The supercritical carbon dioxide power generation system has reached a turning point in electricity production. Achieving this turning point in a power generation system means that practical electricity production has become possible. In particular, the supercritical carbon dioxide power generation system is gaining attention as a next-generation high-efficiency power generation system, and advanced countries such as the United States and China are fiercely competing in research and development to reach this turning point.

The Korea Atomic Energy Research Institute (hereinafter KAERI) announced on the 23rd that Dr. Cha Chae-eun's research team has completed the development of the ‘supercritical carbon dioxide power generation system’ and, for the first time in Korea, succeeded in reaching the turning point where the produced power exceeds the input power.

It took four years since the research team began experimental development research to achieve this turning point, securing the criteria and operational technology for producing net output in the power generation system. This is significant as it demonstrates world-class technology in the field of fully enclosed supercritical carbon dioxide power generation systems.

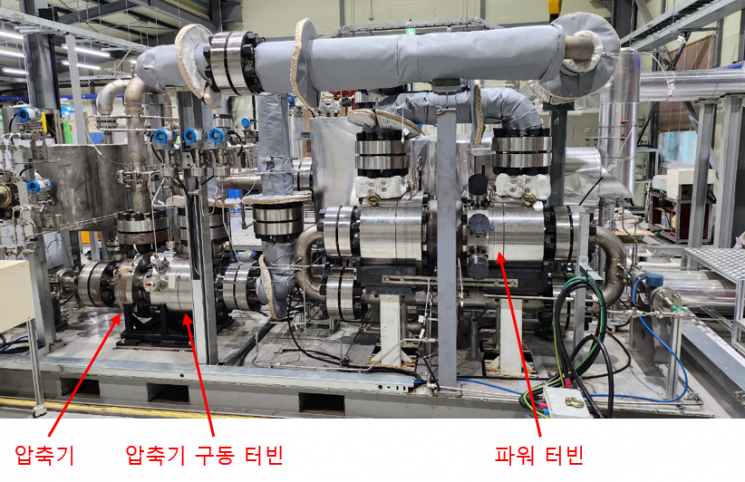

For the supercritical carbon dioxide power generation system test, turbomachinery such as compressors, compressor drive turbines, and power turbines have been installed. Photo by Korea Atomic Energy Research Institute

For the supercritical carbon dioxide power generation system test, turbomachinery such as compressors, compressor drive turbines, and power turbines have been installed. Photo by Korea Atomic Energy Research Institute

Supercritical carbon dioxide power generation produces electricity using carbon dioxide in a supercritical state, which has properties of both liquid and gas. High temperature and high pressure are essential to bring carbon dioxide into a supercritical state. The core components of the supercritical carbon dioxide power generation system include the ‘compressor’ that pressurizes the carbon dioxide, the ‘drive turbine’ that operates the compressor, and the ‘power turbine’ that generates electricity from the carbon dioxide.

The research team first developed the ‘drive turbine’ to operate the compressor and integrated it into the system to enable compressor operation.

Then, after circulating and compressing the carbon dioxide with the compressor drive turbine, they gradually increased the temperature of the external heat source and the carbon dioxide flow rate. When the system was demonstrated under these conditions, it was confirmed that the power generated by the power generation system exceeded the input power, reaching the ‘power production turning point.’

This means that a system has been completed that produces electricity by supplying the force to compress carbon dioxide internally along with the external heat source.

Earlier, in April, the research team succeeded in producing 100 kW of power using supercritical carbon dioxide power generation. At that time, the team focused on demonstrating the ‘power turbine’ that generates electricity, operating the carbon dioxide compressor with an external motor to verify the power generation capability of the system in the supercritical state.

Generally, supercritical carbon dioxide power generation systems below the MWe scale must be sized to fit on a single 20 to 40-ton trailer to be recognized as competitive.

This size is about 1/10 to 1/20 of conventional steam power generation systems, making it a power generation system with the advantage of miniaturization that can be used together with heat sources such as next-generation reactors, solar heat, ship exhaust heat, and coal-fired power.

Carbon dioxide in a supercritical state has a high density like a liquid, providing stronger force to rotate turbines than ordinary steam, which is advantageous for reducing the size of the power system. Additionally, as a gas, it experiences less loss due to friction and is free from corrosion issues, which are also benefits.

Dr. Cha (principal researcher) said, “Based on this turning point achievement test, KAERI has reached a stage where it can successfully develop fully enclosed high-efficiency supercritical carbon dioxide power generation technology for the first time in Korea. KAERI will continue research to achieve a total output goal of 500 kW and develop MW-class power generation systems.”

Meanwhile, this research was conducted as a joint study by a consortium led by KAERI, including Jinsol Turbo Machinery Co., Ltd., Korea Advanced Institute of Science and Technology (KAIST), Pohang University of Science and Technology (POSTECH), and others.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)