Collaboration with Local AI Companies

World's First 'AI Non-Destructive Testing' Automated Evaluation Solution

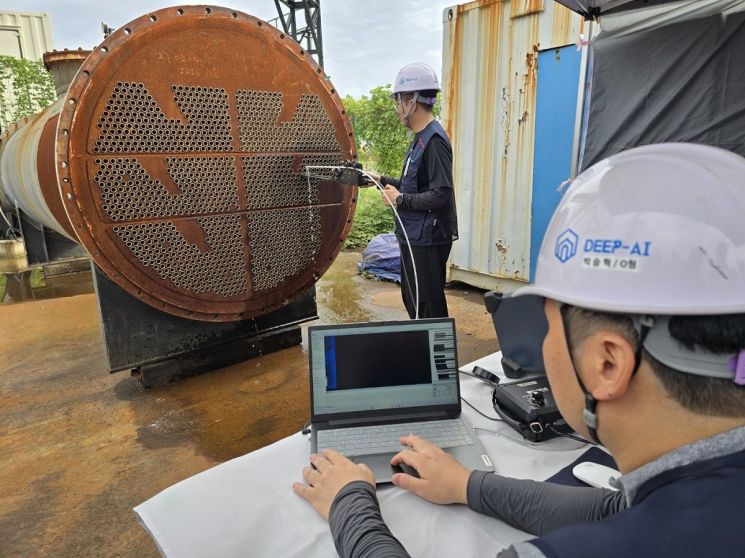

SK Innovation and local AI company DEEP AI, which developed the world's first 'AI Non-Destructive Inspection (IRIS) Automatic Evaluation Solution,' are conducting defect inspections of heat exchangers. Photo by SK Innovation

SK Innovation and local AI company DEEP AI, which developed the world's first 'AI Non-Destructive Inspection (IRIS) Automatic Evaluation Solution,' are conducting defect inspections of heat exchangers. Photo by SK Innovation

SK Innovation is developing solutions that apply artificial intelligence (AI) and digital transformation (DT) technologies to refining and petrochemical processes for the first time in Korea, expanding these as new future growth engines.

According to industry sources on the 29th, SK Innovation is collaborating with local AI company DEEP AI to develop and commercialize the world's first 'AI Non-Destructive Testing (IRIS) Automated Evaluation Solution.' Since 2016, SK Innovation has integrated AI and DT into the smart plant initiatives at SK Ulsan CLX, evolving and advancing to Smart Plant 2.0, and aims to continue producing tangible results going forward.

Supporting the Development of the World's First Equipment Inspection Diagnostic AI Model

The refining and petrochemical processes, which operate 365 days a year, undergo periodic inspections to ensure safe operation, with engineers determining maintenance needs. A representative method is non-destructive testing using ultrasound to detect defects, primarily used for heat exchanger defect inspections. Heat exchangers are core components composed of thousands of tubes used for temperature control during product manufacturing in refining and petrochemical processes. Approximately 7,000 units are installed at SK Ulsan CLX alone, with about 30,000 units across the Ulsan petrochemical industrial complex, indicating widespread use.

The existing inspection method involves capturing ultrasound images and experts visually identifying defects. This method relies on human experience and capability, leading to limitations in accuracy and time required. The decreasing number of experts in the field is also a concern. The AI IRIS technology developed jointly by SK Innovation and DEEP AI uses AI to detect defects by analyzing accumulated data from ultrasound images, achieving over 95% accuracy. The inspection time can also be reduced by more than 90%.

This is a representative case of combining vast technical knowledge and data held by large corporations with AI technology from small and medium enterprises. Notably, the collaboration with a local AI company fosters 'Industrial AI' that leverages the characteristics of the industrial city of Ulsan.

After field verification at SK Ulsan CLX, the solution will be fully applied there and expanded to the Ulsan refining and petrochemical complex as part of commercialization efforts. A representative from SK Ulsan CLX stated, "We plan to further advance the AI Non-Destructive Testing (IRIS) Automated Evaluation Solution with DEEP AI and expand the market not only to the entire domestic refining and petrochemical industry but also to sectors where the same technology applies, such as piping, boilers, tanks, automotive, and aircraft parts. Additionally, we are considering entering overseas markets."

Members of SK Energy are having a meeting using 'OCEAN-H,' an equipment asset management system independently developed by SK Innovation. Photo by SK Innovation

Members of SK Energy are having a meeting using 'OCEAN-H,' an equipment asset management system independently developed by SK Innovation. Photo by SK Innovation

Commercialization of Korea’s First Introduced Smart Plant System… SK Innovation Aims to Make Ulsan the Center of ‘Industrial AI’

SK Innovation has also successfully commercialized its self-developed equipment asset management system, 'OCEAN-H (Optimized & Connected Enterprise Asset Network Hub).' OCEAN-H is a system optimized for the refining and petrochemical industry, implemented using data accumulated over the past 60 years to adapt to various situations.

Since commercializing OCEAN-H early last year, SK Innovation has competed with overseas solutions and secured five refining and petrochemical companies in the Ulsan region as customers, generating approximately 3.5 billion KRW in sales. The system, which improves existing issues and is tailored to domestic conditions, has attracted numerous inquiries and collaboration requests from refining and petrochemical companies. Inquiries have also continued from the power generation, steel, and battery sectors.

An SK representative stated, "Solutions developed by overseas companies had issues such as convenience, usability, scalability, and high costs due to differences in work environments, but our system has significantly improved these aspects, earning high market recognition."

In November 2023, SK Innovation signed a business agreement with TCS (TATA Consultancy Service), a global IT service and software company under the Indian TATA Group, and plans to target global markets including Indonesia, Thailand, Vietnam, and India.

Seokwan Hee, Head of Technology and Facilities at SK Energy, said, "Based on the refining and petrochemical expertise of SK Ulsan CLX, we are securing competitiveness by utilizing various digital technologies such as AI. Since SK Ulsan CLX started the new challenge of introducing Korea’s first smart plant following the country’s first refinery, we will produce definite results."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.