A cryogenic turbo expander has been developed using domestic technology. The cryogenic turbo expander is a device necessary for liquefied storage of alternative energy. This device operates on the principle of expanding high-pressure gas with an impeller to lower the temperature. Until now, there has been a high dependence on overseas sources, but with the acquisition of core technology, localization is expected to be possible in the future.

The Korea Institute of Machinery and Materials (hereinafter referred to as KIMM) announced on the 14th that the research team led by Principal Researcher Hyungsoo Lim of the Energy Storage Laboratory recently developed an oil-free cryogenic (temperature between absolute 123K (minus 150℃) and absolute 0K (minus 273℃)) turbo expander using Zero GWP (Global Warming Potential) refrigerant and completed demonstration testing of the expander for natural gas liquefaction.

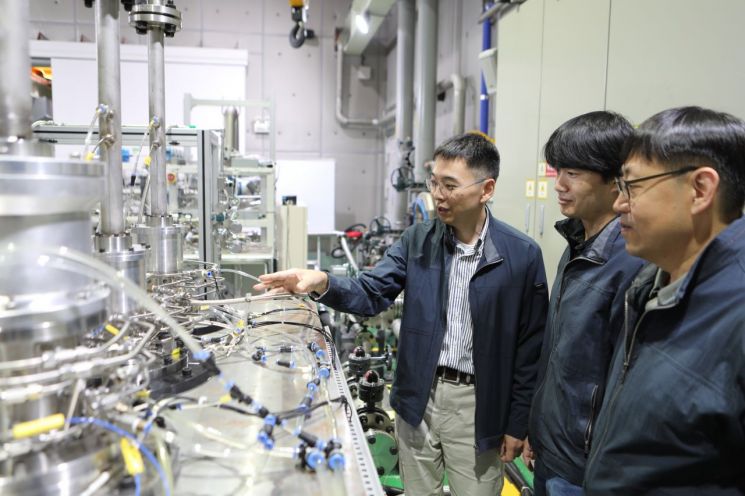

Im Hyeong-su, Senior Researcher (first from the left), is explaining the operating principle of the cryogenic turboexpander used for air liquefaction. Photo by Korea Institute of Machinery and Materials

Im Hyeong-su, Senior Researcher (first from the left), is explaining the operating principle of the cryogenic turboexpander used for air liquefaction. Photo by Korea Institute of Machinery and Materials

The cryogenic turbo expander developed by the research team operates at temperatures below minus 183 degrees Celsius. To cool alternative energy to cryogenic temperatures below minus 183 degrees Celsius, the team independently developed components such as the impeller, oil-free bearings, shaft, and casing.

They also secured core technologies including rotational stability, output control, and insulation design, successfully cooling neon, a Zero GWP refrigerant, from room temperature to below minus 183℃.

The cryogenic turbo expander, which rotates tens of thousands to hundreds of thousands of times per minute, has so far been mostly dependent on imports. However, with KIMM’s technological development, the possibility of domestic production has been established.

In particular, existing expanders used oil-lubricated bearings requiring separate oil supply systems and had complex structures, but the expander developed by KIMM applies an oil-free method, making the structure simpler and smaller, which is advantageous for application even in small-scale industrial sites.

Based on this, the research team has currently developed expanders for hydrogen liquefaction, natural gas liquefaction, and air liquefaction, respectively.

Among these, the natural gas liquefaction expander can operate at minus 183℃ with a refrigeration capacity of 7 to 10 kW, and commercialization procedures are underway with companies.

Principal Researcher Hyungsoo Lim of KIMM said, “Storing alternative energy such as hydrogen in a cryogenic liquid state greatly increases energy density, which can drastically reduce the size of storage facilities. Above all, the development of core technology for cryogenic turbo expanders is expected to enable localization of alternative energy storage systems to respond to climate change.”

Meanwhile, this research was conducted with support from KIMM’s basic projects and the Ministry of Land, Infrastructure and Transport’s Land, Infrastructure and Transport Science Technology Promotion Agency.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)