Ministry of SMEs and Startups Releases Smart Manufacturing Innovation Survey

Only 0.1% of Medium and Small Manufacturers Have Adopted AI

Smart Factory Adoption Rate Stands at 19.5%

While digital transformation (DX) among domestic small and medium-sized manufacturing enterprises has made some progress, the advancement based on artificial intelligence (AI) remains in its infancy.

According to the results of the "1st Smart Manufacturing Innovation Survey" announced on the 28th by the Ministry of SMEs and Startups and the Smart Manufacturing Innovation Promotion Group, only 0.1% of small and medium-sized manufacturing companies engaged in manufacturing had adopted AI. Only 1.6% of companies had plans to adopt it. The percentage of companies with dedicated departments and personnel for manufacturing data and AI also remained at just 0.8%.

Results of the "1st Smart Manufacturing Innovation Survey" announced on the 28th by the Ministry of SMEs and Startups and the Smart Manufacturing Innovation Promotion Group.

Results of the "1st Smart Manufacturing Innovation Survey" announced on the 28th by the Ministry of SMEs and Startups and the Smart Manufacturing Innovation Promotion Group.

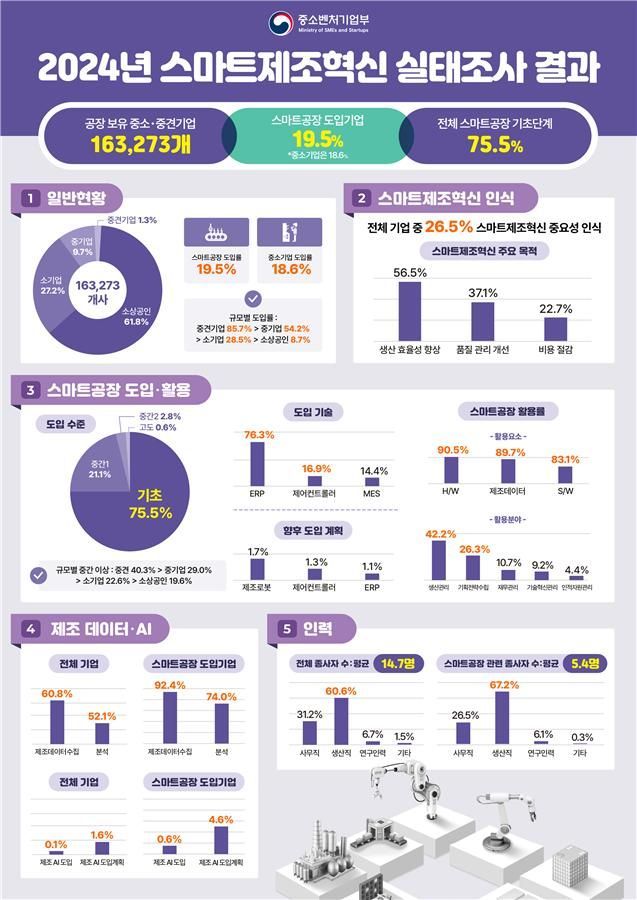

This survey, based on data from 2023, defined its population as 163,273 small and medium-sized manufacturing companies with factories out of a total of 633,182 manufacturing firms. From this population, a sample of 5,000 companies was selected and surveyed through face-to-face interviews conducted from October last year to January this year.

The results showed that the adoption rate of smart factories, which represents the basic level of digital transformation, stood at 19.5%. The adoption rate was 85.7% for medium-sized companies, 54.2% for mid-sized companies, 28.5% for small companies, and 8.7% for micro-enterprises, indicating that the smaller the company, the lower the adoption rate.

About 22.8% of responding companies said they were actively pursuing smart manufacturing innovation, while 26.5% recognized its importance. The main purpose of promoting smart manufacturing innovation was to improve production efficiency (56.5%), followed by quality management improvement (37.1%) and cost reduction (22.7%).

Among companies that had adopted smart factories, 75.5% were at the basic level, and the larger the company, the higher the level of smart factory adoption. The proportion of companies at an intermediate level or higher by size was 40.3% for medium-sized companies, 29.0% for mid-sized companies, 22.6% for small companies, and 19.6% for micro-enterprises. The scope of smart factory adoption was found to be partial in 99.8% of cases.

The average cost invested in building a smart factory was 1.13 billion won, and for small and medium-sized enterprises, it was 750 million won. Of the companies that had adopted smart factories, 56.9% used their own funds for construction. Smart factories were mainly used for production management (42.2%) and business planning and strategy development (26.3%).

Kwon Sunjae, Director of Manufacturing Innovation at the Ministry of SMEs and Startups, stated, "The adoption rate of smart factories is still low, and 75.5% of these are at the basic level," adding, "Based on these results, we will continue to promote policies to expand the adoption of smart factories and foster an ecosystem for digital transformation (DX) and artificial intelligence transformation (AX) among small and medium-sized manufacturers."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.