Diameter of 1.5 μm,

Inspired by Hagfish Slime

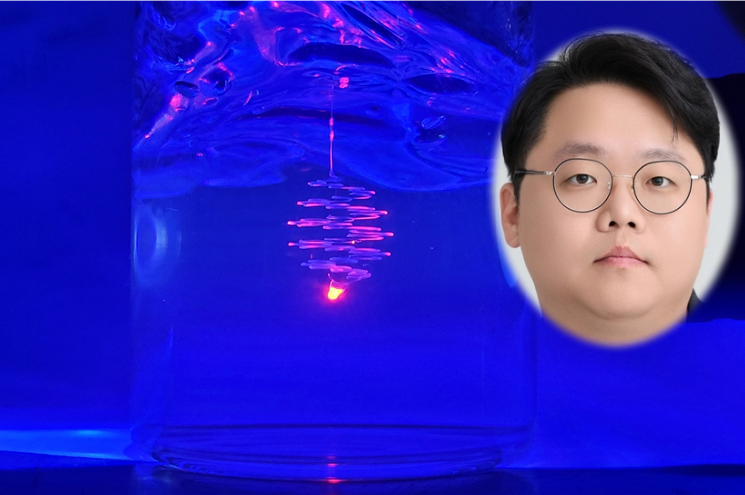

Dankook University announced on the 7th that a research team led by Professor Eom Wonsik from the Department of Polymer Science and Engineering has developed a 3D printing method capable of producing fibers 100 times thinner and tougher than human hair.

With conventional 3D printing technologies, it has been difficult to produce fibers with a diameter of 16 micrometers (μm) or less?comparable to human hair?due to issues with surface tension causing the fibers to break easily.

Professor Eom's team was inspired by the process in which hagfish slime transforms into threads, leading them to develop a new method.

When threatened, hagfish secrete a slime composed of fibrous material, which turns into strong threads upon contact with water.

Specifically, the method uses a solution of SEBS polymer and toluene as ink, which is printed inside a hydrogel composed of a mixture of ethanol and water.

At the moment of printing, toluene is extracted from the solution, and the ethanol in the hydrogel reacts with SEBS, causing it to solidify.

Using this technology, it is possible to print ultra-fine fibers with a diameter as small as 1.5 μm at speeds more than 500,000 times faster, and it can also be applied to thermoplastic polymer materials such as rubber and plastic.

Professor Eom Wonsik stated, "We have overcome the limitations of conventional 3D printing technologies and can now produce ultra-fine fibers quickly and stably through a new method inspired by nature. We expect this will lead to innovations in various industrial fields, including minimally invasive medical drug delivery devices and robotic tactile sensors."

The research team included collaborators from the University of Illinois in the United States, the University of Cambridge in the United Kingdom, and Hongik University, and was supported by the Defense Advanced Research Projects Agency (DARPA) under the U.S. Department of Defense.

This research was published in Nature Communications under the title "Fast 3D printing of fine, continuous, and soft fibers via embedded solvent exchange."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.