognize changes in the production environment in real time and self-correct, enabling stable quality prediction under a variety of conditions.

This research was co-led by Junyoung Seo and Taekyung Kim from the Department of Mechanical Engineering at UNIST as first authors. The research team explained, "When equipment ages or mass production continues, the initially optimal conditions may fluctuate, but domain adaptation AI helps maintain consistent quality by adapting to such changes."

When this AI technology was demonstrated in an industrial-scale 11.5-ton reactor, the number of defective batches was reduced to one-fifteenth of the previous level, and the accuracy of AI-based anomaly detection reached 97.8%. It was also analyzed that this could reduce annual raw material and production losses by approximately 2.2 billion KRW.

Detection of Abnormalities in Production Equipment and Changes in Precursor Sphericity Caused by Defects through AI Monitoring.

Detection of Abnormalities in Production Equipment and Changes in Precursor Sphericity Caused by Defects through AI Monitoring.

Professor Imdu Jung stated, "Unlike small-scale laboratory environments, mass production sites require significant cost and effort to manage quality and yield. This AI technology was successfully applied in the field to enable stable, high-quality production," adding, "It can be applied not only to secondary batteries but also across large-scale manufacturing industries such as chemicals, machinery, and semiconductors."

The research results were published on May 8 in 'InfoMat,' a world-renowned journal in the field of materials science (Impact Factor: 22.7, within the top 3% of JCR).

The research was supported by the Ministry of Science and ICT, the National Research Foundation of Korea, the Institute for Information & Communications Technology Planning & Evaluation, and the Ministry of SMEs and Startups' technology development programs.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.