Professor Seungjun Yoo's Team at the Department of New Materials Engineering Achieves Breakthrough

(Photo from left) Younghoon Cho, PhD candidate, Department of New Materials Engineering, GIST; Seungjun Yoo, Professor. Provided by GIST

(Photo from left) Younghoon Cho, PhD candidate, Department of New Materials Engineering, GIST; Seungjun Yoo, Professor. Provided by GIST

On May 13, the Gwangju Institute of Science and Technology (GIST) announced that the research team led by Professor Seungjun Yoo from the Department of New Materials Engineering has developed a technology that can dramatically enhance the performance of redox supercapacitors (Redox EC) by precisely controlling the size of molecules.

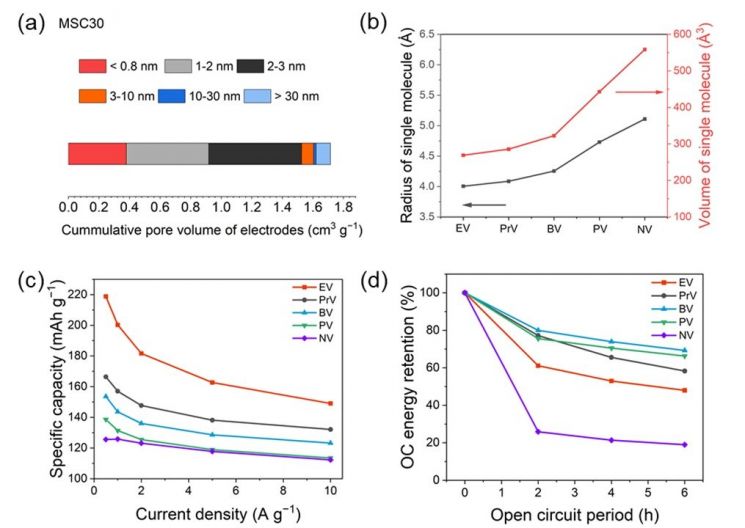

The research team designed the size of organic redox molecules with angstrom-level precision, optimizing them to react effectively with porous carbon electrodes.

A redox supercapacitor is a device that enables additional energy storage by introducing redox-active substances (materials capable of oxidation-reduction reactions) into the electrolyte, allowing these substances to exchange electrons.

Porous carbon is a carbon material with numerous microscopic pores on its surface, resulting in an extremely large surface area and excellent electrical conductivity. These properties make it advantageous for storing electrical energy or promoting chemical reactions, leading to its use in a wide range of fields such as batteries, supercapacitors, adsorbents, and catalyst supports.

Through this approach, the research team succeeded in developing a high-performance aqueous redox supercapacitor with high energy density, low self-discharge, and long lifespan.

Conventional supercapacitors offer advantages such as fast charging speed and long lifespan, but their low energy density limits their storage capacity. Redox supercapacitors, which address these shortcomings, are a next-generation technology designed so that redox-active substances dissolved in the electrolyte can exchange electrons and store additional energy. However, commercialization has been difficult due to issues such as self-discharge caused by the free diffusion of active substances within the electrolyte, and the need to rely on expensive ion-exchange membranes.

To solve these problems, the research team presented a new solution by precisely designing the size of the active substance molecules to fit the fine pore structure of the porous carbon electrode, thereby achieving high performance without the need for a separate ion-exchange membrane.

The core of this technology lies in the reactions that occur at the "interface" where the electrode and electrolyte meet. Previously, the approach was to adjust the pore size of the electrode to control interfacial reactions, but this method had limitations due to its complex manufacturing process and high cost.

Instead, the research team succeeded in ensuring both manufacturing efficiency and performance by shifting the focus from altering the electrode structure to precisely designing interfacial interactions through controlling the molecular size within the electrolyte.

The team synthesized various forms of "viologen" derivatives, which have excellent electrochemical properties, and adjusted them to fit the electrode structure precisely.

Experimental results showed a high energy density of 82.3 Wh/kg at 1.4V, and outstanding durability, maintaining over 95% of its initial performance even after 10,000 charge/discharge cycles. Furthermore, 88.4% of the energy remained after 6 hours post-charging, indicating almost no self-discharge.

Professor Seungjun Yoo explained, "We implemented the optimal electrolyte-electrode combination by precisely controlling the molecular size at the angstrom level to perfectly match the fine pore structure of the electrode," adding, "This research newly identifies the core principle that determines the performance of redox supercapacitors."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.