UNIST Professor Lee Ji-seok's Team Develops High-Resolution Color Patterning Technology Based on Silver Nanoparticles

Automated Large-Area Mass Production with 98.36% Reading Accuracy, Published in Adv. Mater.

When ultraviolet (UV) light is shone on the 50,000 won bill’s Mukpodo pattern, fluorescent colors appear. This is hidden anti-counterfeiting information intended for experts such as those in the financial industry.

Items requiring high security contain ‘hidden anti-counterfeiting information’ known only to industry insiders. Recently, domestic researchers have attracted attention by newly developing such hidden anti-counterfeiting technology.

The research team led by Professor Lee Ji-seok of the Department of Energy and Chemical Engineering at UNIST (Park Jong-rae) developed hidden anti-counterfeiting technology using silver nanoparticles.

Researchers (from left) Seong Sanggyun, Ryu Chaeyoung, Yoo Byungcheon, and Professor Lee Jiseok. Provided by UNIST

Researchers (from left) Seong Sanggyun, Ryu Chaeyoung, Yoo Byungcheon, and Professor Lee Jiseok. Provided by UNIST

Professor Lee Ji-seok explained, “This technology is promising for companies to inform customers whether their defective products are counterfeit or not, as well as for anti-counterfeiting of high-value artworks and military supplies that require a high level of security.”

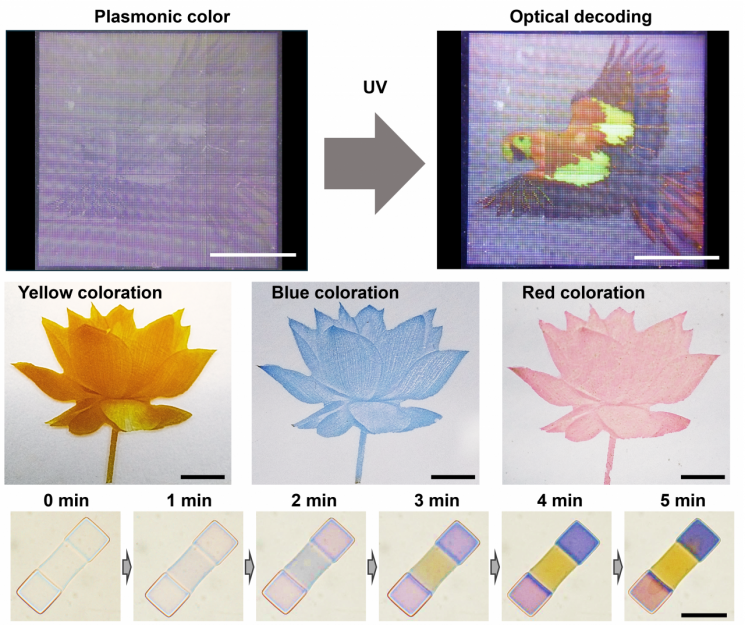

The developed technology cleverly utilizes the disadvantage of silver nanoparticles changing color when exposed to ultraviolet light. To control coloration, the team devised a method of trapping silver nanoparticles within a polymer network to regulate the growth of the nanoparticles. When the network size is large, the silver nanoparticles grow larger and emit light closer to yellow; when the network size is small, the particles are smaller and exhibit a reddish hue. Depending on the composition, the density of the polymer network and the coloration of the silver nanoparticles change when exposed to UV light.

The research team created high-resolution color images by using the polymer structure containing silver nanoparticles as pixels. Using an automated photolithographic printing process that reduces production time to one-tenth of conventional methods, they printed a parrot image larger than half a business card within 30 minutes. Because the process is digital, any desired image can be color printed, and saturation and hue can be precisely controlled.

Additionally, anti-counterfeiting information can be created by arranging the polymer structures in red, yellow, and blue barcode patterns. The coloration changes depending on the UV exposure time, so time information is also stored in the barcode.

By utilizing time information, the amount of data stored can increase more than 1,000 times compared to arrangements using the three primary colors, allowing up to 303 pieces of information to be encoded. There is no need for additional synthesis processes to increase the number of colors, and by continuously arranging barcode particles to form images, the amount of information can be virtually increased infinitely.

The research team developed an artificial intelligence algorithm capable of reading the time information in the barcode, raising the accuracy of authentication to 98.36%. The AI analyzes material composition, UV exposure time, and the actual barcode to determine authenticity.

First author Researcher Yoo Byung-cheon stated, “The manufacturing process is very simple and has excellent color reproducibility, which will greatly aid the development of information encryption systems including anti-counterfeiting.”

The research results were published online on November 20 in the prestigious materials science journal Advanced Materials. The research was supported by the National Research Foundation of Korea.

Anti-counterfeiting information created with developed technology. (Top) Parrot image revealed under UV light, (Middle) Image with adjusted saturation, (Bottom) Barcode array storing time information. Provided by UNIST

Anti-counterfeiting information created with developed technology. (Top) Parrot image revealed under UV light, (Middle) Image with adjusted saturation, (Bottom) Barcode array storing time information. Provided by UNIST

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)