Factory Operating Rate Drops to 40%: Foundry Owner Says,

"After 27 Years, This Is the Toughest Time Yet"

Elevator Industry Faces 35-40% Drop in Demand:

"The Real Crisis Hits in the Second Half, No Breakthrough in Sight"

Lighting Industry Warns:

"No Solution Without New Orders, Few Companies Operating Normally"

Small and medium-sized enterprises (SMEs) are being pushed to the brink of collapse due to the prolonged downturn in the construction industry and ongoing political instability.

Even when factory operating rates are reduced due to rising raw material prices and electricity costs, expenses continue to increase. Although positive responses for support have been obtained from the government through appeals, the National Assembly is not functioning normally, and bill reviews are not proceeding on time, causing great anxiety among SME owners.

Kim Dong-hyun, CEO of Korea Electric Metal, is explaining the casting into which molten metal has been poured and solidified. Photo by Kim Jong-hwa

Kim Dong-hyun, CEO of Korea Electric Metal, is explaining the casting into which molten metal has been poured and solidified. Photo by Kim Jong-hwa

Kim Dong-hyun, CEO of Korea Gijeon Metal, which operates a casting factory in Gimpo City, Gyeonggi Province, told reporters on the 14th that the factory’s operating rate was recently lowered to 40%. Although January and February are off-seasons, the factory’s operating rate usually exceeded 60% in previous years, but due to a sharp increase in costs since the end of last year, the operating rate was reduced. Kim said, "I have been running the casting factory for 27 years, and this is the toughest time yet," adding, "Even though we reduced the factory’s operating rate, the electricity bill has increased."

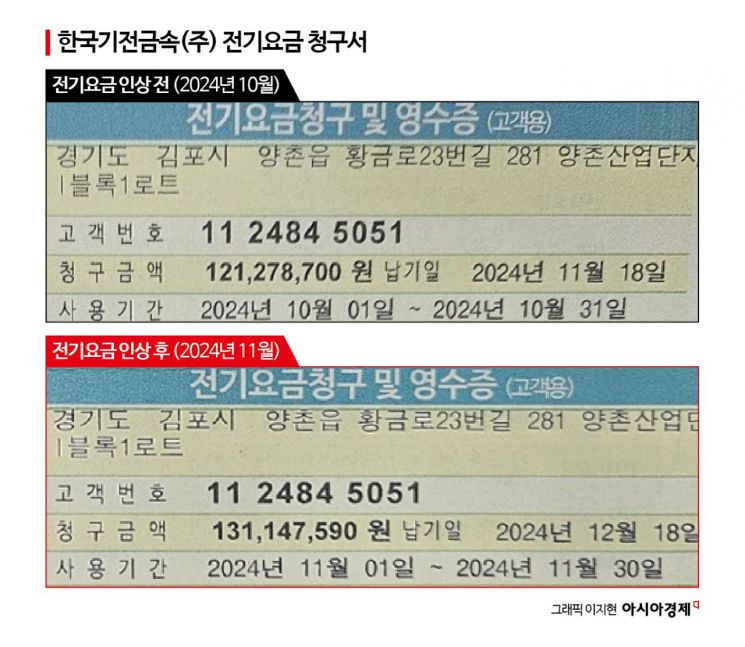

Casting factories must operate electric furnaces to melt molten metal. Korea Gijeon Metal produced 337 tons of cast products (Huran method) in October last year, just before the electricity price hike, and paid 121,278,700 KRW in electricity bills. However, in November, after the electricity price increase, they produced only 128 tons but paid 131,147,590 KRW in electricity bills. Despite producing less than half the amount, the electricity bill increased by 9,868,890 KRW in just one month. The proportion of electricity costs to sales surged from 14.6% in October to 38.6% in November.

Not only electricity bills but also the prices of imported scrap metal and raw materials (carbon, silicon, etc.) have soared due to the sharp rise in the dollar’s value. Kim said, "Overall costs seem to have increased by about 45% due to rising electricity and raw material prices," adding, "There are about 2,000 casting factories nationwide, but only about 1,500 are operating normally. The situation is very worrying."

Due to the prolonged downturn in the construction industry, downstream industries such as elevators and lighting are heading toward an inability to operate normally. According to the most recent statistics from the Statistics Korea’s 'November Industrial Activity Trends,' the 'construction performance,' a representative coincident indicator of the construction industry that reflects construction work achievements up to a certain point, decreased by 0.2% compared to the previous month. It has declined for seven consecutive months from May to November last year, marking the longest consecutive decline since the six-month drop from January to June 2008.

The planned apartment supply volume for this year is also at its lowest. According to Real Estate R114, the nationwide planned apartment supply volume for this year is 146,130 units, significantly lower than the previous lowest record of 172,670 units in 2010, marking an all-time low. Moreover, 48,227 units, accounting for 33% of the total, have not even scheduled their sales dates yet.

The elevator industry, which is typically affected by the construction industry with a lag of six months to a year, is struggling. Since Russia’s invasion of Ukraine in 2022, the prices of steel and stainless steel, the main materials for elevator manufacturing, have risen by about 40% per kilogram, and expected demand this year has decreased by 35-40%. To make matters worse, the Korea Elevator Safety Agency is pushing for a 29% increase in elevator installation inspection fees, causing backlash from the industry.

Kim Yoon-yong, Executive Director of the Korea Elevator Industry Cooperative, said, "With almost no new orders, we are barely surviving on replacement demand for old elevators, and the number of companies struggling to operate normally is increasing," adding, "The real crisis will begin in the second half of this year when order backlogs are empty. It’s a nightmare. There is no sign of a breakthrough."

Elevator technicians are inspecting the electrical system during an elevator safety check at a subway station in Seoul. Photo by Jo Yong-jun

Elevator technicians are inspecting the electrical system during an elevator safety check at a subway station in Seoul. Photo by Jo Yong-jun

The lighting industry is also being pushed to the brink of collapse. The lighting industry, which experiences the effects of the construction downturn about three years later than other sectors, must endure hardship until next year even if the economy recovers this year.

The Korea Smart Lighting Cooperative, which had about 120 SME members until the year before last, saw its membership drop to 108 last year and is feared to shrink further to about 90 this year. This is because more members are leaving the cooperative as they cannot afford the monthly membership fee of 70,000 KRW.

A representative of the Korea Smart Lighting Cooperative said, "In the past, fluorescent lamps were used for about three years, but now they last over ten years. Without new orders such as bulb replacements, there is no solution," adding, "Since companies cannot pay employee salaries, the industry situation is dire, with very few companies operating normally."

In this situation, political uncertainty is further increasing the psychological anxiety of business owners. In November last year, SMEs related to the foundational manufacturing industries such as mold and casting submitted a petition to the government and National Assembly appealing for relief from energy cost burdens, including seasonal and time-of-day electricity rate adjustments.

However, the situation has not improved. Gong Byung-ho, Executive Director of the Gyeonggi Casting Industry Cooperative, lamented, "The government has responded positively to the electricity rate reduction plan, and recently, Representative Kim Nam-geun of the Democratic Party proposed a bill to link energy costs such as electricity fees to delivery prices," adding, "But since bill reviews cannot proceed properly, it is very frustrating."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)