Last August, a passenger car driving through the heart of Yeonhui-dong, Seodaemun-gu, fell into a sinkhole, causing serious injuries to two occupants. In September, two trucks also fell into a sinkhole in Busan, highlighting the recent increase in sinkhole incidents.

Sinkholes often occur due to cracks and damage in aging sewer pipelines. The Korea Land and Geospatial Informatix Corporation estimates that 4.2 out of every 10 sinkhole accidents are caused by such issues. Leakage from sewer pipelines erodes the surrounding soil, creating empty spaces that lead to sinkholes.

The Korea Institute of Civil Engineering and Building Technology (hereinafter referred to as KICT) announced on the 6th that it has developed a trenchless rehabilitation technology for aging sewer pipelines called the “Flexible Sewer Pipeline Trenchless Rehabilitation Method” to address these sinkhole problems.

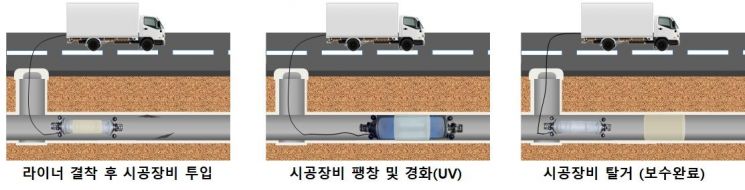

Conceptual diagram of partial repair construction process for sewer pipelines. Provided by Korea Institute of Civil Engineering and Building Technology.

Conceptual diagram of partial repair construction process for sewer pipelines. Provided by Korea Institute of Civil Engineering and Building Technology.

The rehabilitation method was developed as a reinforcement technology that minimizes liner (a cured rehabilitation pipe formed by inserting a tube impregnated with thermosetting resin into the existing pipeline and curing it on-site) detachment and reduction of flow cross-sectional area during rehabilitation.

This method enhances the elasticity of the reinforcement material by more than 20% by attaching acrylic fibers to the existing fiberglass reinforcement.

Additionally, it reduces the thickness of the reinforcement liner by up to 50% while allowing it to respond to pipeline deformation. The driving part of the construction equipment is designed with a five-link structure to ensure it always remains centered in the pipeline, even when the pipeline is deformed.

This improves the liner’s adhesion and durability. The research team emphasized that this method offers the advantage of stable construction without detachment even in severely deformed pipelines.

Furthermore, by deriving an optimal laminated structure that maximizes the integrated behavior effect between reinforcement materials, the bending elastic modulus of the liner has increased more than eightfold compared to previous methods, according to the research team.

This is expected to minimize the reduction in pipeline capacity by halving the liner thickness compared to the existing CIPP method (a method that structurally reinforces existing pipes by curing thermosetting resin on-site) and contribute to mitigating flood damage during heavy rainfall.

Park Seon-gyu, president of KICT, stated, “The flexible pipe reinforcement lining method is designed to effectively rehabilitate aging flexible pipelines stably. In the future, this method will play an important role in protecting public safety by helping prevent the rapidly increasing sinkhole accidents.”

Meanwhile, this research was conducted as part of the Ministry of Science and ICT-supported KICT R&D reserve fund project titled “Development and Demonstration of a High-Strength Photocurable Trenchless Partial Rehabilitation Method Responsive to Sewer Pipeline Deformation.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.