A packaging material that can easily process particulate radioactive waste at low cost has been developed. Particulate radioactive waste refers to fine waste containing radioactive contaminants, which must be handled in a way that prevents dispersion due to the risk of spreading. However, until now, there has been no dedicated packaging material, making the processing procedure complicated and costly. The developed packaging material is expected to contribute to solving these problems.

The Korea Atomic Energy Research Institute announced on the 4th that it has developed a non-dispersive packaging material called ‘Soft Bag’ to block the spread of particulate radioactive waste into the external environment, and has received the first domestic usage approval from the Korea Radioactive Waste Agency (KORAD).

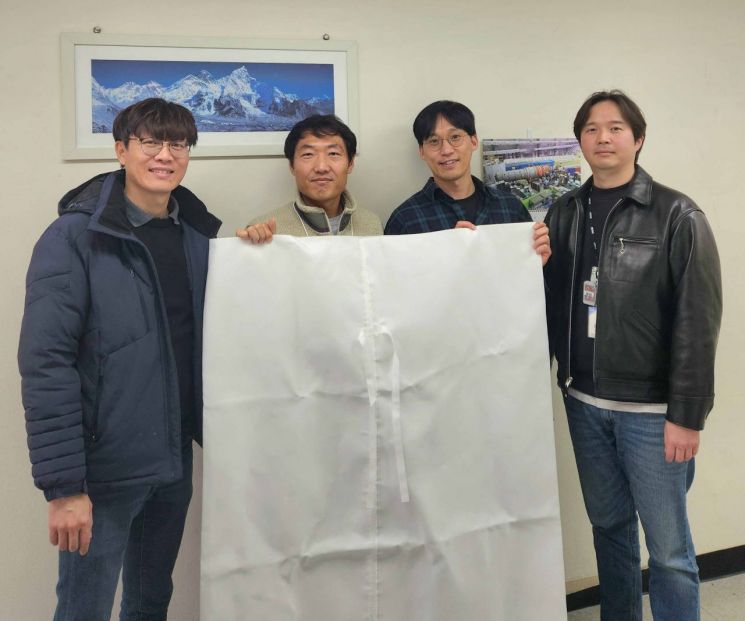

The Korea Atomic Energy Research Institute (KAERI) has developed the country's first non-dispersive packaging soft bag and received the first usage approval from the Korea Radioactive Waste Agency. Members of the research team are posing for a commemorative photo. Photo by Korea Atomic Energy Research Institute

The Korea Atomic Energy Research Institute (KAERI) has developed the country's first non-dispersive packaging soft bag and received the first usage approval from the Korea Radioactive Waste Agency. Members of the research team are posing for a commemorative photo. Photo by Korea Atomic Energy Research Institute

Particulate radioactive waste refers to waste containing particles with a diameter of 0.01 mm or less at 1% or more, or particles with a diameter of 0.2 mm or less at 15% or more.

Until now, there was no dedicated packaging material for particulate radioactive waste, so a ‘sieving separation’ process had to be performed for treatment. In this process, waste larger than a certain size that does not pass through the sieve is packaged and permanently disposed of, while fine particles that pass through the sieve undergo a separate solidification process using cement or other materials. In the latter process, the volume of waste increases, leading to higher disposal costs.

To solve these problems, Dr. Eun Hee-cheol’s research team at the Radioactive Waste Management Office of the Korea Atomic Energy Research Institute developed a new Soft Bag that meets all acceptance criteria required for usage approval, including drop and immersion (IPX7 grade) tests.

The research team conducted a ‘drop impact test’ by filling the Soft Bag with over 350 kg of waste and dropping it freely from a height of 1.2 meters to evaluate whether there was any loss or damage to the contents, and a ‘water penetration test’ by submerging it in water at a depth of 1 meter for 30 minutes to check for immersion. Both tests were passed successfully.

Notably, polypropylene fabric, which is resistant to corrosion and chemically inert, was applied to the Soft Bag to enhance strength and durability.

Additionally, a special sewing method using high-strength yarn was applied, and the size was made compatible with a 200-liter drum to improve compatibility with existing disposal methods. Standardized guidelines were provided for the most effective use of the packaging material, including the size and position of binding straps and knot loops, enabling anyone to package with consistent strength and allowing easy use of the Soft Bag on site.

Applying the developed Soft Bag also offers the advantage of eliminating the need for sieving separation and solidification processes. The process is completed simply by packaging particulate radioactive waste in the Soft Bag and placing it into a disposal drum. Because particulate radioactive waste can be packaged and directly permanently disposed of, the processing time is reduced by more than 90% compared to the existing method, according to the research team.

The Soft Bag developed by the research team is scheduled to be used starting next month for packaging radioactive contaminated soil generated at nuclear power plant dismantling sites. When applied, it is expected to save more than 8 billion KRW per 1,000 drums in costs.

The research team plans to continue cooperation with waste-generating institutions, regulatory agencies, and disposal operators to expand the application targets of the Soft Bag in the future.

Earlier, the Korea Atomic Energy Research Institute completed domestic patent application for the Soft Bag last month and transferred related technology and know-how to OrbiTech Co., Ltd. this month.

Park Sung-bin, head of the Radioactive Waste Integrated Management Division, said, “We will contribute to securing on-site technology for nuclear power plant dismantling waste treatment by establishing a system to expand the application of this research result to radioactive concrete waste.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)