Visiting the Seonamhae Offshore Wind Power Demonstration Complex

Wind Power Efficiency Determined by Operation and Maintenance

Gyeokpo Port at the tip of Byeonsan Peninsula in Buan-gun, Jeonbuk Autonomous Province. After taking a boat for about 30 minutes along the sea route from here, a massive cluster of towering pillars suddenly appeared above the water. As we approached closer, a spectacular scene unfolded with triangular blades on twenty towers, each reaching 90 meters in height, spinning relentlessly in the early winter sea breeze.

The largest commercial offshore wind farm in the southwestern sea of Korea was established in 2019 off the coast of Wido, Buan-gun. The offshore wind farm visited on the 12th had withstood waves and wind for five years, with all 20 turbines generating electricity without major issues. On that day, the average wind speed was 5.67 m/s, and the total power generation reached 287 MWh. This amount of electricity could supply approximately 34,484 households for one day, assuming an average daily consumption of 8.33 kWh per household.

On the 12th, wind turbines were operating at the Southwest Sea offshore wind power complex in Buan-gun, Jeonbuk Province.

On the 12th, wind turbines were operating at the Southwest Sea offshore wind power complex in Buan-gun, Jeonbuk Province. Photo by Oh Hyung-gil

The Southwest Sea offshore wind farm demonstration site consists of 20 wind turbines rated at 3 MW each, totaling 60 MW in capacity. This accounts for about half of the 124.5 MW of commercially operating offshore wind facilities in Korea as of the end of last year. Doosan Enerbility, which supplied the entire wind power system, is also responsible for the O&M (Operation and Maintenance) business.

Yoon Kyung-jin, head of Doosan Enerbility’s Southwest Sea Offshore Wind O&M Office, said, "If there is a problem or breakdown in the equipment that prevents the turbines from operating, all the good wind on days like today is lost." He added, "It is no exaggeration to say that offshore wind power is a seasonal business mainly in winter. Immediate action is required, so it is common to have to head out to sea even on weekends."

As a pillar of carbon-free energy (CFE) that harnesses the wind blowing over the sea to generate electricity, interest is growing not only in the power generation system but also in the O&M business. O&M refers to operation and maintenance, which is directly linked to the utilization rate, a key performance indicator of offshore wind power. If equipment failures cause missed wind hours, the utilization rate inevitably drops. No matter how large the towers are, failing to generate electricity on time means lost opportunities.

Compared to Europe, which started wind power early, or China, which secured competitiveness through state-led initiatives, Korea’s wind power technology is considered to lag behind in many aspects. However, Korea’s O&M business competitiveness is regarded as superior to its wind power technology. Timely operation and maintenance are crucial in wind power, and domestic operators maintain resident personnel at wind farms. In Buan alone, eight personnel maintain a vigilant watch.

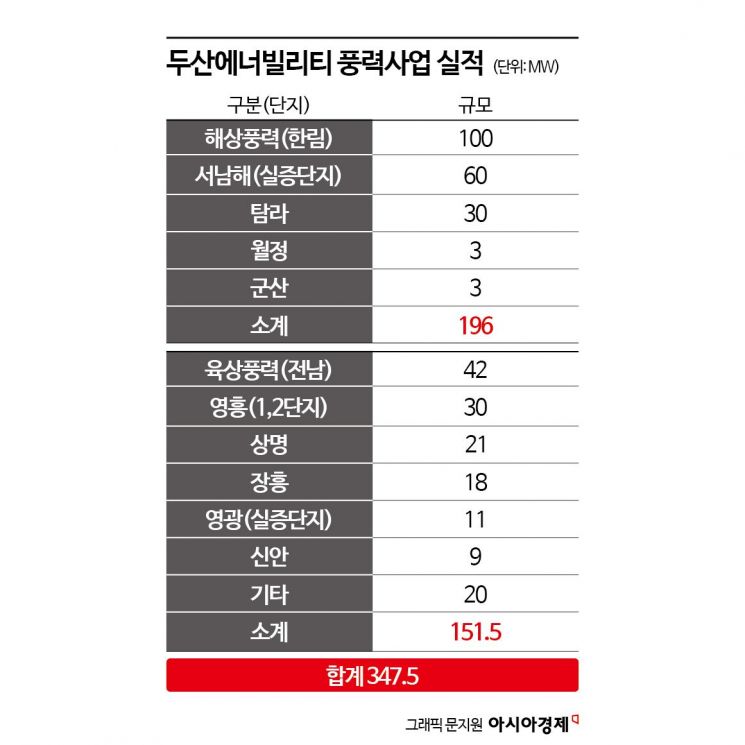

Doosan Enerbility operates wind power farms totaling 347.5 MW, including both onshore and offshore facilities, and is responsible for O&M of 277 MW across eight wind farms. For the Southwest Sea offshore wind farm, Doosan Enerbility will be responsible for O&M until the end of its operational period in 2039.

On the 12th, wind turbines were operating at the Southwest Sea offshore wind power complex in Buan-gun, Jeollabuk-do.

On the 12th, wind turbines were operating at the Southwest Sea offshore wind power complex in Buan-gun, Jeollabuk-do. Photo by Oh Hyungil

Currently, a 24-hour integrated monitoring system is in place to manage and supervise the equipment. They handle everything from planned maintenance to fault repairs. Since work is conducted on towers at sea, it takes about an hour by boat to start operations. This is a demanding task, often involving double or triple layers of difficulty. Yoon said, "In winter, employees almost daily take boats to the site," adding, "Preventive maintenance is the most important to avoid breakdowns."

With the rapid global increase in wind power facilities, the O&M market is also expected to grow steeply. According to the Korea Electric Power Corporation’s Management Research Institute, the cumulative installed wind power capacity worldwide reached 1.2 TW (1.1 TW onshore, 0.1 TW offshore) by last year, and is expected to reach about 3.1 TW (2.6 TW onshore, 0.5 TW offshore) by 2035.

Europe, which started wind power ahead of us, is also increasing repowering?replacing aging facilities with new ones?further expanding the O&M market. In Germany, for example, the number of onshore wind turbines operating for more than 20 years is 12,266, accounting for 40% of all turbines.

Doosan Enerbility has also expanded its business with the offshore wind market growth in mind. It operates Jeju Tamna Offshore Wind Farm, Korea’s first offshore wind farm completed in 2017, and is supplying eighteen 5.5 MW offshore wind turbines for the 100 MW Jeju Hallim Offshore Wind Farm, scheduled for completion by the end of this year.

A 400 MW pilot project is planned to be established offshore near the Southwest Sea offshore wind demonstration site within this year, and Doosan Enerbility is negotiating to supply 10 MW-class equipment it is developing. If the pilot project operates successfully, the capacity will expand to 2 GW. Doosan Enerbility expects to not only supply additional power generation systems but also expand its O&M business.

A company official said, "To efficiently manage offshore wind farms nationwide, we are establishing the Doosan Wind Power Center, an integrated wind power control center, and a wind power maintenance training center in Jeju." He added, "Through remote monitoring, we will be able to increase the operating rate and utilization rate of offshore wind farms."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)