Simultaneous Reduction Catalyst for Three Fine Dust Precursors Developed

First Report on the Simultaneous Reduction Mechanism and Commercialization Verified

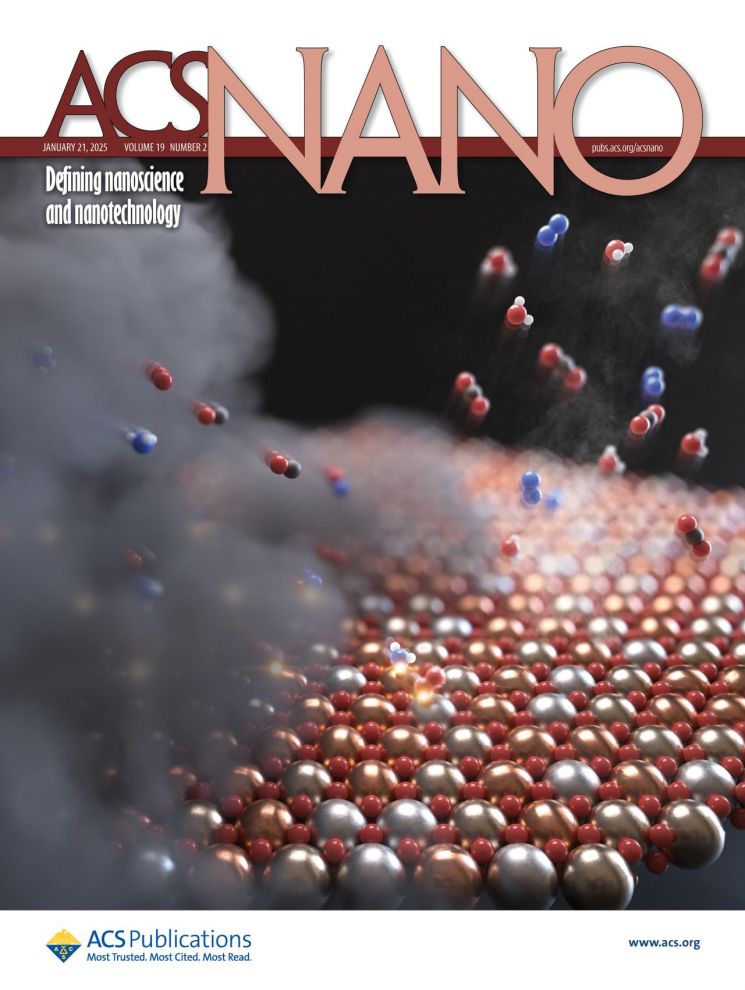

Selected as a Cover Paper in ACS Nano

A substance capable of efficiently reducing the unwelcome springtime fine dust has been developed.

Professor Seungho Cho's team from the Department of Materials Science and Engineering at UNIST, in collaboration with Dr. Hongdae Kim's team from the Korea Institute of Industrial Technology and Dr. Kwangyoung Kim from the Korea Institute of Energy Research, developed a catalyst that can simultaneously remove three types of fine dust precursors.

Fine dust precursors such as nitrogen oxides (NOx), carbon monoxide (CO), and ammonia (NH3) are mainly emitted from industrial sites. These precursors react in the air to form hazy fine dust particles.

In particular, nitrogen oxides have a global emission volume reaching 100 million tons and are highly toxic. To convert these nitrogen oxides into harmless nitrogen, ammonia is introduced to chemically react with a catalyst, but unreacted ammonia flows out again. The residual ammonia is then removed by reacting it with carbon monoxide in the exhaust gas using another catalyst. This method requires two types of catalysts, which reduces economic efficiency and occupies a large amount of facility space.

ACS Nano cover image. It depicts the reaction of fine dust precursors on the catalyst surface (the material spread on the bottom).

ACS Nano cover image. It depicts the reaction of fine dust precursors on the catalyst surface (the material spread on the bottom).

The newly developed metal oxide catalyst (Cu-Ni-Al) performs the functions of two catalysts and simultaneously removes the three types of precursors. The conversion rates representing removal performance were 93.4%, 100%, and 91.6% for NOx, CO, and NH3, respectively.

Additionally, the nitrogen selectivity was also high at 95.6%. High nitrogen selectivity means that harmful reaction byproducts such as nitrous oxide did not occur.

The research team also identified the optimal gas mixture ratio for the catalyst to achieve the best performance. They elucidated the simultaneous reduction reaction mechanism for the first time and, based on this, proposed the optimal ammonia injection ratio under carbon monoxide-rich conditions.

They also verified the performance for commercialization. When the mass-produced powdered catalyst was formed into a pellet shape capable of withstanding the high-velocity environment of an actual factory and tested, it still showed high conversion rates.

Professor Seungho Cho, who led the research, explained, “The developed catalyst can be used even at a relatively low temperature of 225°C, and it shows excellent performance even in pellet form, so commercialization is expected.”

This research involved Wonshik Jang and Myungjin Lee from the Department of Materials Science and Engineering at UNIST as first authors. The pellet catalyst demonstration study was led by the Korea Institute of Industrial Technology, and the catalyst mechanism analysis was led by the Korea Institute of Energy Research.

The research results were selected as the cover paper of ACS Nano, a prestigious journal in the field of nanoscience, and published on January 21.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.