Pusan National University, Sungkyunkwan University, and Mississippi State University Verify Saicox Layer of Silicon, Oxygen, and Copper for Oxidation Suppression

Formation of SiFeOx and SiNiOx Layers on Surfaces of Iron, Nickel, and Other Metals Also Confirmed to Block High-Temperature Oxidation

On the 11th, the research team led by Professor Emeritus Jeong Se-young of the Department of Optical Mechatronics Engineering at Pusan National University (President Choi Jae-won), in collaboration with Sungkyunkwan University and Mississippi State University in the United States, announced the development of a groundbreaking technology that introduces an atomic single-layer barrier film to prevent oxidation at high temperatures while maintaining copper's electrical conductivity.

Using the ASE (Atomic Sputtering Epitaxy) method, silicon (Si) was deposited, demonstrating suppression of metal surface oxidation even at high temperatures of 400°C.

The 'ASE method' is a thin-film growth technology developed in Professor Jeong Se-young’s laboratory at Pusan National University, capable of growing metal thin films without grain boundaries at an atomic single-layer scale (approximately 0.2 nm roughness).

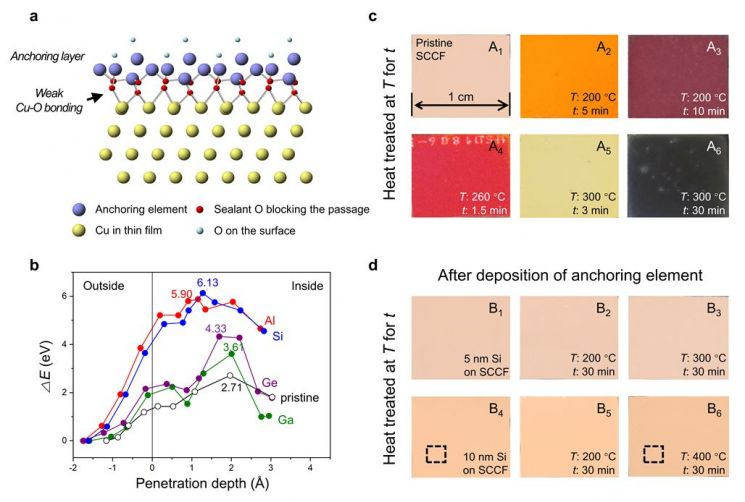

Generally, copper undergoes oxidation even at room temperature, and the oxidation rate increases sharply as temperature rises. In previous research ('Nature 603, 434 (2022)'), Professor Jeong’s team revealed that copper surfaces composed of atomic single-layer step structures (ultra-flat surfaces) can prevent oxidation at room temperature. However, even copper thin films with ultra-flat surfaces undergo oxidation when heated, resulting in various colors depending on the thickness of the oxide layer.

In this study, the team aimed to prevent oxidation by introducing a 'fixing element' that immobilizes oxygen physically adsorbed on the copper surface. Through first-principles calculations investigating various candidate fixing elements, silicon (Si) was theoretically identified as the most suitable element, and it was further demonstrated that a strong bond among silicon (Si), oxygen (O), and copper (Cu) elements?referred to as "Si-Cu-Ox" (Saicox)?forms at the surface’s single atomic layer.

Experimental verification of the theoretical calculations showed that single-crystal copper surfaces with deposited silicon (Si) resisted oxidation even at 400°C, and general copper foils with silicon deposition prevented oxidation up to around 300°C. Additionally, high-temperature oxidation (400°C) suppression was confirmed in various metals such as iron (Fe) and nickel (Ni).

Specifically, the research team revealed that when silicon (Si) is atomically deposited on the copper surface via the ASE method, it intervenes between the weakly bonded copper and oxygen to form a strongly bonded layer (Si-Cu-Ox, Saicox), effectively blocking oxidation at high temperatures.

Copper boasts excellent electrical conductivity with a resistivity of 1.72×10^-6 Ω·cm. Many assume that gold (Au) has lower electrical resistivity, but in reality, gold’s resistivity of 2.44×10^-6 Ω·cm is higher than copper’s. Nevertheless, gold is widely used in various fields due to its resistance to oxidation and stability at high temperatures. However, gold’s high cost remains a significant limitation.

Technologies chemically coating copper surfaces to suppress oxidation at around 60°C were reported in 'Nature' in 2022, highlighting that high-temperature oxidation of copper remains a critical challenge. However, such surface coating methods increase electrical resistance, limiting the preservation of copper’s excellent electrical properties. Furthermore, alloying technologies developed in materials science may be effective in preventing oxidation but face difficulties in maintaining electrical conductivity. Therefore, an innovative alternative capable of solving copper’s oxidation problem while preserving its intrinsic properties was needed.

The research team previously succeeded in growing two-dimensional copper thin films without grain boundaries by developing the ASE method. In this study, the ASE method was applied to deposit Si particles very uniformly on any form of copper surface?whether copper thin films, copper foils, copper deposited on polymers, or rough polycrystalline surfaces?forming the Saicox layer. The atomic single-layer film (Saicox) formed on the topmost surface effectively blocked oxidation at high temperatures while maintaining copper’s inherent electrical properties.

This study presents an innovative technology that introduces an atomic single-layer barrier film to effectively block high-temperature oxidation while nearly preserving copper’s electrical properties, expected to significantly expand the potential use of copper in electrode materials in the future.

The invention of the Saicox layer, which blocks high-temperature oxidation up to 400°C by depositing Si, was published online on February 8 in the world-renowned materials science journal 'Nature Communications' under the title "An impermeable copper surface monolayer with high-temperature oxidation resistance."

This research was supported by the Samsung Future Technology Development Program and the Ministry of Science and ICT, conducted jointly by Professor Emeritus Jeong Se-young of the Department of Optical Mechatronics Engineering at Pusan National University, Professor Kim Young-min of the Department of Energy Science at Sungkyunkwan University, and Professor Kim Sung-gon of the Department of Physics and Astronomy at Mississippi State University as corresponding authors; with Dr. Kim Soo-jae from the Single Crystal Research Institute at Pusan National University and Dr. Kim Young-hoon of the Department of Energy Science at Sungkyunkwan University (currently a postdoctoral researcher at Oak Ridge National Laboratory, USA) as co-first authors.

Professor Jeong Se-young of the Department of Optical Mechatronics Engineering at Pusan National University stated, “Copper oxidation has been considered one of the serious challenges in materials engineering and industry, with oxidation problems worsening as temperature rises and almost no solutions available. The results of this study will bring a very revolutionary advancement to the materials and industrial fields that use copper for various purposes.”

(From left) Professor Jeong Se-young, Professor Kim Young-min, Professor Kim Sung-gon, Professor Kim Soo-jae, Dr. Kim Young-hoon.

(From left) Professor Jeong Se-young, Professor Kim Young-min, Professor Kim Sung-gon, Professor Kim Soo-jae, Dr. Kim Young-hoon.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.