Developing Second-Generation Sodium-Ion Batteries for Electric Vehicles

Applying Bipolar Technology to All-Solid-State Batteries

LG Energy Solution's Son Kwon-nam, Head of the Next-Generation Battery Development Center, is presenting at NGBS2025 hosted by SNE Research on the 10th. Photo by Kang Hee-jong

LG Energy Solution's Son Kwon-nam, Head of the Next-Generation Battery Development Center, is presenting at NGBS2025 hosted by SNE Research on the 10th. Photo by Kang Hee-jong

LG Energy Solution is focusing on the potential of sodium-ion batteries and accelerating technology development. The goal is to commercialize them ahead of other next-generation batteries before 2030.

On the 10th, Son Kwon-nam, Head of the Next-Generation Battery Development Center at LG Energy Solution, stated at the 'Next-Generation Battery Conference (NGBS) 2025' hosted by SNE Research at EL Tower in Yangjae, Seoul, "As mobility electrification expands further, lithium shortages and price increases are possible," adding, "From a long-term sustainability perspective, the development of sodium-ion batteries is necessary."

Son explained, "The first-generation sodium-ion battery is being developed as a 12-volt uninterruptible power supply (UPS) backup considering output characteristics, while the second generation targets the electric vehicle market with the goal of achieving an energy density of 450 watt-hours (Wh) per liter (ℓ)."

Sodium-ion batteries are secondary batteries that use sodium as the main raw material in the cathode instead of lithium and are also called sodium-ion batteries. Sodium is a resource that is more abundant and easier to obtain than lithium, and it is free from mineral security issues. However, compared to lithium-ion batteries, sodium-ion batteries are heavier and currently have lower energy density at the present technological level. Additionally, due to the lack of economies of scale, their price is still higher than that of lithium-ion batteries.

The battery industry expects that with technological advancements, the energy density of sodium-ion batteries will improve to the level of lithium iron phosphate (LFP) batteries. Once a mass production system is established, prices are also expected to decrease. LG Energy Solution plans to apply dry electrode technology to sodium-ion batteries to reduce production costs.

Son said, "Above all, sodium-ion batteries have the advantage of being able to use the existing lithium-ion battery manufacturing process as is," adding, "We are doing our best to launch them earlier than other next-generation batteries before 2030."

LG Energy Solution's emphasis on sodium-ion batteries appears to be a lesson learned from previously underestimating lithium iron phosphate (LFP) battery technology, which has led to difficulties in the current electric vehicle market. There is concern that if the sodium-ion battery market blooms in the future, the market could again be taken over by China.

Despite some negative views, Chinese companies such as CATL are continuously developing technology, seeing the market potential of sodium-ion batteries. In March, CATL announced that it is developing second-generation sodium-ion batteries with performance indicators approaching those of LFP. SNE Research forecasts that if lithium-ion battery raw material prices rise and the sodium-ion battery market expands, the market size could reach $14.2 billion (approximately 20.67 trillion KRW) by 2035. In fact, Son mentioned, "Electric vehicle manufacturers are also showing interest in sodium-ion batteries."

Not only LG Energy Solution but also domestic battery companies such as Samsung SDI and EcoPro BM are developing sodium-ion battery technology. EcoPro BM is also the lead company for the sodium-ion battery development project under the Ministry of Trade, Industry and Energy. At InterBattery 2025 held last month, Choi Moon-ho, CEO of EcoPro BM, said, "Our sodium-ion battery technology can compete with China."

Currently, the supply chain for sodium-ion batteries is dominated by Chinese companies, which remains a challenge. As of 2024, 83.7% of sodium-ion battery companies are located in China. On this day, Son said, "China has led the supply chain from the early stages, so it controls the supply chain," adding, "It would be good if domestic material companies focus on high-capacity technology and accelerate technology development."

Another next-generation battery technology that LG Energy Solution is focusing on is bipolar batteries. Bipolar technology involves coating both the cathode and anode on a single electrode current collector and stacking them with a separator in between. The current monopolar structure used in lithium-ion batteries coats the cathode and anode on separate current collectors and connects them in parallel.

The bipolar method is attracting attention as it enables the development of high-voltage batteries by implementing a series structure. Son explained, "Bipolar technology can simplify the shell structure, reducing the number of parts by about 50% and improving space efficiency." Ultimately, bipolar batteries can reduce battery costs and extend the driving range of electric vehicles.

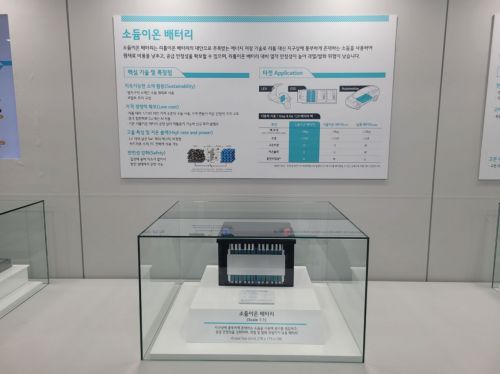

The appearance of the bipolar battery exhibited by LG Energy Solution at InterBattery 2025. Photo by Hee-Jong Kang

The appearance of the bipolar battery exhibited by LG Energy Solution at InterBattery 2025. Photo by Hee-Jong Kang

LG Energy Solution is developing a 120-volt LFP battery using bipolar technology. Son added, "The bipolar battery is being developed in a hybrid form factor of pouch and prismatic." LG Energy Solution is implementing bipolar technology with semi-solid materials and plans to apply the bipolar method to all-solid-state batteries in the future.

Son also revealed that they are developing lithium-sulfur batteries with sulfur cathodes and lithium anodes, achieving an energy density of up to 500 Wh per kilogram. Lithium-sulfur batteries are lighter than conventional lithium-ion batteries, making them applicable in aviation fields such as drones. By using inexpensive sulfur in the cathode, material costs are expected to be reduced by 30-40%.

LG Energy Solution also explained that they are developing all-solid-state batteries with improved lifespan and output characteristics through new cathode coating technology. Son said, "Tests of the newly developed argyrodite sulfide-based solid electrolyte confirmed it has world-class ionic conductivity," adding, "We are currently in the process development stage for mass production."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)