Optimal Conductive Agent Applied to Dry Electrode Design Achieves World-Class Capacity and Output

Five Times Thicker Than Conventional Electrodes, Faster Charging Speed

Published in Energy Environ. Sci.

A battery electrode capable of making a round trip between Seoul and Busan on a single charge has been developed.

Professor Kyungmin Jeong's team from the Department of Energy and Chemical Engineering at UNIST succeeded in developing a battery electrode five times thicker than existing ones through a dry process.

Research team (from the bottom left, counterclockwise) Researcher Kyusang Kim, Professor Kyungmin Jeong, Researcher Hyesung Oh (first author), Researcher Jiyoon Bang, Researcher San Kim. Provided by UNIST

Research team (from the bottom left, counterclockwise) Researcher Kyusang Kim, Professor Kyungmin Jeong, Researcher Hyesung Oh (first author), Researcher Jiyoon Bang, Researcher San Kim. Provided by UNIST

Applying this dry electrode increases battery capacity while maintaining fast charging speeds. Since the dry process does not use chemical solvents, it is also expected to contribute to environmental protection.

With the popularization of electric vehicles, the need for large-capacity lithium-ion batteries has grown, and electrode design that maximizes thickness?directly related to capacity?and reduces the proportion of components unrelated to capacity has gained attention. However, the conventional wet electrode manufacturing method involves dissolving powder-form electrode materials in solvents, which tends to cause agglomeration during solvent evaporation, limiting the thickness of the electrodes.

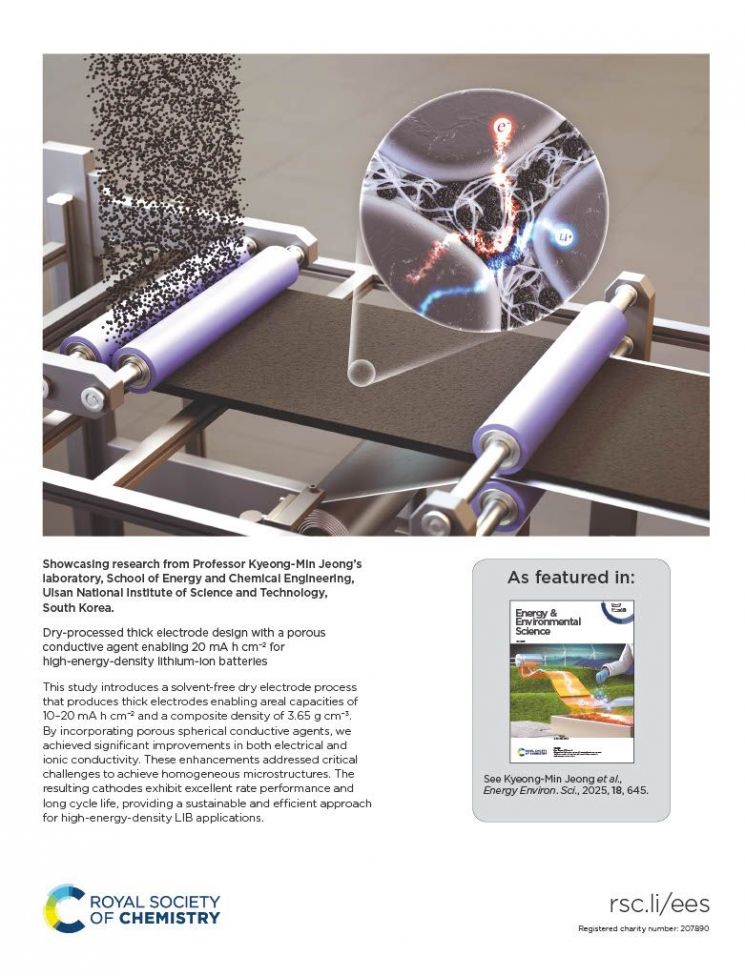

The research team developed electrodes five times thicker than existing ones through a dry manufacturing process. The composite layer density of these electrodes reaches 3.65 g/cm³. Composite layer density refers to the density of the raw materials directly related to capacity. The areal capacity of the electrode is also 20 mAh/cm², five times that of commercial electrodes.

When the developed electrode is applied to batteries, it can increase the driving range of electric vehicles by about 14%. Professor Kyungmin Jeong said, “With existing electric vehicle batteries, a round trip between Seoul and Busan was difficult, but applying this technology makes driving over 600 km possible, enabling a round trip between Seoul and Busan on a single charge.”

Additionally, this electrode contains highly conductive porous spherical conductive materials, enabling fast battery charging speeds. Generally, as electrodes become thicker, the distance lithium ions travel increases, reducing the output?the amount of electricity that can be drawn per unit time?and consequently slowing charging speeds. Special materials like porous spherical conductive agents can compensate for this drawback, but they have been difficult to use in conventional wet processes.

First author researcher Hyesung Oh explained, “This technology is an innovative achievement that simultaneously realizes increased capacity and improved performance of environmentally friendly dry electrodes. It is also significant that performance was verified not only at the coin cell laboratory level but also in 1Ah-class pouch cells applicable to large-scale production processes.”

This research was published on January 21 as the backcover paper in Energy & Environmental Science (IF 32.4), the most prestigious journal in the energy field.

The research was conducted through the creative convergence research project “Development of Material and Process Innovation Convergence Solutions for Carbon-Neutral High-Energy-Density Batteries,” supported by the National Research Council of Science & Technology (NST).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.