Smart Parts with Embedded Sensors, AI Analysis of Collected Data

AR Digital Twin Implemented for Instant Reactor Status Monitoring

In response to the surge in electricity demand in the era of artificial intelligence, global big tech companies are developing small modular reactors (SMRs).

A remote monitoring technology capable of detecting warning signs of these SMRs within 2 seconds using artificial intelligence has been developed. This technology allows real-time monitoring of the complex internal conditions of SMRs, which is expected to reduce management costs and enhance safety.

A joint research team from UNIST (President Jongrae Park), including Professors Imdu Jeong and Namhoon Kim from the Department of Mechanical Engineering (also affiliated with the Graduate School of AI), and Professor Hyungmo Kim from Gyeongsang National University, developed a smart component system for remote monitoring of SMRs.

Research team. (From the bottom left, counterclockwise) Researcher Kim Ha-yeol, Seo Jun-young, Jeong Hae-gwon, Shin Woo-young, Jeon Hong-ryeong.

Research team. (From the bottom left, counterclockwise) Researcher Kim Ha-yeol, Seo Jun-young, Jeong Hae-gwon, Shin Woo-young, Jeon Hong-ryeong.

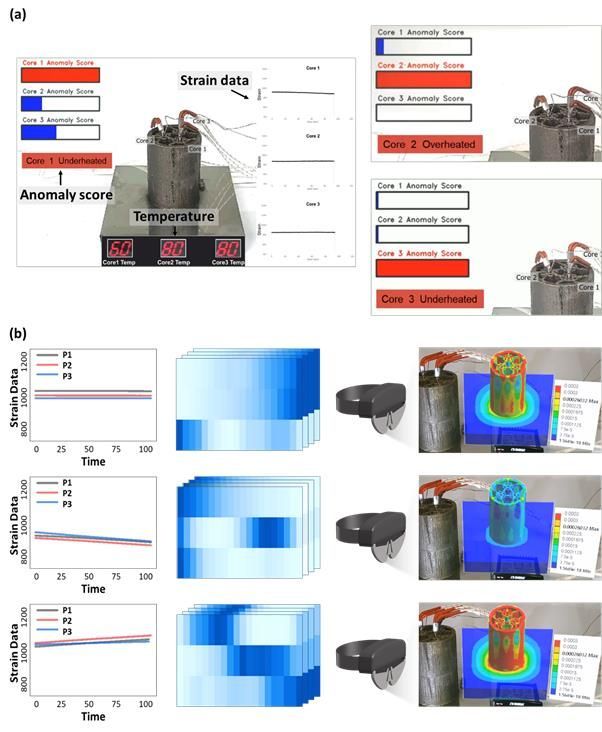

The system works by having smart components embedded with fiber optic sensors collect and transmit data, which AI then analyzes to issue alerts for abnormal conditions.

The core of this system development lies in the technology for manufacturing smart metal components through 3D printing and AI technology that rapidly processes continuous multiple variables from fiber optics simultaneously. The research team precisely fabricated smart nuclear power components using the DED printing method and flexibly embedded fiber optic sensors inside the metal components, enabling stable operation of the parts even in the harsh environment of a reactor.

The AI rapidly and simultaneously processes multiple variables, including thermal deformation information from various positions of the fiber optic sensors, to instantly detect warning signs. These can then be remotely monitored in an augmented reality (AR)-based digital twin environment.

Unlike large reactors, ultra-small reactors are compact and can provide a steady power supply near facilities that require electricity. However, the importance of stable reactor operation increases accordingly.

This technology enables AI to continuously and precisely monitor thermal deformation and warning signs inside the reactor that are difficult for humans to detect, which is expected to significantly contribute to the safety and commercialization of next-generation small modular reactors.

Professor Imdu Jeong stated, “We addressed the challenging and costly inspection methods by integrating AI technology, which can greatly contribute to the stable and efficient operation of next-generation small modular reactors. This integrated technology can also be applied across various industrial fields such as autonomous manufacturing systems, aerospace, and advanced defense.”

The research was published on October 10 in ‘Virtual and Physical Prototyping,’ a leading journal in advanced manufacturing (ranked within the top 7% in JCR).

The research was supported by the Ministry of Science and ICT through the National Research Foundation of Korea, the Institute for Information & Communications Technology Planning & Evaluation, and the Ministry of Trade, Industry and Energy through the Korea Energy Technology Evaluation and Planning Agency.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.