Innovative Changes Expected in Medical, AR, and VR Interfaces with KAIST Research Team's Nano-Gap Pressure Sensor

On the 10th, a research team led by Professor Yoon Jun-bo of the Department of Electrical Engineering at the Korea Advanced Institute of Science and Technology (KAIST) announced the development of a 'nano-gap pressure sensor' that can detect pressure with high resolution without being affected by external interferences such as ghost touches, which occur when water droplets from rain or showering get on a smartphone screen and cause erroneous touch recognition.

From the left, Professor Yoon Jun-bo, Dr. Yang Jae-soon. From the top left, Integrated Master's and Doctoral Course student Jung Myung-geun, Professor Yoo Jae-young of Sungkyunkwan University. Provided by KAIST

From the left, Professor Yoon Jun-bo, Dr. Yang Jae-soon. From the top left, Integrated Master's and Doctoral Course student Jung Myung-geun, Professor Yoo Jae-young of Sungkyunkwan University. Provided by KAIST

The commonly used 'capacitive pressure sensor' in touch systems has a simple structure and excellent durability, making it widely used in human-machine interface technologies for smartphones, wearable devices, robots, and more. However, it has a critical problem of malfunction caused by external interference factors such as water droplets, electromagnetic interference, and bending due to curvature.

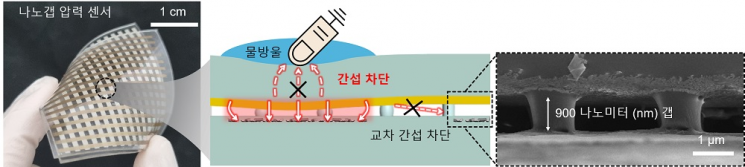

Professor Yoon's research team identified that the cause of interference in capacitive pressure sensors is the 'fringe field' generated at the sensor edges, which is extremely vulnerable to external interference. To suppress the fringe field, they narrowed the electrode gap to the scale of several hundred nanometers (nm), thereby reducing the fringe field generated in the sensor.

Utilizing proprietary micro/nano-structure processing technology, the research team developed a nano-gap pressure sensor with an electrode gap of approximately 900 nm. The developed sensor detected only pressure regardless of the material applying the pressure and was verified to have no impact on sensing performance even under bending or electromagnetic interference.

Using the characteristics of the developed sensor, the research team also implemented an artificial tactile system. Human skin contains pressure receptors called Merkel's discs that detect pressure. To mimic this, pressure sensor technology that responds only to pressure without reacting to external interference was required, but existing technologies struggled to meet these conditions.

Conceptual diagram of the 'Nano Gap Pressure Sensor' developed by the research team. Provided by KAIST

Conceptual diagram of the 'Nano Gap Pressure Sensor' developed by the research team. Provided by KAIST

The sensor developed by the research team not only overcame these shortcomings but also reached a density level comparable to Merkel's discs, enabling the implementation of an artificial tactile system capable of precise wireless pressure detection. Additionally, they developed a force touchpad system, confirming its applicability to various electronic devices and verifying that pressure magnitude and distribution can be obtained at high resolution without interference.

Professor Yoon stated, "The nano-gap pressure sensor operates stably without malfunctioning like existing pressure sensors even in rainy or sweaty conditions. We expect it to resolve inconveniences many people have experienced in daily life," adding, "It can bring innovative changes in various application fields such as precise tactile sensors for robots, medical wearable devices, and augmented reality (AR) and virtual reality (VR) interfaces."

The research, conducted with first authors Dr. Yang Jae-soon of KAIST's Department of Electrical Engineering, Ph.D. candidate Jung Myung-geun, and Assistant Professor Yoo Jae-young of Sungkyunkwan University's Department of Semiconductor Convergence Engineering (a KAIST Ph.D. graduate), was published on the 27th of last month in the prestigious international journal Nature Communications. (Paper title: Interference-Free Nanogap Pressure Sensor Array with High Spatial Resolution for Wireless Human-Machine Interfaces Applications)

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.