A domestic research team has resolved the performance degradation issue of "high-nickel cathode materials."

The Korea Institute of Energy Research (KIER) announced on May 22 that the research team led by Dr. Jin Wooyoung and Dr. Cha Hyungyeon at the Ulsan Next-Generation Battery Research and Development Center has newly identified the location of residual lithium compounds, which have long been pointed out as a chronic issue in high-nickel cathode materials, and proposed a design method to minimize residual lithium.

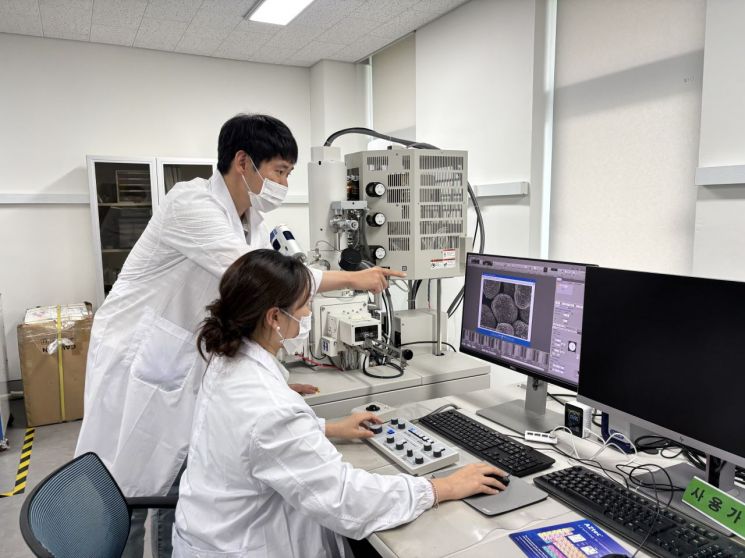

The research team led by Dr. Jin Wooyoung and Dr. Cha Hyungyeon newly identified the location of residual lithium compounds, which have long been pointed out as a chronic issue in high-nickel cathode materials, and proposed a design method to minimize residual lithium. Provided by Korea Institute of Energy Research

The research team led by Dr. Jin Wooyoung and Dr. Cha Hyungyeon newly identified the location of residual lithium compounds, which have long been pointed out as a chronic issue in high-nickel cathode materials, and proposed a design method to minimize residual lithium. Provided by Korea Institute of Energy Research

High-nickel cathode materials are a key component of next-generation lithium-ion batteries used in electric vehicles. The higher the nickel content in the cathode material, the greater the energy density of the battery, which also improves the driving range of electric vehicles. For this reason, high-nickel cathode materials, which contain up to 80% nickel, are attracting attention as a core technology in the next-generation electric vehicle market.

However, as the nickel content increases, excessive amounts of residual lithium compounds are generated on the surface of the cathode material, and a gelation phenomenon occurs in which the electrode raw materials solidify into a jelly-like state.

Subsequently, the particles are not evenly distributed, causing the adhesion between electrode materials to decrease by about 20%, which leads to lower completeness and performance of the electrode. This problem also occurs in commercially available cathode materials, so it was essential to find a solution to this chronic issue for stable production and utilization.

The research team was the first to confirm, contrary to conventional wisdom, that residual lithium also exists between the particles inside the cathode material. In addition, they identified that the internal structure of the cathode material, which had previously been overlooked, is one of the main factors in battery performance and lifespan degradation, and proposed a design direction that can fundamentally suppress the formation of residual lithium.

In particular, using advanced analysis techniques such as high-resolution electron microscopy, nitrogen adsorption analysis, and electron energy loss spectroscopy, the team precisely analyzed the cathode material and confirmed that residual lithium compounds exist in crystalline form in the fine gaps between particles, acting as one of the main causes of performance degradation.

Based on these findings, the team proposed the use of single-crystal high-nickel cathode materials to suppress the formation of residual lithium inside the cathode. Because single-crystal structures have either no or very limited boundaries between internal particles, no gaps are formed between particles, thereby blocking the space where residual lithium could solidify.

The research team expects that using high-nickel single-crystal cathode materials can reduce the amount of residual lithium by 54% compared to conventional cathode materials, making it possible to achieve the industry and academic target of keeping residual lithium compounds below 2,000 ppm.

Dr. Jin Wooyoung and Dr. Cha Hyungyeon stated, "This study is the first case in which the residual lithium issue, previously approached mainly from the surface, was expanded and precisely analyzed based on the internal particle structure. Through this research, we have provided a critical turning point in fundamentally understanding the structural stability and performance degradation of high-nickel cathode materials."

This research was supported by the Ministry of Science and ICT's Global TOP Strategy Research Group Support Program and the Original Technology Development Project. The research paper was also selected as the cover article for the February issue of the world-renowned materials science journal 'Journal of Materials Chemistry A.'

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)